Found some pp sheets 1/4 inch thick on the bay. Good price and size. May get a couple and use that for my rsg. Couple questions though.

When screw get the pp together in the spark gap area can I use metal screws? Or is there some other method I should use to secure cut pieces together.

How do I build HV terminals? It would be neat to have two nst style terminals back on the back so I can just bolt on either the coil or whatever I want to fry. I see some on the bay but if they can be made cheaper I'llgo that route .

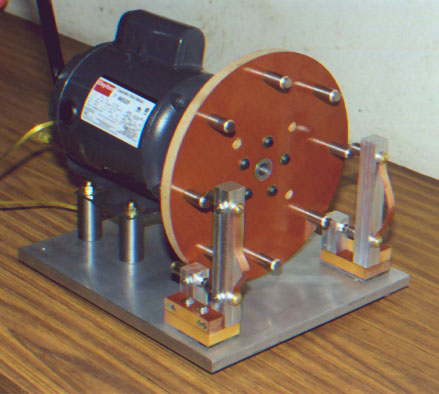

1) I'd be not using PP or PE anywhere around your RSG, as PP will easily succumb to heating (burns rather like wax). Building an RSG requires VERY a very thick base/ heavy due to the vibrations and (kick) made by the motor. You're going to want to look at Phenolic for your RSG (disk) and Oak ( or something with mass) for your base. Phenolic ain't cheap either.

2) The electrodes on your disk can be made from copper but the contact points should be made from large dia WZr welding (cutting) electrodes. You must make sure these have a (non radioactive symbol on them). Avoid Thoridated electrodes.

3) You must always make sure that the electrodes on the disk are secured with some sort of dual lock nut... The disk will be spinning at 2-300Km/hr (3600RPM) and the last think you want is flying electrode bullets!! If these hit you, they can seriously injure or kill you or someone else.

I used a double lock nut on mine.

4) You must make sure your RSG motor can handle a heavy shaft load.

I've posted a few pics to show you some set ups.. .you'll notice that most are using metal bases (floor plates)

you'll notice below the RSG is using many contact points.... This is an example of a Synchronous RSG. These motors are rare, or they have been modified to

be in sync as the supply current. These are ideal but not completely necessary.

This is a basic setup using an cheap angle grinder.

This is an Asynchronous setup using 4 precisely spaced electrodes.

I have done business with Greg in the past while building my last big coil.

I do not recommend using brass for your electrodes as they will burn down quickly despite Greg's experience at 10KRPM. I'd seriously consider

a heavy base. Vibrations from angle grinders can throw the electrodes out of alignment. So a heavy base will dampen this effect.

There are pros and cons of using Asynchronous and Synchronous motors

in an RSG.

- Synchronous rotary gap

1) Firing rate is fixed at the design stage

2) The system should be designed to be optimal at the synchronous firing

3) Requires an induction motor to be modified for salient pole, synchronous rate

4) Requires firing phase to be carefully set for correct operation

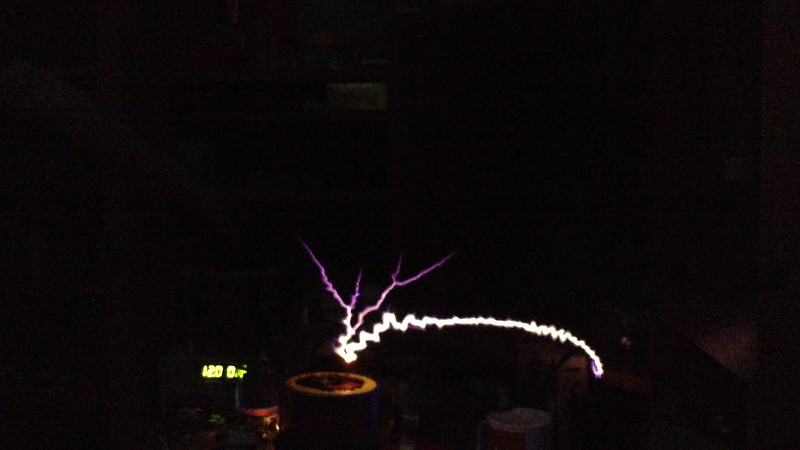

5) Produces more consistent, slow methodical evolving sparks

6) Good power throughput with large ballast inductance.

7) Peak voltage stays constant because resonant rise is kept under control

(ok for multiple NSTs banks!!)

8) No beating because operation is synchronous with the supply frequency

9) Ideal for analysis and taking measurements

- Asynchronous rotary gap

1) A wide range of firing rates are possible for flexibility during experimentation

2) The optimal operating point of the system can be found by varying the firing rate

3) Easy to build, can use any general purpose AC or DC motor (including angle grinders!! hint)

4) No special set-up is required

5) Produces frantic spark action, with frequent long sparks (emphasis on erratic!!)

6) Requires low ballast inductance, particularly at high speed. (This implies higher fault currents.)

7) Can cause damaging resonant rise in charging circuit, (particularly at speeds below 200bps. Stay above 200BPS) (Don't use this for NSTs or you'll kill them!)

8) Can give surging/beating problems below 200bps

9)Rotary speed can be used to control power throughput in DC powered systems (N/A in your situation)

This information was taken from

Rotary spark gap overview

and I added a little to it.

My personal experience with RSGs has been variable. Heavy bases are HIGHLY recommended due to motor vibration.

Brass does not work well for electrodes.. WZr is the best material.

Keep your RSG away from your coil until you've got it working. Last thing you want is a flying electrode to damage your tank cap or secondary!!

Hope this info helps you!!

IMG_0428[1] by TwirlyWhirly555, on Flickr

IMG_0428[1] by TwirlyWhirly555, on Flickr

IMG_0452 248 by TwirlyWhirly555, on Flickr

IMG_0452 248 by TwirlyWhirly555, on Flickr IMG_0457 221 by TwirlyWhirly555, on Flickr

IMG_0457 221 by TwirlyWhirly555, on Flickr IMG_0454 by TwirlyWhirly555, on Flickr

IMG_0454 by TwirlyWhirly555, on Flickr