- Joined

- Nov 2, 2012

- Messages

- 632

- Points

- 43

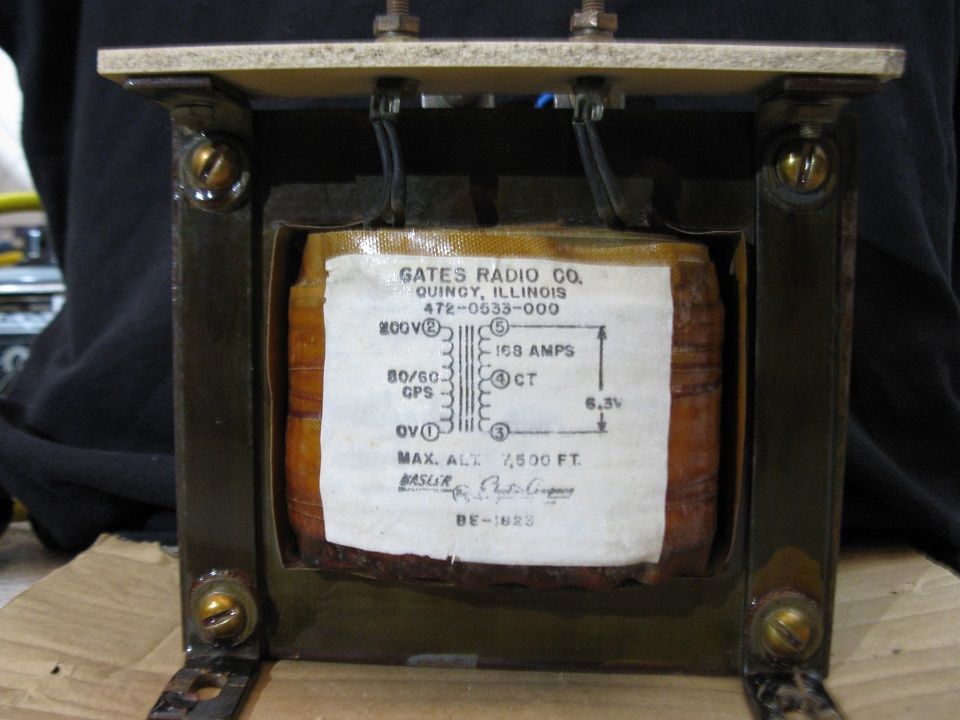

I bought a Basler Electric B-1823 transformer on Ebay and it arrived Fed Ex over the weekend. Seems to be the heater transformer for large RF vacuum tubes. According to the seller, it came out of a 20kW Gates radio set.

It's 1kVA, rated output is 6.3V and 168A. Input is 200V, should be ~5A at rated power. For now I'm limited to 140V maximum input. This transformer is no joke. At just 1.5V, shorting a 12 AWG copper wire across it makes the wire instantly hot. At 2.5V the wire is glowing orange hot after one second, and melting after two.

I think if I managed to kill it, it would be the primary giving out. It looks like 16AWG. I'm pretty sure it's actually a dual primary as each of the power pins has two wires going to different places. The 200V input is odd, but apparently tube radios like this used a 200V supply for their B+. Since it's rated to handle 200V at 50Hz, I wonder if it would be OK to give it 220, 230, maybe even 240 volts if the line is guaranteed to be 60Hz.

The secondary is built of 4 square-section "strands" in parallel, there are at most 6 or 7 turns of it in a single layer. It's center tapped, but the tap wire is only one strand. Maybe the radio used some tubes with a 3-volt heater as well as 6.3 volts. It's rated for 168A continuous. That's a lot of amps.

Plenty of 1kVA transformers online but they're mostly 120/240/480 control transformers. I thought this one was pretty interesting since it's 1kVA at very low volts. Little risk of electrocution but definitely a fire hazard!

It's 1kVA, rated output is 6.3V and 168A. Input is 200V, should be ~5A at rated power. For now I'm limited to 140V maximum input. This transformer is no joke. At just 1.5V, shorting a 12 AWG copper wire across it makes the wire instantly hot. At 2.5V the wire is glowing orange hot after one second, and melting after two.

I think if I managed to kill it, it would be the primary giving out. It looks like 16AWG. I'm pretty sure it's actually a dual primary as each of the power pins has two wires going to different places. The 200V input is odd, but apparently tube radios like this used a 200V supply for their B+. Since it's rated to handle 200V at 50Hz, I wonder if it would be OK to give it 220, 230, maybe even 240 volts if the line is guaranteed to be 60Hz.

The secondary is built of 4 square-section "strands" in parallel, there are at most 6 or 7 turns of it in a single layer. It's center tapped, but the tap wire is only one strand. Maybe the radio used some tubes with a 3-volt heater as well as 6.3 volts. It's rated for 168A continuous. That's a lot of amps.

Plenty of 1kVA transformers online but they're mostly 120/240/480 control transformers. I thought this one was pretty interesting since it's 1kVA at very low volts. Little risk of electrocution but definitely a fire hazard!