IgorT

0

- Joined

- Oct 24, 2007

- Messages

- 4,177

- Points

- 0

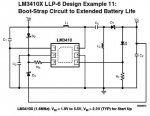

Well, this is the one i did.. Needs some finishing touches, but it should be ok..

Now i just need to compare sizes.... How big is yours?

H-S is supposed to be the area for mounting a HeatSink. I also made some notches into larger planes, to make it more obvious, where the connections are supposed to be.. The notches are only two pixels deep, so they shouldn't impair anything..

The only thing it lacks is the FeedBack line, because i wanted to draw it on the upper plane.. Better add some markings, where it's supposed to be..

Finally, etching can begin...

EDIT: This is the finished version.. What do you think?

Ups, i forgot to add some exposed "dogbone" to the right of the IC...

Now i just need to compare sizes.... How big is yours?

H-S is supposed to be the area for mounting a HeatSink. I also made some notches into larger planes, to make it more obvious, where the connections are supposed to be.. The notches are only two pixels deep, so they shouldn't impair anything..

The only thing it lacks is the FeedBack line, because i wanted to draw it on the upper plane.. Better add some markings, where it's supposed to be..

Finally, etching can begin...

EDIT: This is the finished version.. What do you think?

Ups, i forgot to add some exposed "dogbone" to the right of the IC...