IWIRE

0

- Joined

- Dec 18, 2013

- Messages

- 621

- Points

- 0

Born on 06/12/14

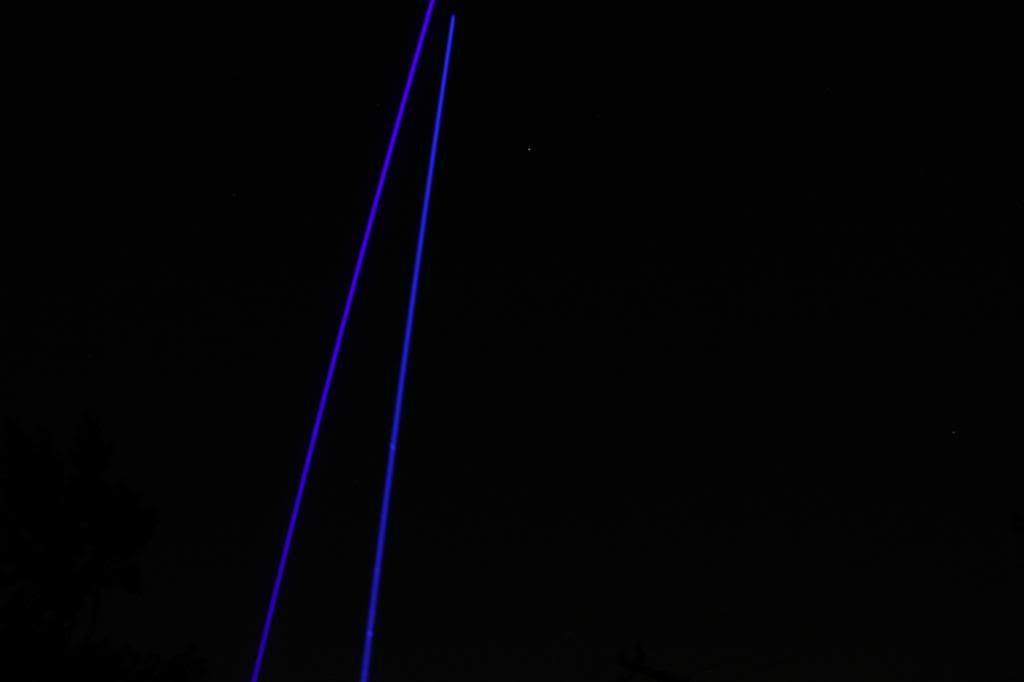

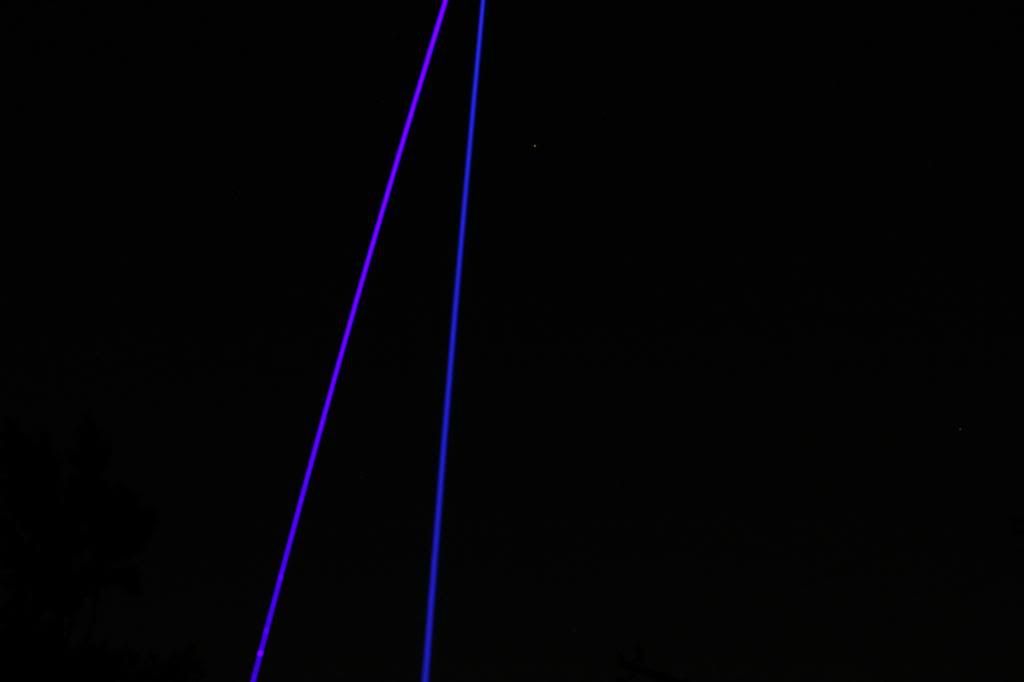

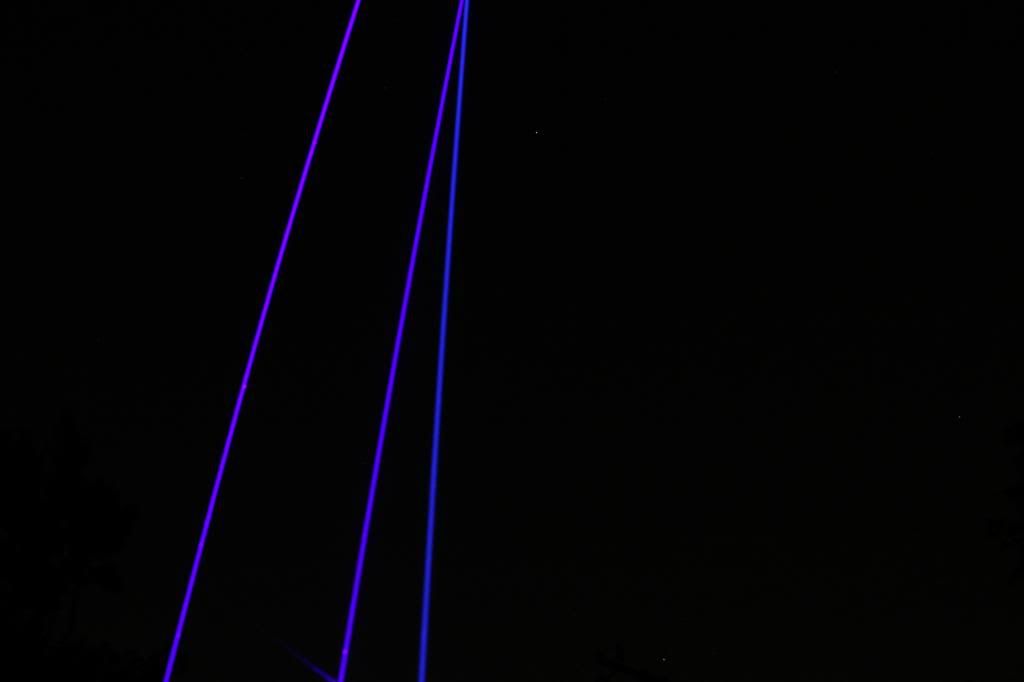

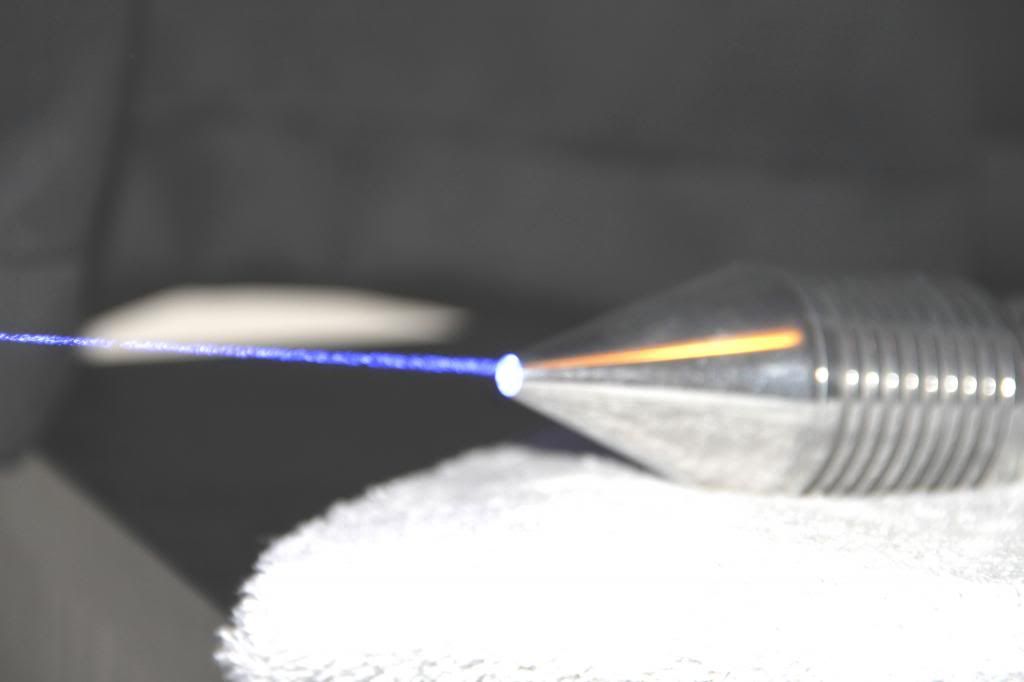

Blue Bayou was brought into the world as a beacon for the full moon tonight on Friday 13th

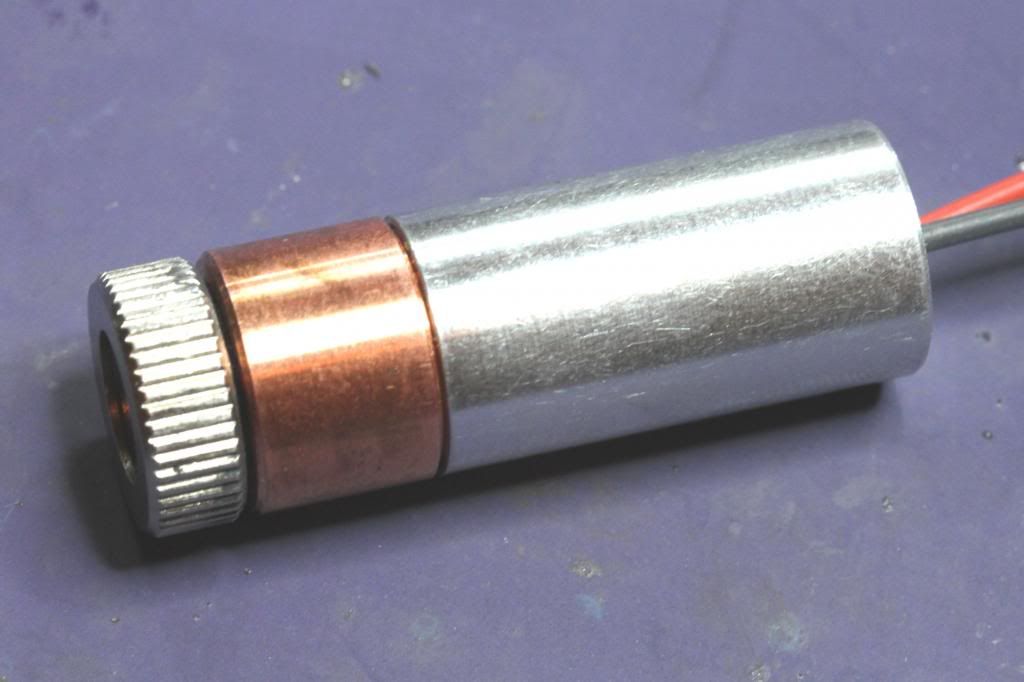

Diode of course from 3 day DTR

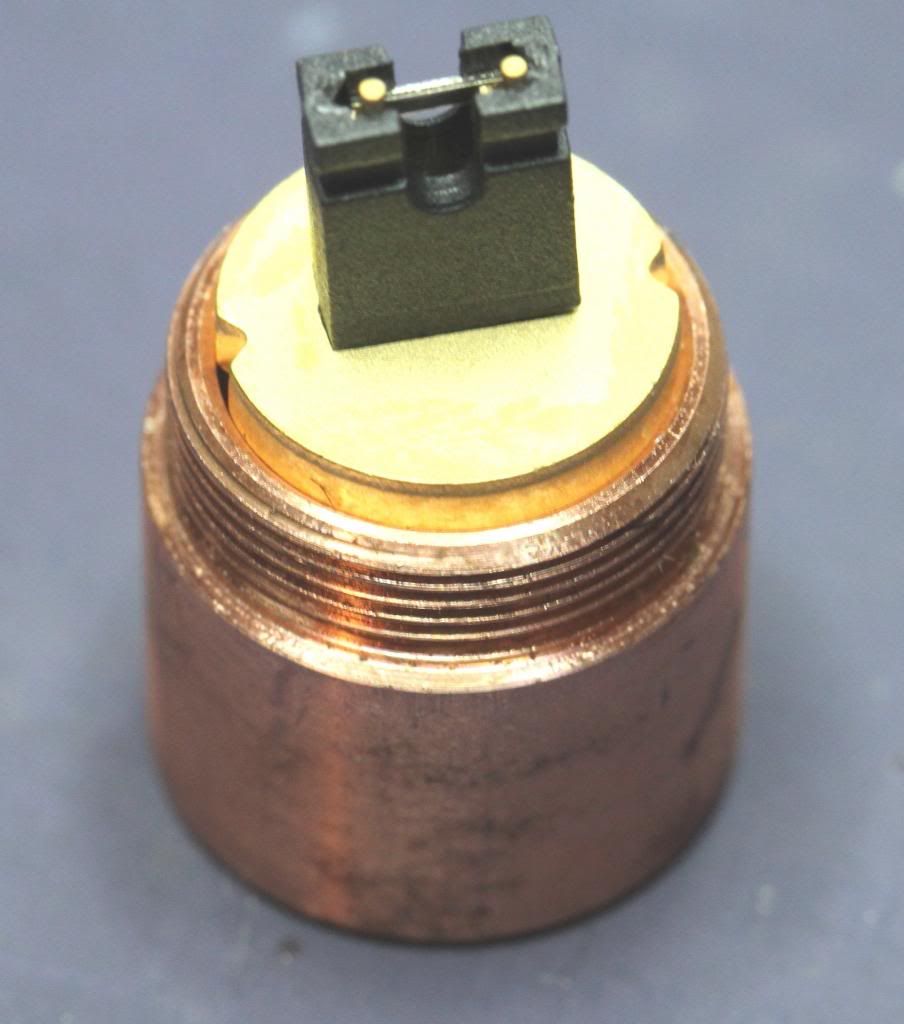

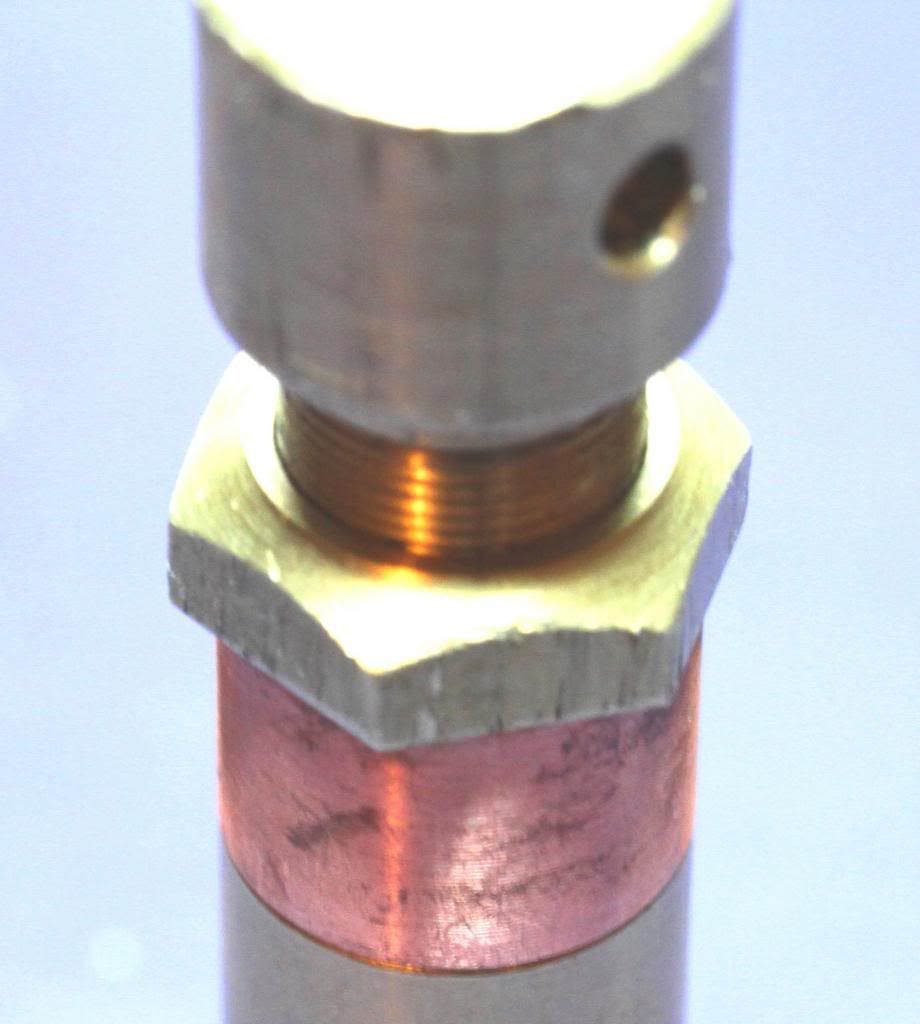

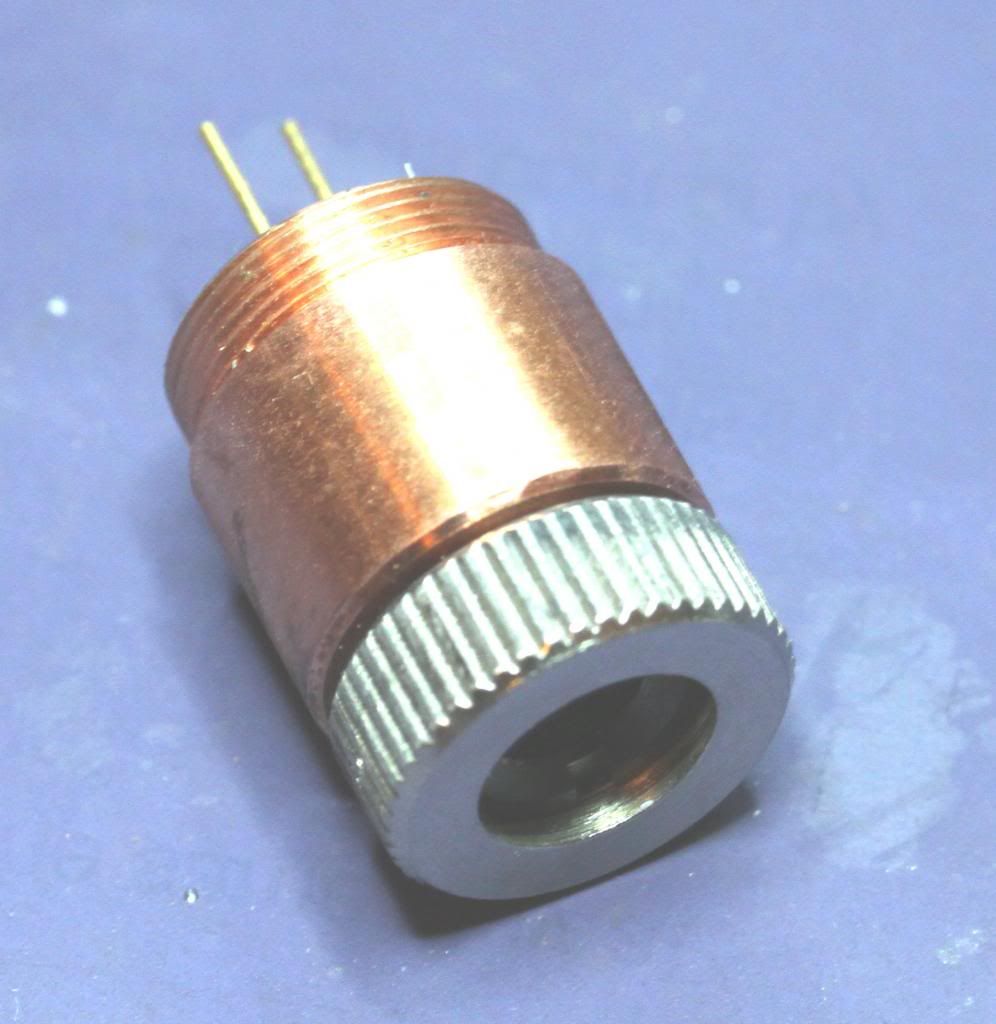

Make sure module fits heatsink

Make sure lens threads into module

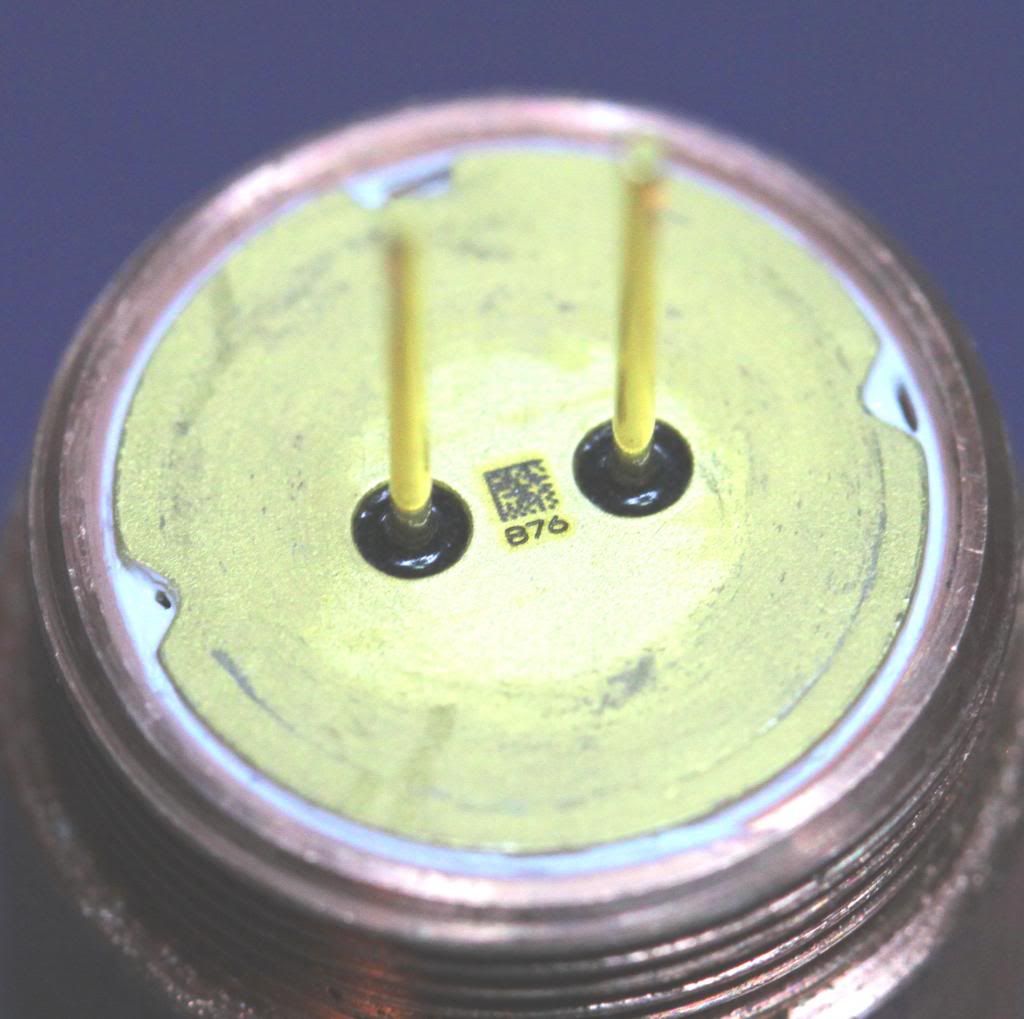

Install the diode in the module :crackup:

Only don't use a hammer, it will bend the pins

Use Flaminpyros press tool and safe a diodes life !

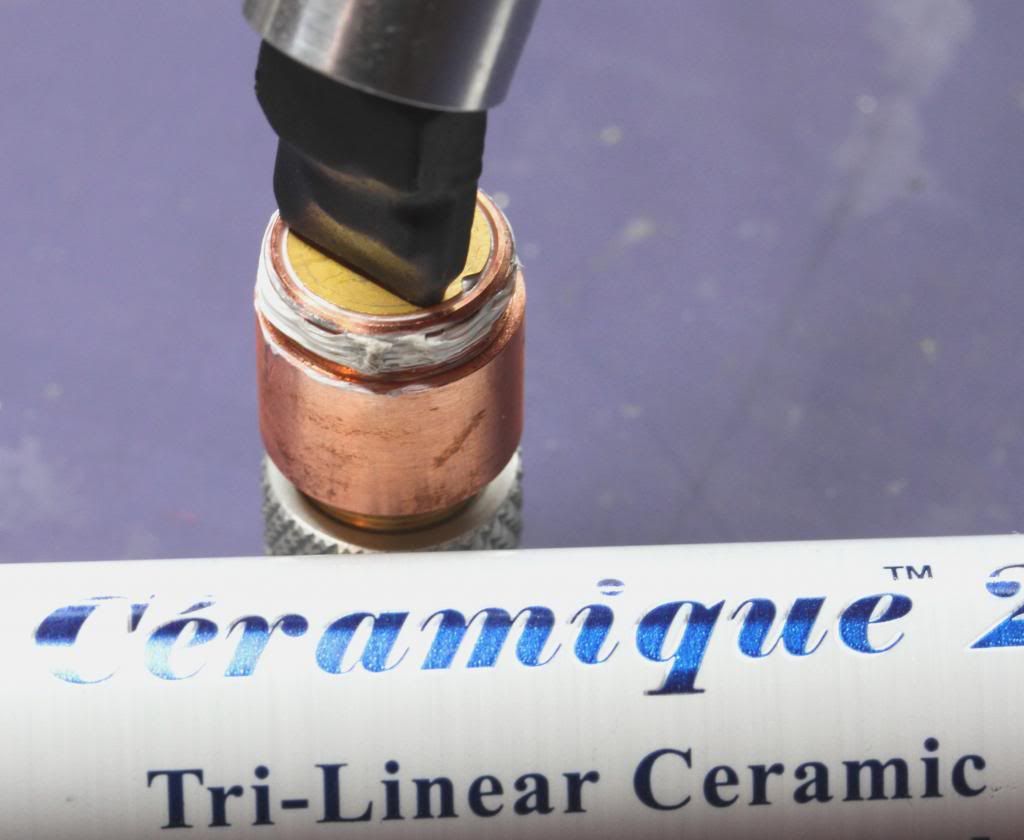

I like to put a little thermal paste on the flange of the diode making sure not to get anything on the face of the diode. Don't set it down on it's face. Don't touch the face. Try not to even look at it's face

Screw the guide sleeve onto the module but leave it slightly loose or you will be cussing after the diode is pressed in. YMMV

Slide the assembly down over the press tool/diode

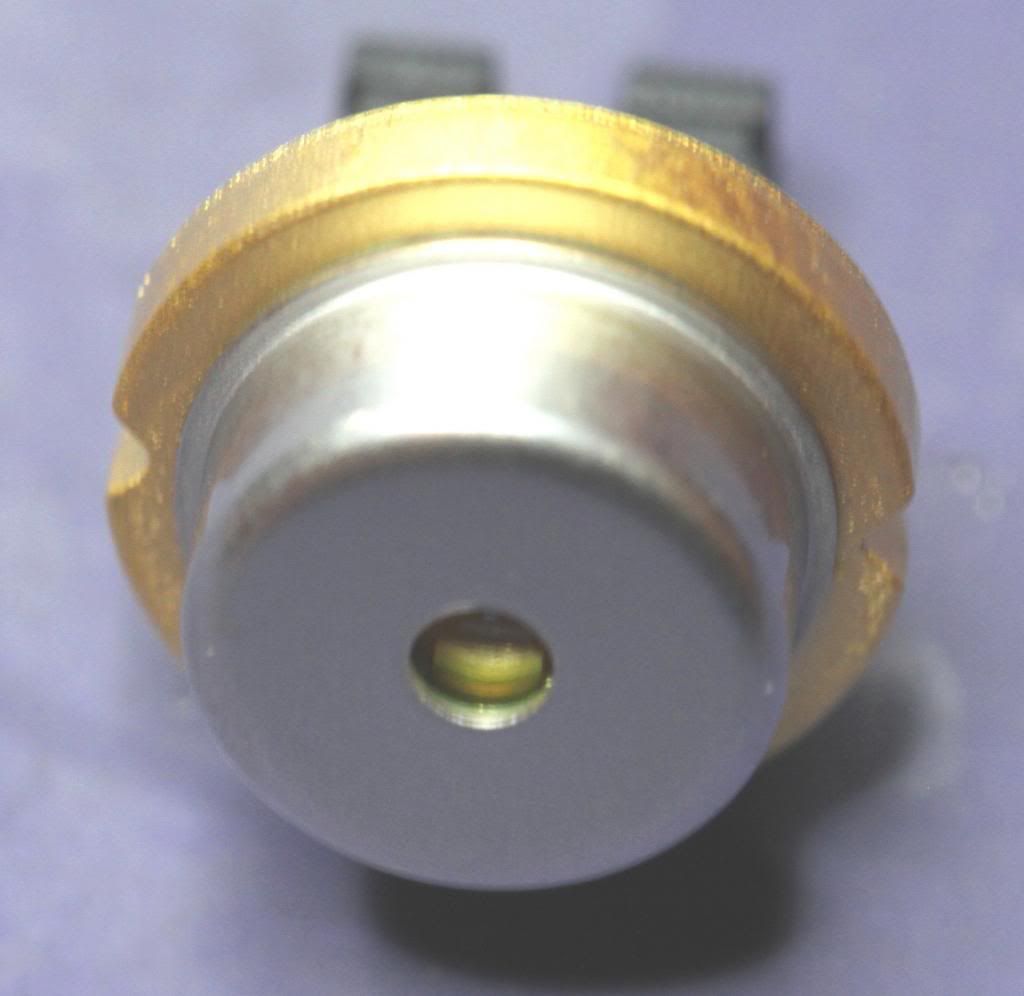

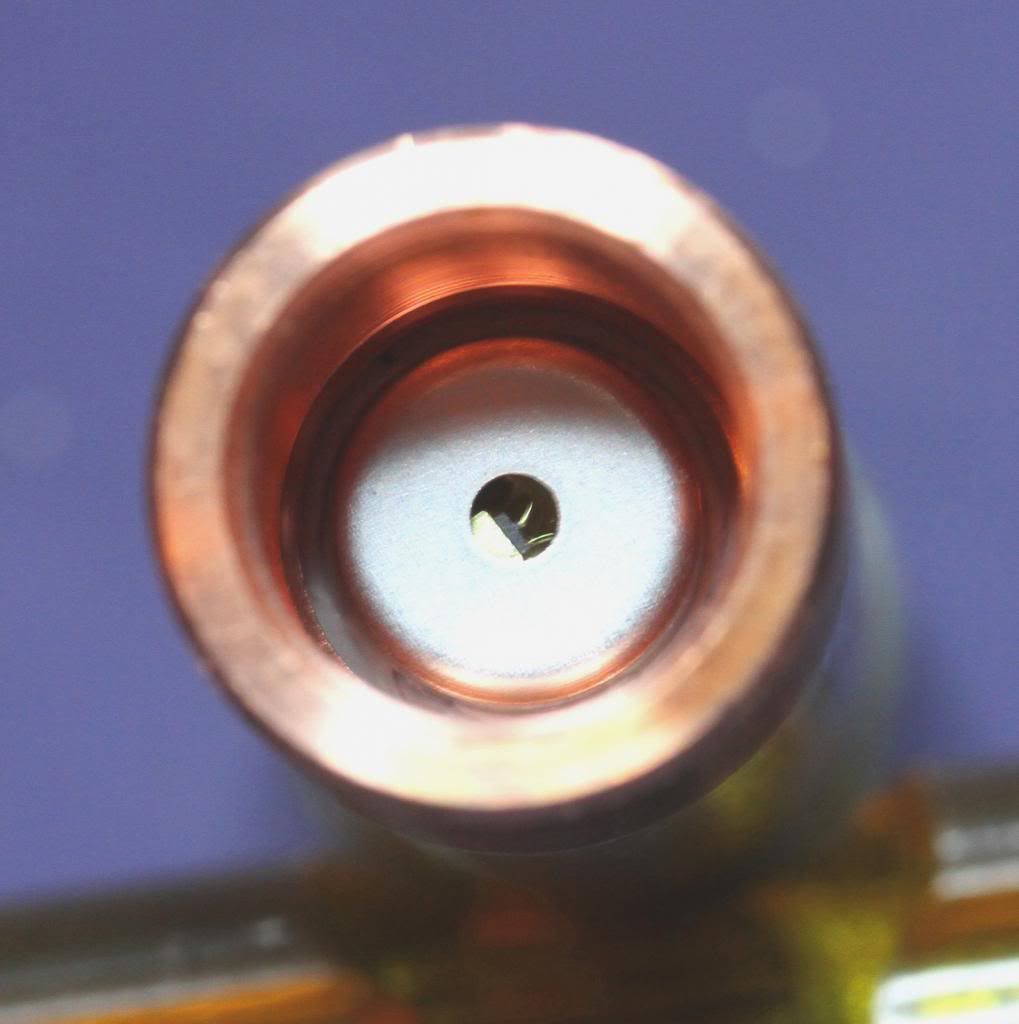

Check and make sure the diode is centered in the module

Remember that lens we test fit earlier ? It would be real nice if it would still thread in after we are through. So I take Flaminpyros stuck module extractor and thread it into the module to save the threads and put the jam nut against the face, making sure I left room for the diode to press in and not hit it :wave:

Then I put the whole assembly in my big azz channel locks, adjusted out so the pressure is square with the tool. I like the pliers because I can feel the diode pressing into place.

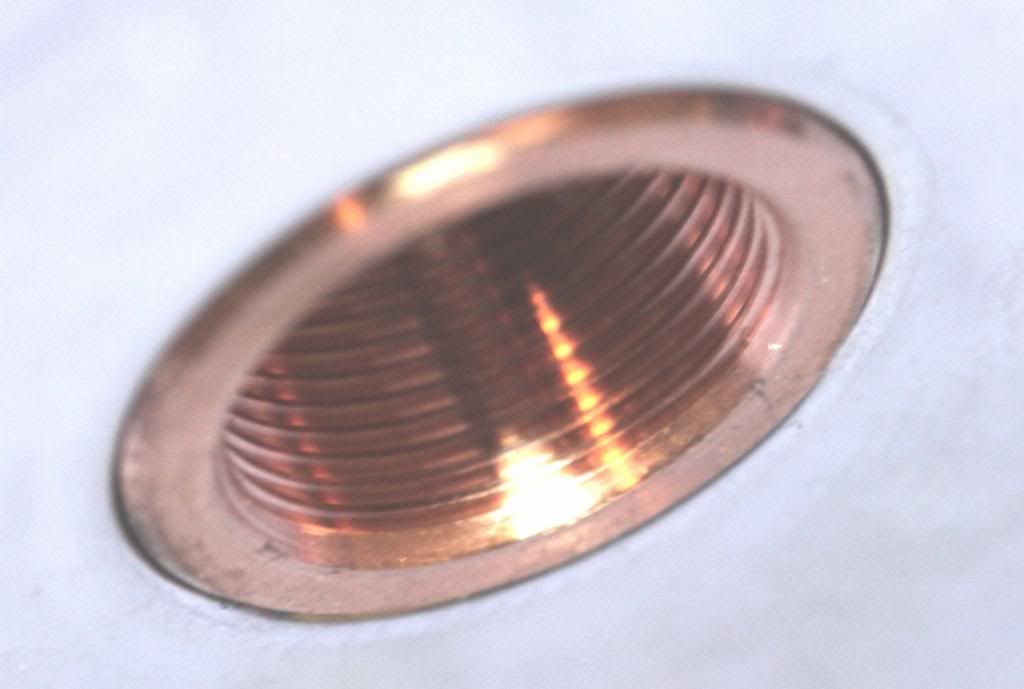

Bam ! Works like a champ everytime ! That's a happy diode right there. Nice and even, slightly below the lip of the module. I've never met Flaminpyro but I'm pretty sure he is a genius, comparatively speaking to me of course

So now I take one of those cheap plastic lens holder things and screw in to keep crude out.

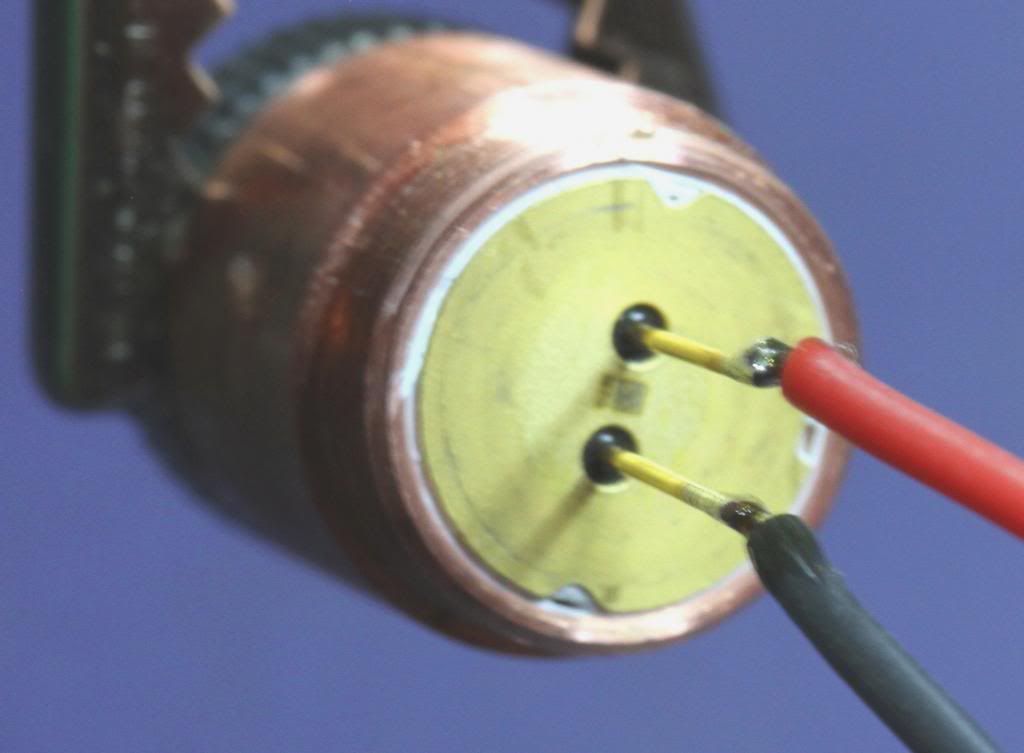

Solder some temp wires to my diode

Slide a little heatshrink over just to make sure nothing bad happens, I'm not going to heat it. It's coming right back off.

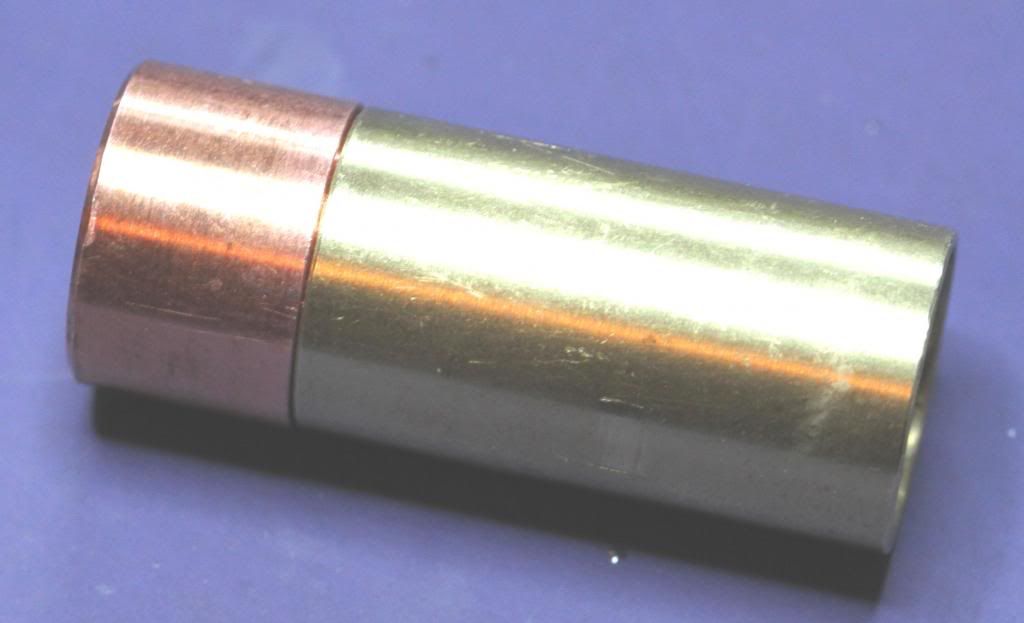

Put the back half on, take out the plastic lens and replace with a real lens, I just grab a G-2 and stick in it. Put the module in a heatsink.

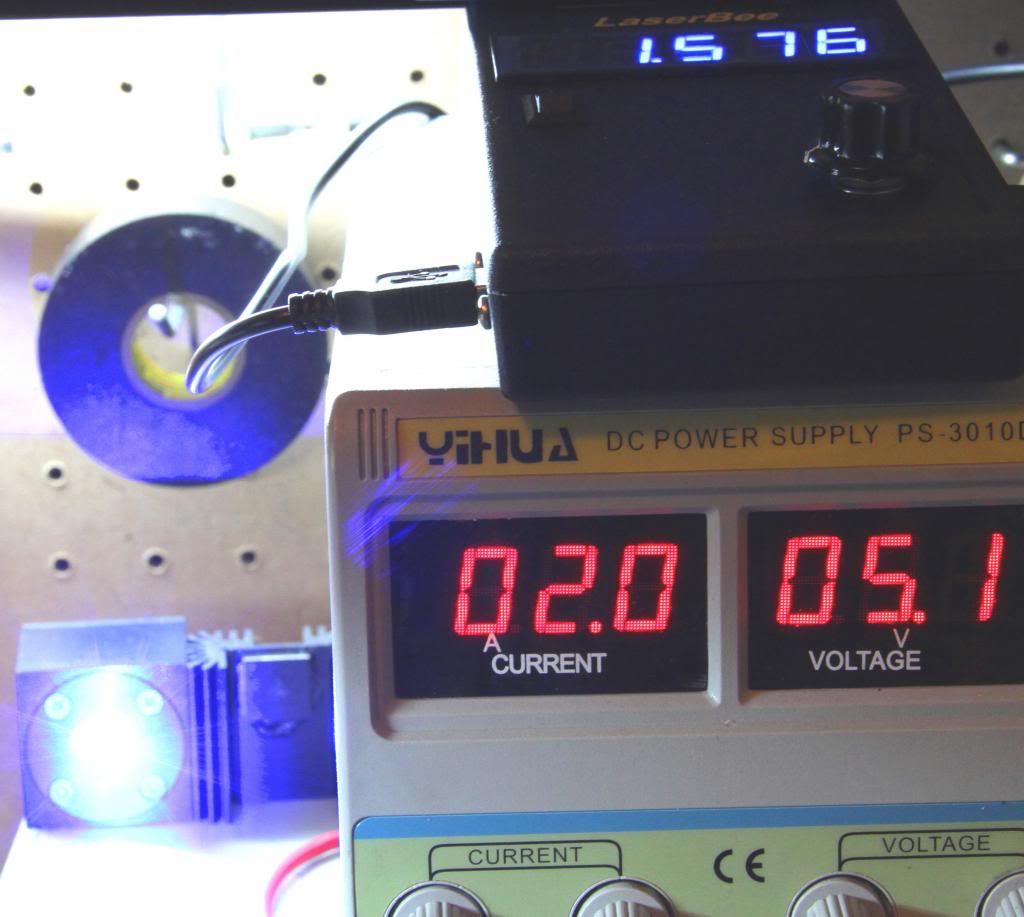

Now comes the fun part ! Smoke 'em if ya got 'em !

I slowly start increasing the current and watch my LPM, when the diode hits a plateau and stops gaining in relation to current. I stop. It doesn't really matter what the lpm reading is. It is what it is. When it slows down gaining that is what the current gets set at. I haven't blown a diode since I started doing it like that. Knock on wood. Watch, the next one will pop. Diode Gods are fickle.

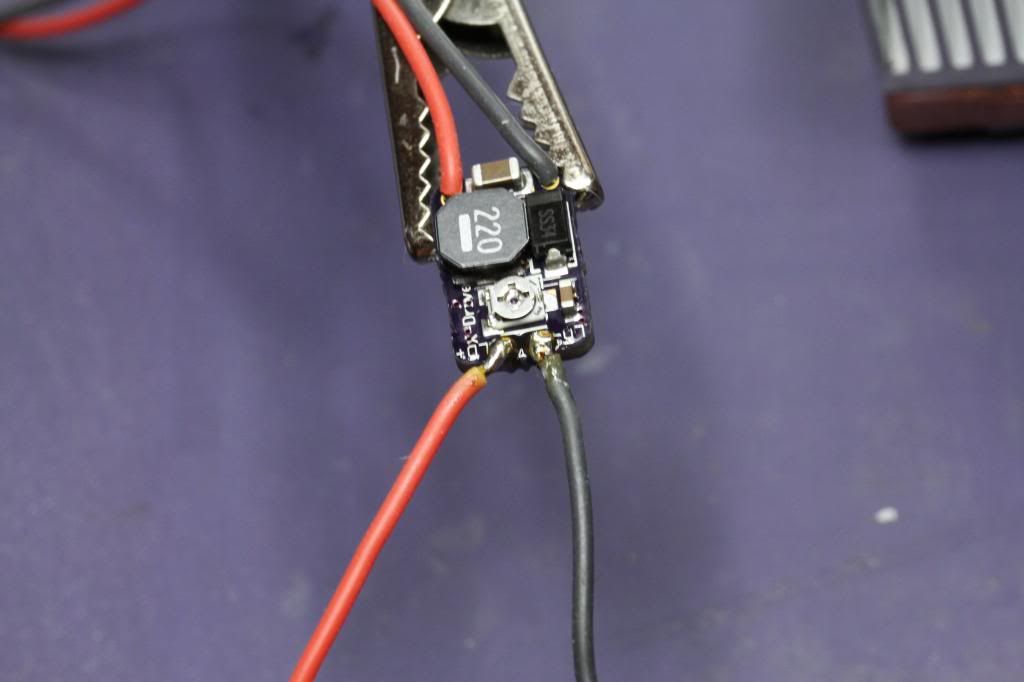

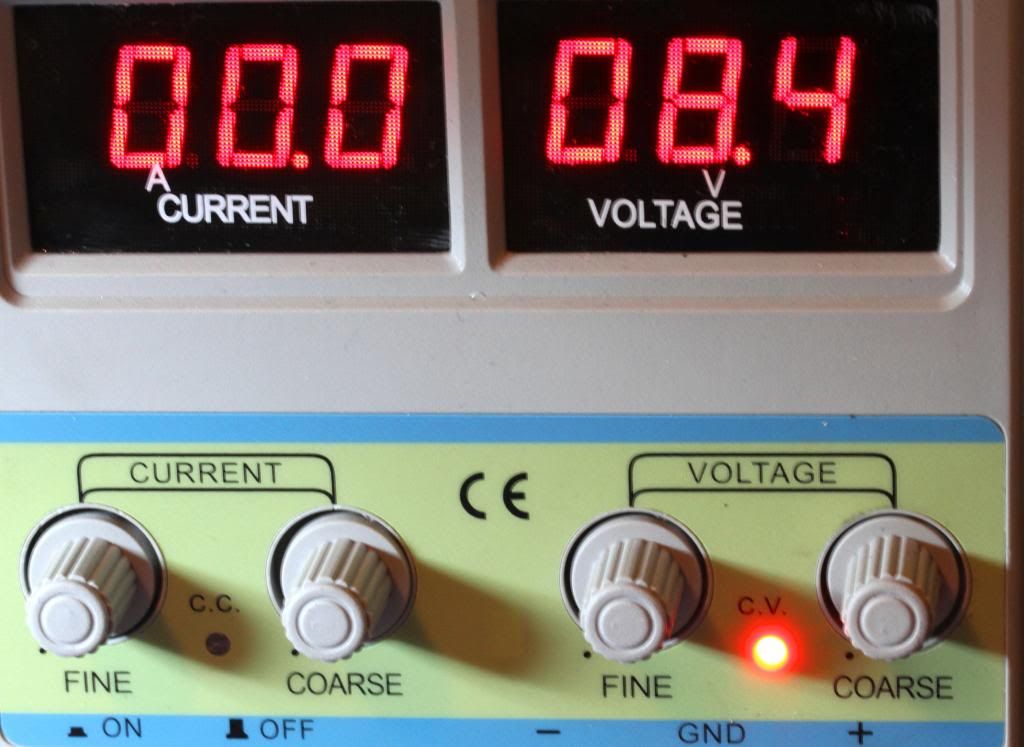

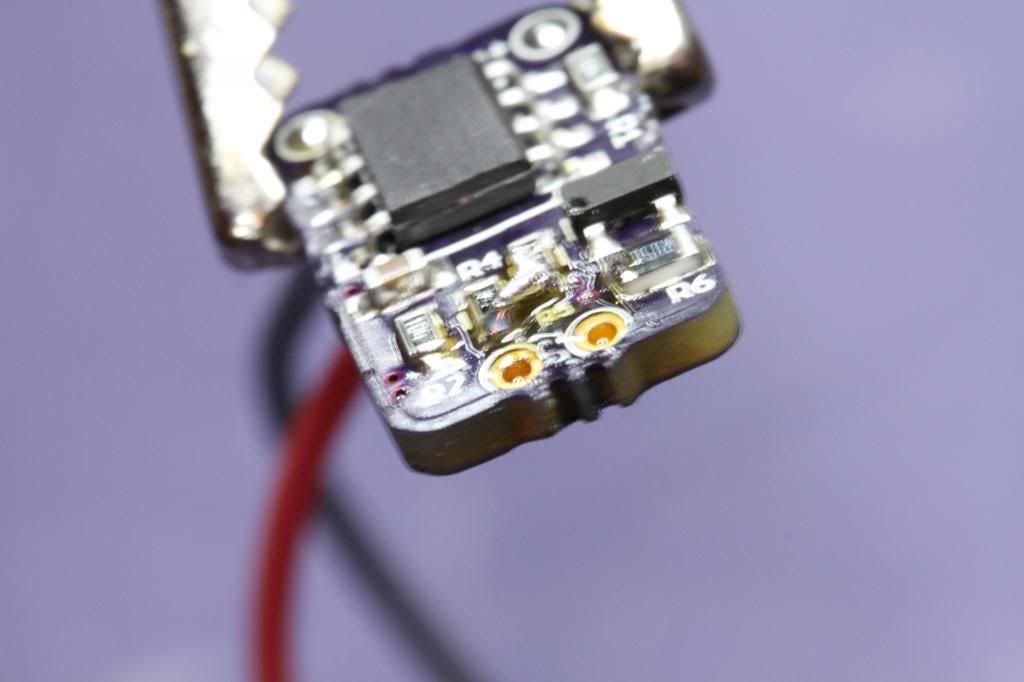

Now I can solder up my drive and set current

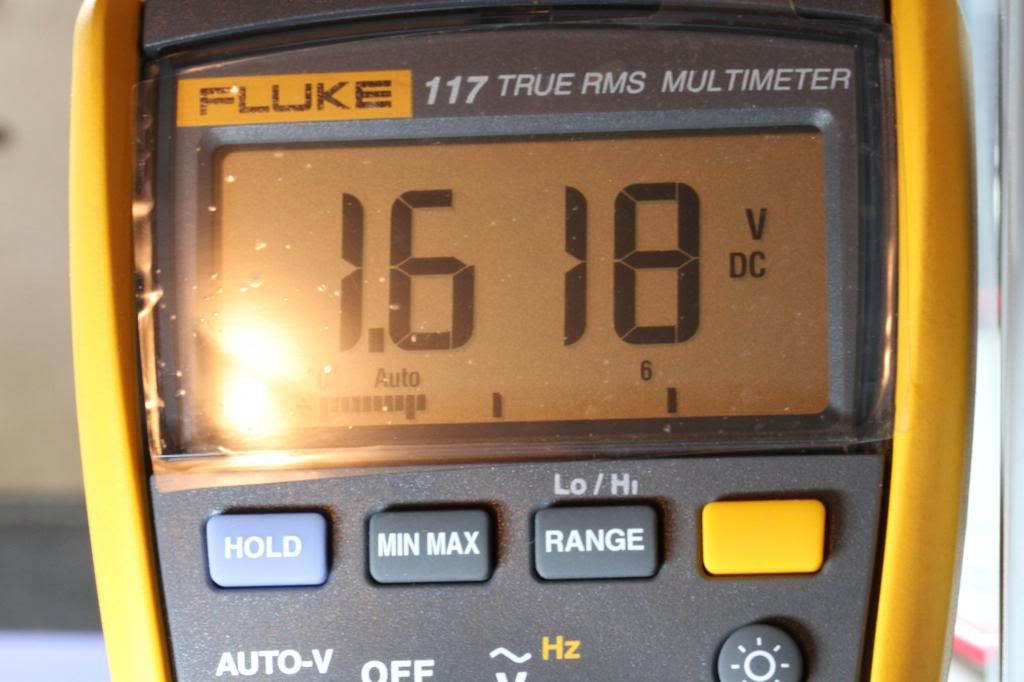

I'm using an Xdrive so I set my voltage to the most it will see.

and use my test load and Fluke meter to set it.

WTF ! It's a 3 amp drive ! I'm only getting 1.6a !:yabbmad:

Oh yeah, the blob. I forgot the blob. I hate the blob. I'm no good at the blob

It's a blob. That's about all I can say for it.

Success ! The blob works ! There's my two amps ! This thing might actually work !

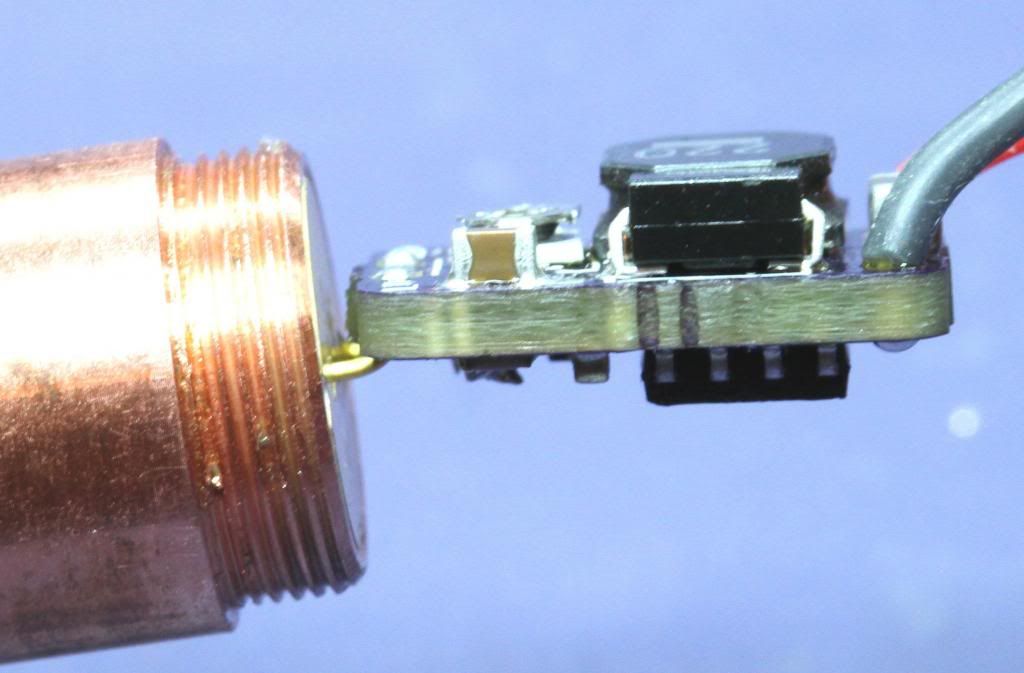

Marry my drive and my diode. Aren't they a cute couple ! They were made for each other !

It's their wedding night, better wrap that rascal for protection !

I put a little thermal paste on the threads. Just a little dab will do ya.

Well look what the postman brought me. A host from Mrcrouse

Down the rabbit hole it goes !

It works ! Sweet Mother of Photons ! Thank you Laser Gods for showing mercy on this soul !

I'm going to try and get some outside shots of it tonight. See if I can capture the actual color

Thanks for looking !