Welcome to Laser Pointer Forums - discuss green laser pointers, blue laser pointers, and all types of lasers

How to Register on LPF | LPF Donations

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WTB: High Power 40 watts Laser System

- Thread starter LiveRock

- Start date

diachi

0

- Joined

- Feb 22, 2008

- Messages

- 9,700

- Points

- 113

Krutz

0

- Joined

- Nov 21, 2007

- Messages

- 1,733

- Points

- 48

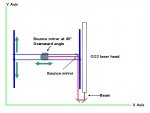

nice diagram! superior to my "move the fabric" for sure!

perhaps divergence in such a long wavelength and thus the "large" spotsize could be a factor..?

manuel

perhaps divergence in such a long wavelength and thus the "large" spotsize could be a factor..?

manuel

diachi

0

- Joined

- Feb 22, 2008

- Messages

- 9,700

- Points

- 113

nice diagram! superior to my "move the fabric" for sure!

perhaps divergence in such a long wavelength and thus the "large" spotsize could be a factor..?

manuel

Thanks!

Yeah I considered the divergence , if you look at my original post I said there would be a focusing lens after the last bounce mirror ( or second mirror in that post , but that was meant to be the last mirror

Regards,

Adam

Krutz

0

- Joined

- Nov 21, 2007

- Messages

- 1,733

- Points

- 48

yes, i saw you mentioning the ZnSe lens, Adam!

my idea was about the bad divergence of co2 altogether. i read because of the high wavelength of 10600nm it wouldnt be possible to install a co2 tube as a sentry gun for example. the beam would diverge so fast, there would be no powerdensity left after the few meters from the roof to the ground.

if the xy-cutting-table would be 2x2m, which could be the minimum for such an expensive setup, the total beampath would be 4 meters worst case. sure, lots of power would help, but perhaps he would be cutting with a 2cm-point by then!

hmm, i have to read up about the wavelength-dependent collimation and focusing.. ever since the idea back then to run both the red and 405nm off a ps3 diode..

manuel

my idea was about the bad divergence of co2 altogether. i read because of the high wavelength of 10600nm it wouldnt be possible to install a co2 tube as a sentry gun for example. the beam would diverge so fast, there would be no powerdensity left after the few meters from the roof to the ground.

if the xy-cutting-table would be 2x2m, which could be the minimum for such an expensive setup, the total beampath would be 4 meters worst case. sure, lots of power would help, but perhaps he would be cutting with a 2cm-point by then!

hmm, i have to read up about the wavelength-dependent collimation and focusing.. ever since the idea back then to run both the red and 405nm off a ps3 diode..

manuel

GooeyGus

0

- Joined

- Mar 8, 2008

- Messages

- 2,669

- Points

- 48

A diode system for this application is probably the WORST idea.

No offense or anything, Blue, but a diode would suck for this.

He's talking about a cotton-like material, probably white, you would need RIDICULOUS amounts of power to cut through white fluffy fabric with any sort of speed. At least 100W, and it still probably wouldn't be really fast.

With CO2, even just 20W would cut through it like it wasn't even there. Not to mention CO2 is much more safe for the eyes, and adding in a HeNe aiming beam is very easy if visibility is an issue.

Specialized and expensive cooling?! lol.... A tiny radiator and an equally tiny pump with a bucket of water is all you need. Keep in mind, a diode with any sort of power would have these same cooling requirements. Yes, you could TE cool it, but it would still need a huge (and probably water cooled) heat sink. But, usually the high power diodes have water jakets built in, in which case you would need the same cooling setup as the CO2 tube.

Diodes are very good at cutting very few specific materials. CO2 lasers will cut pretty much anything. They are far more diverse, and in my opinion easier to work with.

In most professional shops, they have large CO2 cutting systems because they can cut a very wide range of materials. Only in specialized settings, where the shop is cutting a lot of one material, will you see a large scale diode setup. Every machine shop I've ever been to uses either q-switched YAG or CO2.

No offense or anything, Blue, but a diode would suck for this.

He's talking about a cotton-like material, probably white, you would need RIDICULOUS amounts of power to cut through white fluffy fabric with any sort of speed. At least 100W, and it still probably wouldn't be really fast.

With CO2, even just 20W would cut through it like it wasn't even there. Not to mention CO2 is much more safe for the eyes, and adding in a HeNe aiming beam is very easy if visibility is an issue.

Specialized and expensive cooling?! lol.... A tiny radiator and an equally tiny pump with a bucket of water is all you need. Keep in mind, a diode with any sort of power would have these same cooling requirements. Yes, you could TE cool it, but it would still need a huge (and probably water cooled) heat sink. But, usually the high power diodes have water jakets built in, in which case you would need the same cooling setup as the CO2 tube.

Diodes are very good at cutting very few specific materials. CO2 lasers will cut pretty much anything. They are far more diverse, and in my opinion easier to work with.

In most professional shops, they have large CO2 cutting systems because they can cut a very wide range of materials. Only in specialized settings, where the shop is cutting a lot of one material, will you see a large scale diode setup. Every machine shop I've ever been to uses either q-switched YAG or CO2.

HIMNL9

0

- Joined

- May 26, 2009

- Messages

- 5,318

- Points

- 0

If you're planning to build a cut table for fabric for models (clothes, etc), and plan to use a CO2 fixed laser with beam redirectors, don't forget a decent air flow systems on the mirrors (preferably from the laser, filtered), and the same for the moving mirrors, and also a decent vacuum system (aspiration for the dust) on all the machine.

Dust and cotton residuals on the mirrors can interfer with the beam and cause problems ..... and, also, cotton dust in suspension in the air, over a certain level, acts as an explosive (yes, same as flour), and also if not this danger, cotton dust accumulate in some place is worse than a fuse, in certain conditions (enough a spark for start a slow combustion, that continue also in background or inside machine spaces)

BTW, do you want to build a system for small parts, or an industrial line ? (some industrial fabric cutting tables i've seen was 2 x 6 meters or more, cutting space)

Dust and cotton residuals on the mirrors can interfer with the beam and cause problems ..... and, also, cotton dust in suspension in the air, over a certain level, acts as an explosive (yes, same as flour), and also if not this danger, cotton dust accumulate in some place is worse than a fuse, in certain conditions (enough a spark for start a slow combustion, that continue also in background or inside machine spaces)

BTW, do you want to build a system for small parts, or an industrial line ? (some industrial fabric cutting tables i've seen was 2 x 6 meters or more, cutting space)

- Joined

- Dec 29, 2007

- Messages

- 112

- Points

- 0

Do not purchase anything from blue fusion

he is a know scam artist!

he is a know scam artist!

- Joined

- Feb 22, 2008

- Messages

- 3,187

- Points

- 48

Do not purchase anything from blue fusion

he is a know scam artist!

why isn't he perma banned yet ?????

Cold????????????????