Really I cant remember in what order I had issues with the lava drives, but they were not all being tested at the time the issues began that was the woopdrive. You had also mentioned something of length of wire to the drivers input and out to the LD. I set all of the drivers to 180ma, and powered them with 3.6v lithiums assembled and working in a host.

On the first handheld to fail, turned out the diode was okay and the driver was not. Another was the original lavadrive kits, twice the size as the ones we know now. That one was fine until I moved the laser into another host using 3 1.5v AAA's instead of a single 3.6v, all I heard was a high pitch squeel and that was it, no more nothing.

Im not sure with that one because it was assembled by me, and there is room for error on my end. And the last one to go was in a DX greenie pointer case, I was using it many hours per week, and when its time came, flicker of death as you put it, and both the diode and driver no longer worked With that one, the diode could have failed followed by the driver, not sure. I have another that still works fine, just no soft start anymore. :-?

Now im nowhere near as fluent in electronics as some on this site, but honestly I never put much thought into the details of why, rather than how to do my own ;D.

What I dont understand is why all of a sudden you change your mind on the benefits on this arrangement, where you had me sold on how good it was. I didnt go this route with the idea of it being better, but chose to go through the fun of making my own, and of course to avoid the additional costs

As for others having the same problems, maybe some members who drive their 405s higher than 180ma could share their experiances? I know there are others who like to push the envelope as well, but as you said, may feel the failures came from the high current.

All I know, is as far as this driver goes, all the higher efficiency diodes that I set to 180ma (give or take the tolerance factor) are alive and kicking, putting out a more stable mW than any of my 405's using an LM317. Everytime I test them, I graph them and compare the charts, and see a consistent flat line at the top of the graph with very little wandering and a nice stable output.

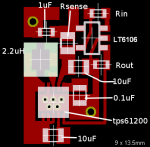

Apples and oranges I guess, and for the filtering I changed the cap to a 100uf across the LD, but have to get it tested on a scope. My original layout had 30uf total on the out and only came in at 10mV ripple, and did not summon alien beings

I have changed the layout to include additional polarity protection and some other items suggested by IgorT. I will keep making the changes until I get this perfect, or as close as possible. :

yag-222 said:

Lol !! Hey rkcstr, was not claiming that nobody on this forum know the FlexDrive, I just saw it was not mentioned in last posts... I think every body here know his fantastic work...

Hello wannaburn, world is very litle... Nice to meet you on this forum, thanks for the explanations about the reliability of drLava driver for 803Ts, it support the choice I make for your driver. FlexDrive will be usefull as soon as I can found one of these 6x diodes. Your experiment with your driver reliability is very interesting too and... 185mW !! Impressive with the use you make of them.

Thanks for your support...

John

I wondered why that name looked familiar :

Good to see you on the forum,

lots of info for all and a great place to try some new things. The 6x diodes are

currently quite expensive, but the price is dropping, around 250. average for now.

It is a definate worth while project if you can shake the nerves of getting the diode out ;D

Hope to see your projects in the future, everyone hear loves a good beamshot and lots and lots of pics.

@IgorT below

Sales pitch? Ahhh, last time I checked, you were the one pedalling your wares on this forum, not me. But if that makes you feel better about it all, than enjoy [smiley=thumbsup.gif] I dont link to my sales, and come here to discuss LASERS, not how much I want for my sh!t.