- Joined

- Jul 10, 2015

- Messages

- 13,090

- Points

- 113

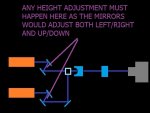

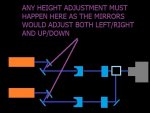

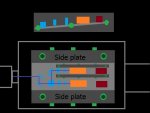

The center would be fixed and all 3 on the same plane, that would be adjusted and set, only the horizontal convergence would be controlled by the servo/mirrors for the outer 2 or 4 if a 5 beamer. Yes outer most in a 5 beam would be a different ratio.

The longer the arm attached to the articulated mirror the shorter the mirrors range but the finer the control and I am only looking to play at 10 meters or so, the 6X corrected with 3.3XBE will reach out further and project a spot better in the far field, this converged concept is just a short range burner although if using ndb7875's could reach 25 meters pretty well if using 2X or 3X c-lens pairs.

The longer the arm attached to the articulated mirror the shorter the mirrors range but the finer the control and I am only looking to play at 10 meters or so, the 6X corrected with 3.3XBE will reach out further and project a spot better in the far field, this converged concept is just a short range burner although if using ndb7875's could reach 25 meters pretty well if using 2X or 3X c-lens pairs.

Last edited: