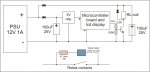

Uhm ..... i see something strange, in the circuit, but more than errors, it can be drawing mistakes .....

First, the reset pin of the ATmega, is active low ? (means, you must put it low for reset ?) ..... if yes, R1 as 10kohm, and an 1uf capacitor between this pin and the ground, ensure you an automatic reset each time you power up the system ..... also, no bounce filters, on the two buttons ? ..... is always better place an RC also there, for take care about disturbs and bounces .....

The mosfet that drive the relay ..... is really connected in that way ? ..... no resistor on the led, and the mosfet connected directly to the atmega output pin ? ..... and the LM335 seem reversed, but this can be just a drawing error ..... just impressions, anyway.

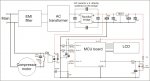

Can you try to wire all in this way, if you want ? .....

The tracks in bold, means using wires of big section (size), and the GND line is better if is more "robust" of all the rest, too ..... the diodes can be 1N400X serie ..... the LM336 is better wired in this way, so you can adjust it more precisely (and also it cannot become overstressed from current, cause the maximum current that it can hold in safe range, is only 5mA) ..... the EMI filter can be took from any old PC PSU, if you don't want to wind manually the double-wires coil ..... also (but this depend from the relay coil resistance), a resistor can be added in serie from the coil to the positive ..... 22 ohm 2W can be good, but i need to know the coil resistance, for be sure ..... and don't connect the led to the gate, it cause problems ..... connect it in parallel to the coil, with its own resistor .....

Can post externally a bigger version, if the schematic is not too clear at this resolution (VB size limit, here) ..... and, i have not redrawn all the ATmega connections, sorry but it's a damn pain you-know-where, to draw electronic schematics with coreldraw

EDIT: also, the 4 capacitors on the bridge, is not indispensable to solder them directly to the bridge pins, just nearest possible them