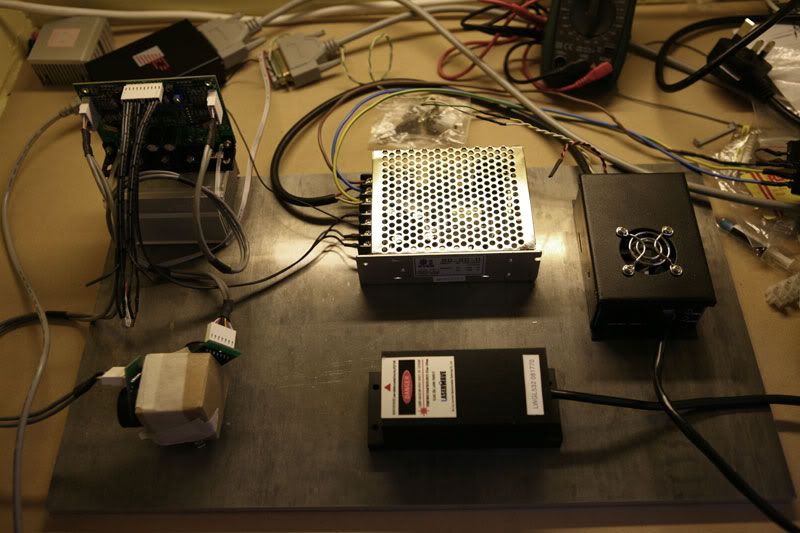

Well this is my gear, it is only layed out like this for testing, everything works spot on

This 470mm X 270mm 10mm plate will be installed just below halfway down the case.

I decided to make my case out of wood. I think i've made the right choice as its going to be used at home or maybe sometimes partys so asthetically i wanted it to look like a moderm piece of furniture, I think it'll look nice this colour. I used 18mm ply with a decent grain, this is rock solid strong as is, my next job is to install aluminium angle on the outside edges for added strengh and to hide the ply stripes, i'll also polish up the aluminium edges. The wood will be just waxed probably.

Case opened, the lid fits perfectly and i have something in mind to keep out dust. I have a pretty good cooling idea up my sleeve

This is the front, I have yet to cut the square hole for the laser but this will come after i've installed everything on the optical table. I just used Door stops for the 4 legs, they work perfect

Lid back on. clips on the side are handy. they hold the lid on solid and its nice & quick to remove.

Wood £23

Alu plate £40

fans will be about £40 for the 2. I'm using these: Noctua NF-P12 Vortex-Control 120mm Quiet Case Fan

It'll be a few quid for the aluminium angle to finish off

Jobs left to do:

Install back plate for ILDA interface, Power, key lock.

Install 120mm fans and filters

i have some very quiet ones lined up in brown.

Clean up the optical plate.

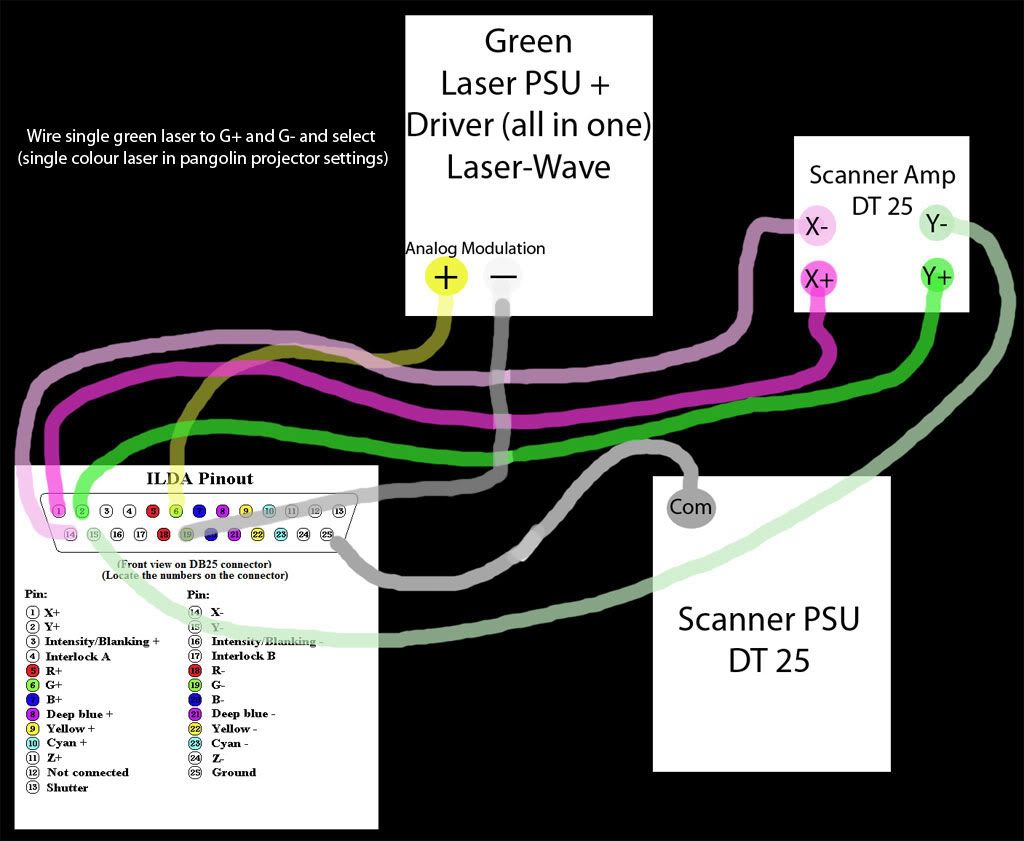

Install components to optical plate. I am setting this up for RGB. The optical plate will also be installed into the case so its quick to remove.

Align optics, mark out maximum exit aperture, remove the optical plate and cut out the square exit hole, install glass (still not sure, i'm sure you can get square camera filters)