RB astro

0

- Joined

- Apr 6, 2014

- Messages

- 2,436

- Points

- 113

Tutorial - How to clean & 'varnish' a Copper Host for a permanent beautiful finish.

Here's a step by step tut on cleaning and varnishing copper hosts for a beautiful permanent shiny finish.

You'll need:

Next add two heaped table spoons of table salt into a bowl deep enough for the hosts to sit in. (I used Kirkland's pink Himalayan Salt from Costco, yes we have Costco here too :yh .

.

Add the vinegar to the bowl making sure there's enough to fully submerse and cover the hosts.

Stir the vinegar and salt well till it dissolves properly.

Then place your hosts in the solution.

Keep stirring and agitating to solution, rotating the hosts every so often to get an even exposure on all surfaces of the hosts.

Leave the hosts in the solution for a period of between 5 to 15 minutes depending on how much tarnish there's on the copper.

I left mine in there for 10 minutes.

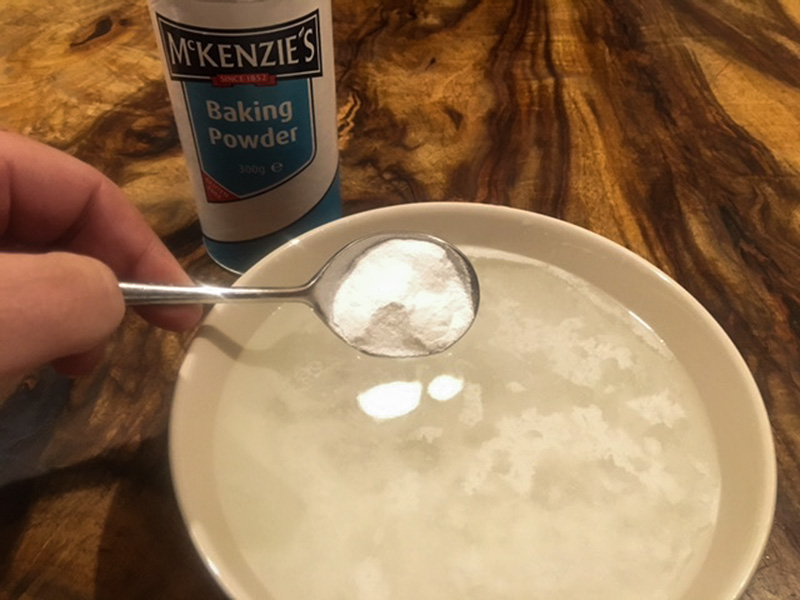

While the hosts are in the vinegar solution, prepare the baking power solution in another bowl.

The baking powder solution is used to stop the acidic reaction on the copper once you take out the hosts from the vinegar solution.

Add two heaped table spoons of baking powder into some luke warm water in a separate bowl and mix thoroughly.

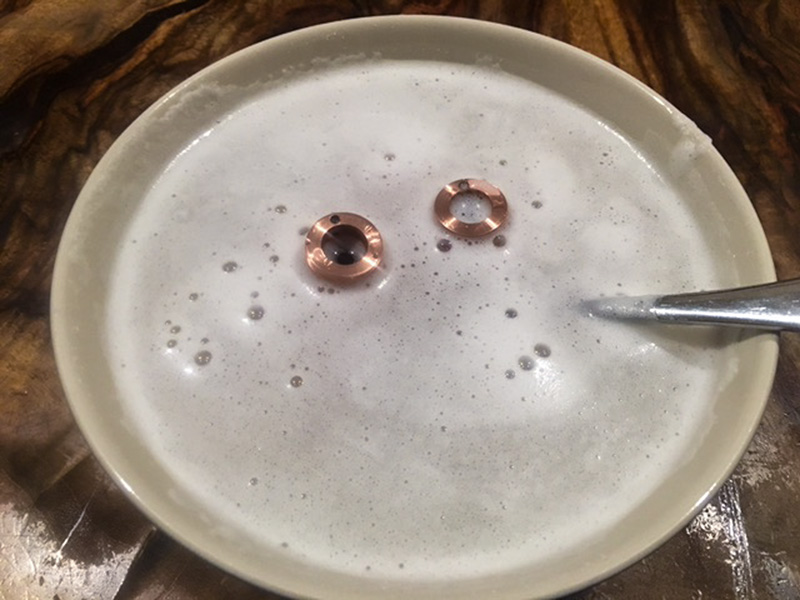

Take out the hosts from the vinegar solution once the time expires and quickly rinse off in cold running water then place them directly into the prepared baking powder solution and leave in there for 2 minutes.

Once that's done rinse off the hosts once again under running water and thoroughly dry the hosts.

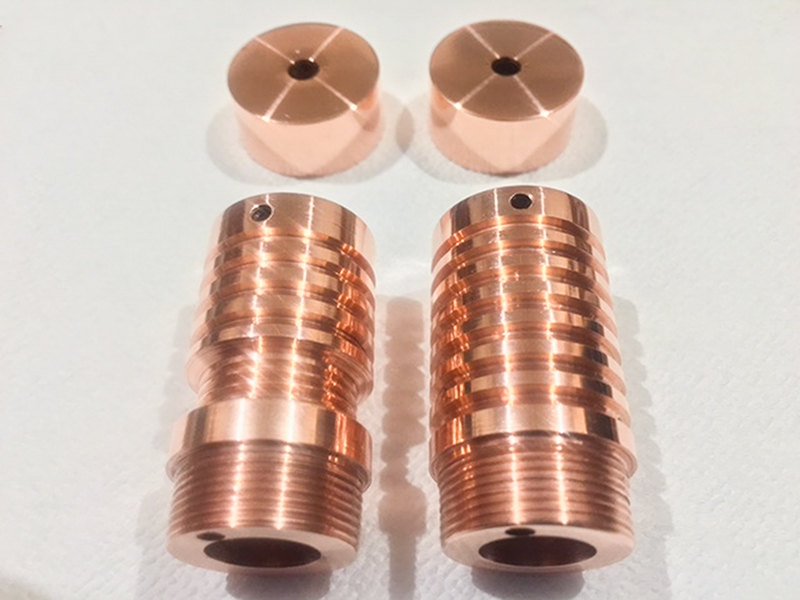

The result is a nice new shiny host ready for varnishing, a big difference from the start.

Now prepare your hosts for varnishing.

I taped the threads so that I don't get any varnish on them.

Also I place toothpicks in the grommet holes to stop any varnish entering in and to make it easier to handle the hosts once they're varnished.

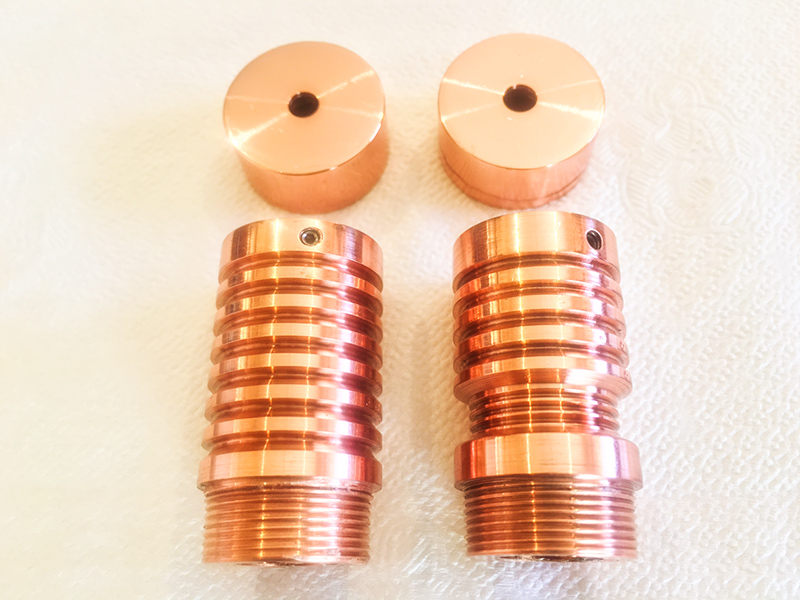

Now I wanted to try both the Rust-olium Clear Gloss (thanks for the heads-up on this one Billy - badboybilly) and the PCB Lacquer to see which one works best.

I used the Rust-olium on the 'Deep Groved' Copper host from Rich and the PCB Lacquer on the 'Even Grooved' Copper host again from Rich.

I found that both gave excellent results.

The only difference was that the PCB Lacquer dried in half the time, around 10 minutes compared to the Rust-olium which took 20 minutes.

I left them to dry overnight.

The results were identical in the end so it's up to you to choose which one you'd prefer to use.

And finally, the result, ready to build.

Stunning !!

Hope you enjoyed and found this tutorial helpful.

RB

:beer:

Here's a step by step tut on cleaning and varnishing copper hosts for a beautiful permanent shiny finish.

You'll need:

- White Vinegar

- Table Salt - two table spoons full

- Baking Powder - two table spoons full

- Two glass bowls

- Luke warm water

- Clear Gloss or PCB Lacquer in a can

Next add two heaped table spoons of table salt into a bowl deep enough for the hosts to sit in. (I used Kirkland's pink Himalayan Salt from Costco, yes we have Costco here too :yh

Add the vinegar to the bowl making sure there's enough to fully submerse and cover the hosts.

Stir the vinegar and salt well till it dissolves properly.

Then place your hosts in the solution.

Keep stirring and agitating to solution, rotating the hosts every so often to get an even exposure on all surfaces of the hosts.

Leave the hosts in the solution for a period of between 5 to 15 minutes depending on how much tarnish there's on the copper.

I left mine in there for 10 minutes.

While the hosts are in the vinegar solution, prepare the baking power solution in another bowl.

The baking powder solution is used to stop the acidic reaction on the copper once you take out the hosts from the vinegar solution.

Add two heaped table spoons of baking powder into some luke warm water in a separate bowl and mix thoroughly.

Take out the hosts from the vinegar solution once the time expires and quickly rinse off in cold running water then place them directly into the prepared baking powder solution and leave in there for 2 minutes.

Once that's done rinse off the hosts once again under running water and thoroughly dry the hosts.

The result is a nice new shiny host ready for varnishing, a big difference from the start.

Now prepare your hosts for varnishing.

I taped the threads so that I don't get any varnish on them.

Also I place toothpicks in the grommet holes to stop any varnish entering in and to make it easier to handle the hosts once they're varnished.

Now I wanted to try both the Rust-olium Clear Gloss (thanks for the heads-up on this one Billy - badboybilly) and the PCB Lacquer to see which one works best.

I used the Rust-olium on the 'Deep Groved' Copper host from Rich and the PCB Lacquer on the 'Even Grooved' Copper host again from Rich.

I found that both gave excellent results.

The only difference was that the PCB Lacquer dried in half the time, around 10 minutes compared to the Rust-olium which took 20 minutes.

I left them to dry overnight.

The results were identical in the end so it's up to you to choose which one you'd prefer to use.

And finally, the result, ready to build.

Stunning !!

Hope you enjoyed and found this tutorial helpful.

RB

:beer: