- Joined

- Sep 20, 2013

- Messages

- 20,284

- Points

- 113

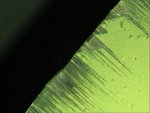

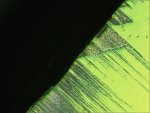

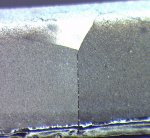

No problems here. Not a disagreement either. I have spent a fair amount of time trying to get these to be more accurate. Trying to get to 0.1nm of accuracy may be beyond the ability of these to accomplish. But, the work goes on. :yh: