absolute

0

- Joined

- Jan 5, 2016

- Messages

- 53

- Points

- 18

Alright guys,

Here it is. Nichia VS Osram. (Nichia NUBM31T 95W VS Osram PLPM4 450 - 60W)

WOW that is some pretty good alignment for such an array.. the Nichia one I mean. Thanks for showing this

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Alright guys,

Here it is. Nichia VS Osram. (Nichia NUBM31T 95W VS Osram PLPM4 450 - 60W)

I was able to get the nubm31t to focus to about (1.2 x 1.8 mm) spot with a Plano Convex lens 200mm FL

It is hilarious to instantaneously explode things I put into the focused beam.

Alright guys,

Here it is. Nichia VS Osram. (Nichia NUBM31T 95W VS Osram PLPM4 450 - 60W)

This is my first time doing a beam test. I did what I wanted to do.

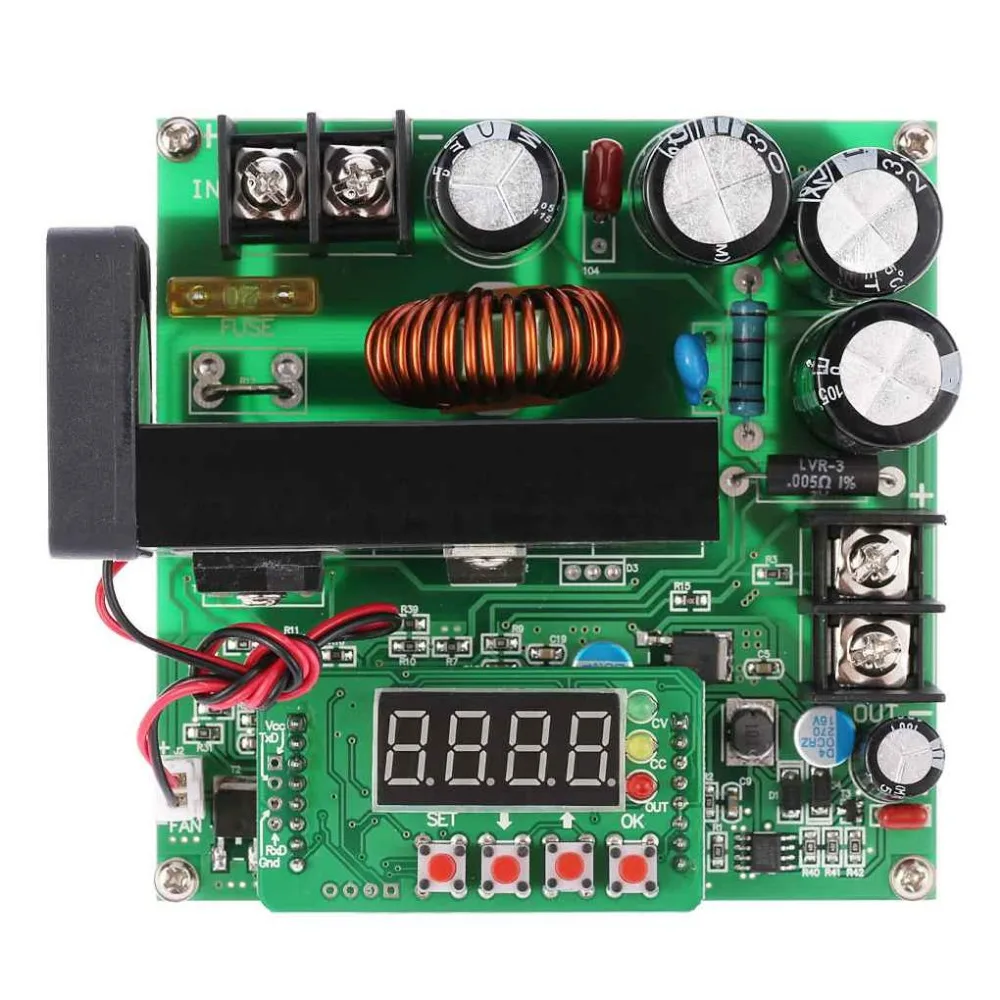

Driver used: MDP-XP w/ 4 modules

Note: Nichia = made in Japan, Osram = made in China.

Driver for nubm31t?I am not sure. This is what I can calculate for you:

Nichia nubm31t 95W @ 1.8 x 1.2mm = 44W/mm2 power density

Nichia nubm44v2 7W @ 0.2 x 0.2mm = 175W/mm2 power density

The nubm44v2 has much more power density. But 9% of the output of the nubm31t. Need to consider what you plan to cut. If you need clean and precise cutting, seems like nubm44v2 is still the best.

However, maybe things like metal or stone needs raw output, this may do the job?

There is a way to farther reduce the spot size. You need to modify the multi lens and slightly increase the height and farther away from the diodes.

If you are interested to test this, I can refer you to a laser seller with a suitable driver for 50USD (new) and could sell you my osram plpm4 450 for cheap lol

Driver for nubm31t?

Driver for nubm31t?