- Joined

- Jul 10, 2015

- Messages

- 13,094

- Points

- 113

Great idea Red :beer:,

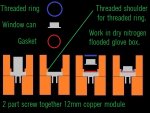

and to open the options up even more, we could step away from the 12mm module into a 20mm module, and start using M12 lens holders with <10mm optics.

I know I few members here might be excited at that......Alaskan

The thing is a lot of people have invested in many M9 x 0.5 threaded barrel lenses, I know I have quite a few........I suppose it could be built oversized at 20mm with an area to accept threaded barreled 10mm lenses in a 12 or 14mm threaded barrel, but we would need a screw in adaptor so we can use all our standard lenses......really might as well just make it a 12mm module to accept M9 x 0.5 lens barrels and if we get wider diodes later then adapt a new module.

It's best to use a G2 and cylindrical pair than a wider lens anyway, plus all the wider lenses would need to be made and bought, I have a tray full of containers holding all kinds of lenses and would need a new set......it's not practical or worth it until we have physically bigger diodes to accommodate.

If the person/persons having the modules machined went with 20mm modules they would also need to make M12 to M9 inner and outer threaded sleeves so we can use all out standard lenses, then someone would need to make 10mm glass and 12mm threaded lens barrels, but the 20mm module would also have to be longer to accommodate the longer focal length of the wider lens, 10mm glass vs. 6.35mm and compact hosts would have to be bigger.

I'm not against bigger modules, but it's not the important part, the backfill is what's needed.......maybe we should wait and see what comes next, I could see 24mm diodes right after a big 20mm module tooling up on our end, this is really more of a concept to tackle the 15w GBall of tomorrow that we really want to use, that and the 4W 520nm or what ever it may be.

Last edited: