LewDude

0

- Joined

- Jul 16, 2017

- Messages

- 364

- Points

- 63

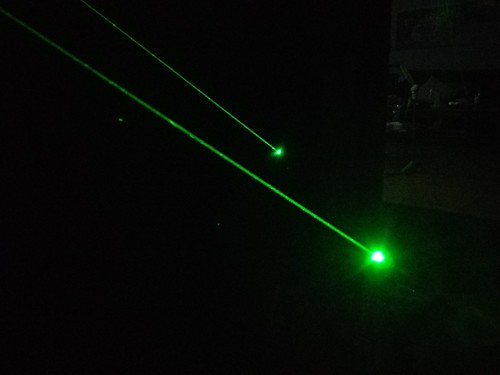

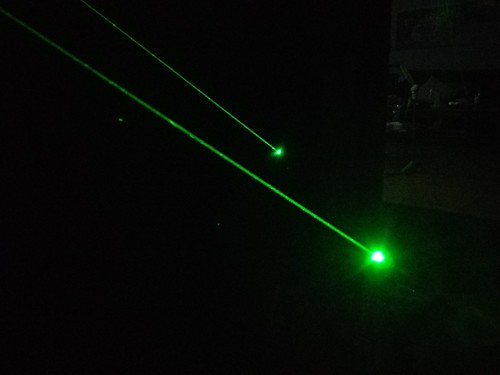

Need to share a couple builds I've done - one was tonight and one was a couple weeks ago...not a full step-by-step this time, but want ya'll to see the pretty things Rich has made!

The 1st host was a 1x10440. I've been making a lot of little boost-driven lasers, and wanted something a bit more powerful. Since we are talking just 1 10440, a boost was still the driver, but I went and maxed out a Pico, then a Flex - with a NUGM01. At around 1.4A - it puts out a decent amount of light!

IMAG2270 by Lewie Wilkinson, on Flickr

IMAG2270 by Lewie Wilkinson, on Flickr

IMAG2271 by Lewie Wilkinson, on Flickr

IMAG2271 by Lewie Wilkinson, on Flickr

With a 3 element glass lens, I'm getting around 500mW of 520nm.

Tonight I put together the Copper 1x14500. Wanting to do something I hadn't done before - I opted to go with 2x14250s and use an Astralist Superdrive V. I have SO many blue builds, I went with another NUGM01 - this time set to 2.2A :wave:.

A couple pics of both hosts and both hosts in action!

IMAG2494 by Lewie Wilkinson, on Flickr

IMAG2494 by Lewie Wilkinson, on Flickr

IMAG2496 by Lewie Wilkinson, on Flickr

IMAG2496 by Lewie Wilkinson, on Flickr

IMAG2512 by Lewie Wilkinson, on Flickr

IMAG2512 by Lewie Wilkinson, on Flickr

IMAG2509 by Lewie Wilkinson, on Flickr

IMAG2509 by Lewie Wilkinson, on Flickr

IMAG2501 by Lewie Wilkinson, on Flickr

IMAG2501 by Lewie Wilkinson, on Flickr

IMAG2504 by Lewie Wilkinson, on Flickr

IMAG2504 by Lewie Wilkinson, on Flickr

Love both of these hosts. The white 10440 obviously will not run very long without overheating, but its fun to have a little white pointer putting out some serious beams!

The modules will likely not live in these hosts forever, but I can say these hosts will bring me much joy no matter what diode/driver/battery combo goes into them. Thanks Lifetime!!!

The 1st host was a 1x10440. I've been making a lot of little boost-driven lasers, and wanted something a bit more powerful. Since we are talking just 1 10440, a boost was still the driver, but I went and maxed out a Pico, then a Flex - with a NUGM01. At around 1.4A - it puts out a decent amount of light!

IMAG2270 by Lewie Wilkinson, on Flickr

IMAG2270 by Lewie Wilkinson, on Flickr IMAG2271 by Lewie Wilkinson, on Flickr

IMAG2271 by Lewie Wilkinson, on FlickrWith a 3 element glass lens, I'm getting around 500mW of 520nm.

Tonight I put together the Copper 1x14500. Wanting to do something I hadn't done before - I opted to go with 2x14250s and use an Astralist Superdrive V. I have SO many blue builds, I went with another NUGM01 - this time set to 2.2A :wave:.

A couple pics of both hosts and both hosts in action!

IMAG2494 by Lewie Wilkinson, on Flickr

IMAG2494 by Lewie Wilkinson, on Flickr IMAG2496 by Lewie Wilkinson, on Flickr

IMAG2496 by Lewie Wilkinson, on Flickr IMAG2512 by Lewie Wilkinson, on Flickr

IMAG2512 by Lewie Wilkinson, on Flickr IMAG2509 by Lewie Wilkinson, on Flickr

IMAG2509 by Lewie Wilkinson, on Flickr IMAG2501 by Lewie Wilkinson, on Flickr

IMAG2501 by Lewie Wilkinson, on Flickr IMAG2504 by Lewie Wilkinson, on Flickr

IMAG2504 by Lewie Wilkinson, on FlickrLove both of these hosts. The white 10440 obviously will not run very long without overheating, but its fun to have a little white pointer putting out some serious beams!

The modules will likely not live in these hosts forever, but I can say these hosts will bring me much joy no matter what diode/driver/battery combo goes into them. Thanks Lifetime!!!