- Joined

- Sep 20, 2013

- Messages

- 20,284

- Points

- 113

You wouldn't happen to know what their average capacity is do you?

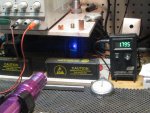

Brand new coming from liionwholesale.com they averaged 3300 mAh. I have tested every one I ever got as I received them. Panasonic also made 3400 mAh cells too. They all tested over that capacity too.

![20191008_165620_HDR[1].jpg 20191008_165620_HDR[1].jpg](https://laserpointerforums.com/data/attachments/49/49810-32b110f262ea4e1c8d6fec063732c779.jpg?hash=MrEQ8mLqTh)

![20191008_165708_HDR[1].jpg 20191008_165708_HDR[1].jpg](https://laserpointerforums.com/data/attachments/49/49811-9f31767220761f8e35a46ac957ad6ab1.jpg?hash=nzF2ciB2H4)

![20191008_165651_HDR[1].jpg 20191008_165651_HDR[1].jpg](https://laserpointerforums.com/data/attachments/49/49812-0b2d70a6d4ec63d26c362f7dbbea3c46.jpg?hash=Cy1wptTsY9)