- Joined

- Apr 29, 2007

- Messages

- 1,076

- Points

- 0

The problem with adding material is that the steel and the aluminum will expand and contract from heat at different rates making them warp the table when you turn it on.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

GooeyGus said:I dont see anything majorly wrong with the build. The extra mirrors are there because the client wanted it to be fully adjustable and that means adding in some mirrors that normally wouldn't be 100% necessary. The bottom sheet may be thin, but with the extra supports I really cant see it causing a huge issue. The differing metals isn't really an issue either. We're not talking about hundreds of degrees here, it will probably be barely above room temp... maybe as high as 100°F but that isn't going to cause enough of a differential between the metals to really fudge anything up.

If they can make cars with iron blocks and aluminum heads and still make the head gaskets hold, I'm sure this low-temp application will be fine. If you want to run the scanner in a 500 degree oven, you may run into some problems.

Phillip said:Hello Andy_Con.

I´m sorry, I don´t really know you but I must say some Thinks...

I´m in Lasers for now arround 7 years, and I wouldn´t get the idea ANYTIME to sell a Laser to a customer how you do it.

Yes , clear, we can discuss what is good and what not. But I think if you sell something to someone, it must have a minimum of Quality.

You use good lasers, that is OK ... About red we can also Discuss, it would be better if you use red´s with better beamdata, there are some on the market, they also aren´t the expensivest ones.

The next point is : Why do you Build the complete system so big? On the lenght you can get 20-30% smaller, maybe more. And on the first look on it you use 3 Mirrorholders for Nothing. Please think, more holders will say that there is more what could be misalign, and more what should be adjust. About the groundplate: You use 6mm aluminium... that is really really to Thin, you can add some material under the plate, but think on the bi-metal effect. And it isn´t as stable as a thicker aluminium plate. I can guarantee you that the system will be misalign in small time. Only one the transport from you to the Customer.

About the holders you are using I wouldn´t talk, much people use them, but for professional use, I wouldn´t take them.

You have build much systems! Really nice! But this doesn´t means that you know enought to build professional systems for others.

The system you build isn´t build by knowledge, it´s build by Price. That´s my thought.

By the Way: You should look on the laws, I think you are from UK, this is Europe, there are special Laws for lasers. Look on EN60825-1

Greetings,

Phil

Hello!Laser Ben said:Phil,

Great writeup, one thing I would like to point out is that for the hobbies, there is not too much better you can get on the red lasers without going DPSS. When you go to the DPSS lasers at 671nm, you lose much of the relative lumen/watt brightness, you would need 4 times as much power in DPSS compared to these lasers. DPSS is much more expensive, about twice as much so it doesn't fully make scene to go there unless you really need it.

--Ben

I dont see anything majorly wrong with the build. The extra mirrors are there because the client wanted it to be fully adjustable and that means adding in some mirrors that normally wouldn't be 100% necessary. The bottom sheet may be thin, but with the extra supports I really cant see it causing a huge issue. The differing metals isn't really an issue either. We're not talking about hundreds of degrees here, it will probably be barely above room temp... maybe as high as 100°F but that isn't going to cause enough of a differential between the metals to really fudge anything up.

andy_con said:firstly phillip you know nothing about the build, me or my client. you dont know what discussions have taken place between me and my client regarding the whole project.

which im not going to explain to you as its none of your business.

my client has seen my site and previous projects and knows exactly what he is buying and also knows i dont build professional systems.

if you had read previous posts in this thread you would know the reason for the projector being this size.

now reds....

there are lots of companies making lots of reds, each one different. indeed i probably could have got a tighter beam but it would probably be darker then 650nm and probably not built to the high standards as laserwave.

indeed the beam is big on the laserwave modules and most other modules but i have purchased a high quality laser that will last long, is that such a bad thing?!

everyone builds things different, but that doesnt mean to say your right and someone else is wrong.

the beams wont just fall out of alignment what are you talking about!

all the best

andy

Hello!wannaburn said:@Philip-

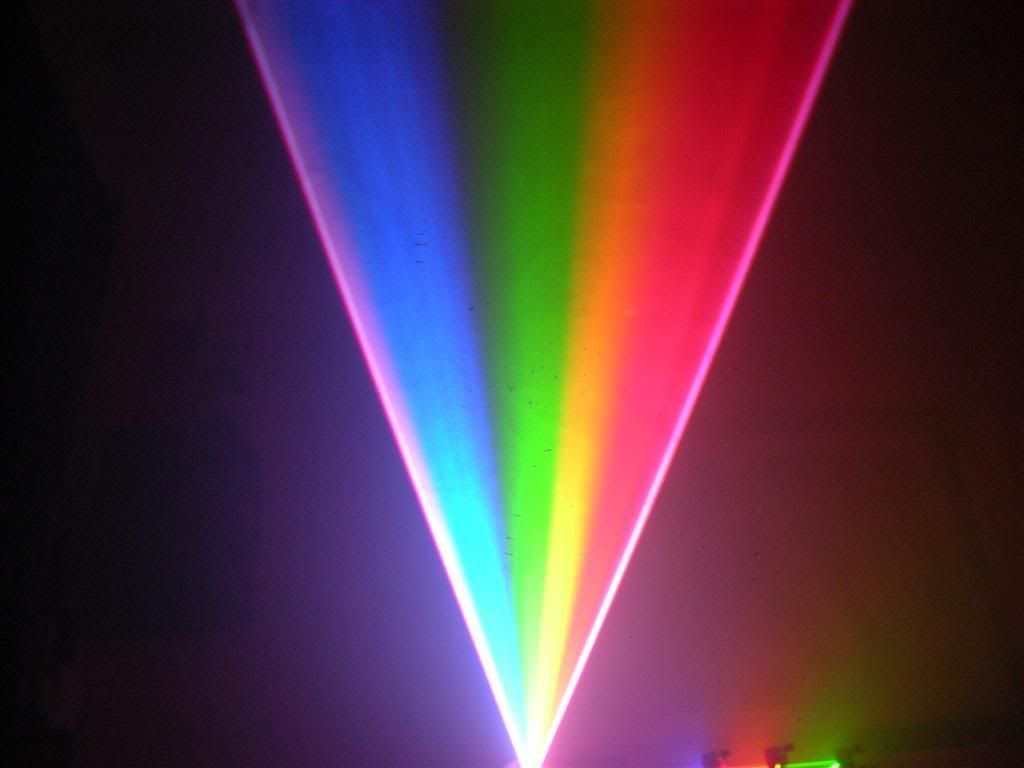

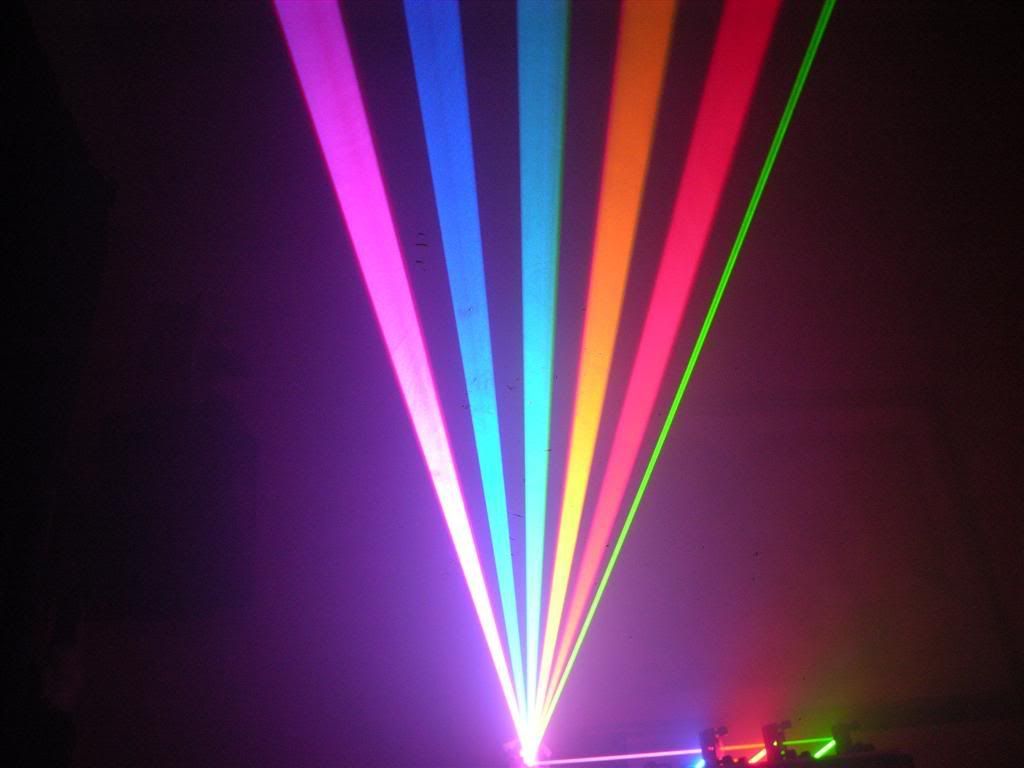

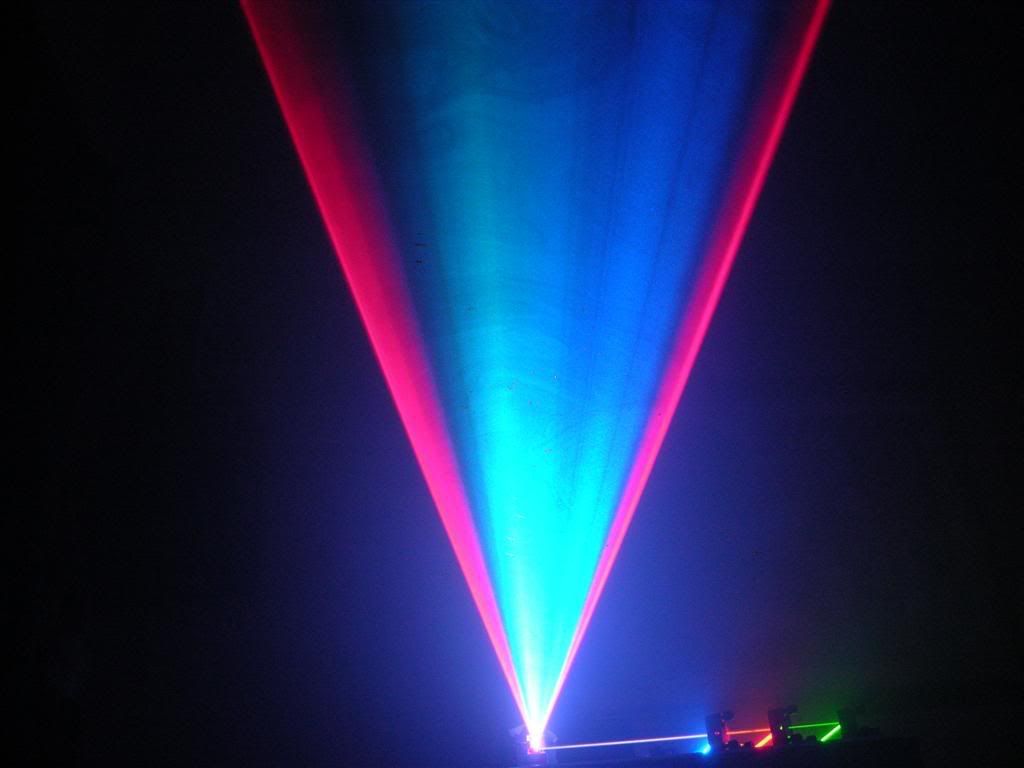

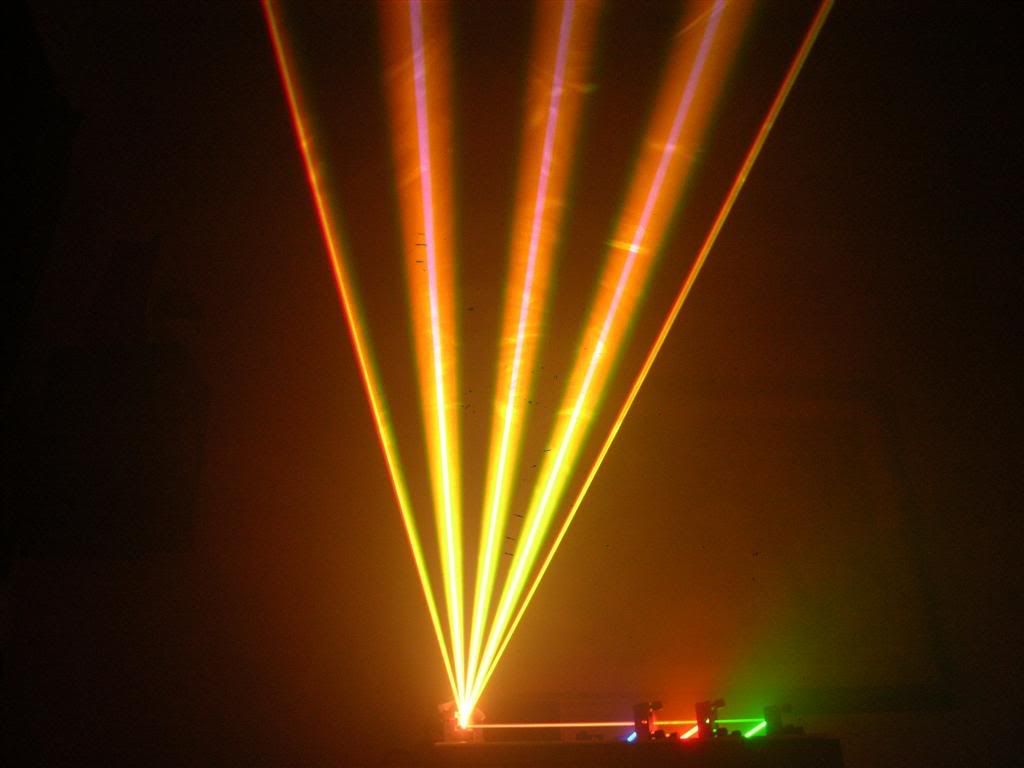

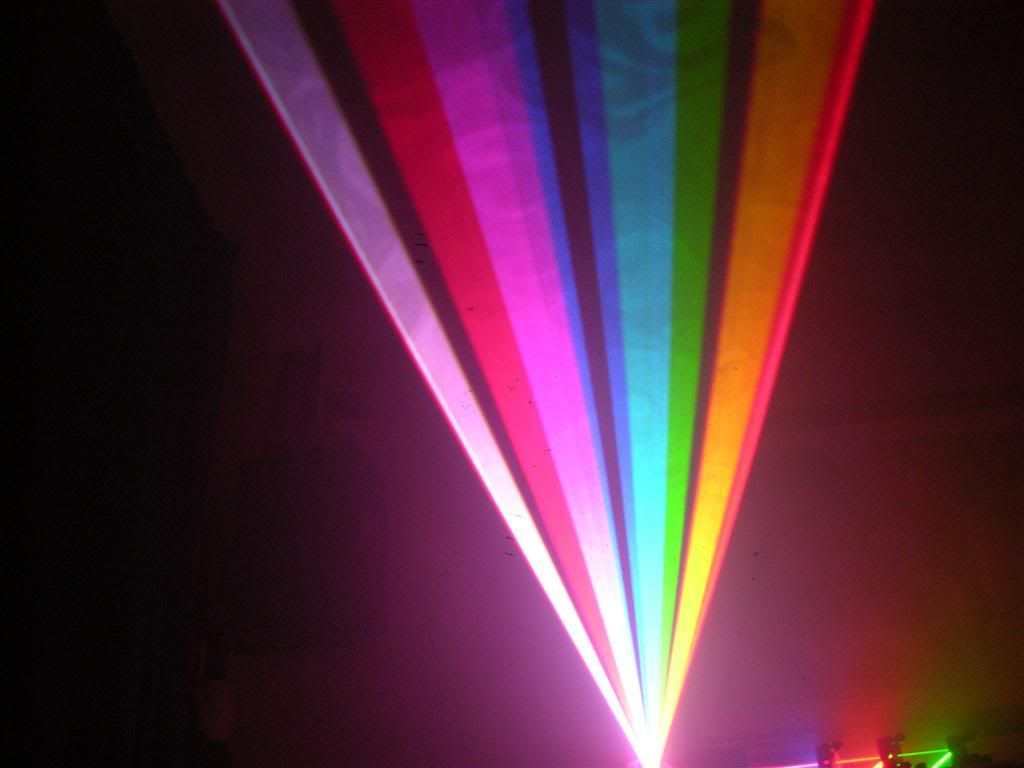

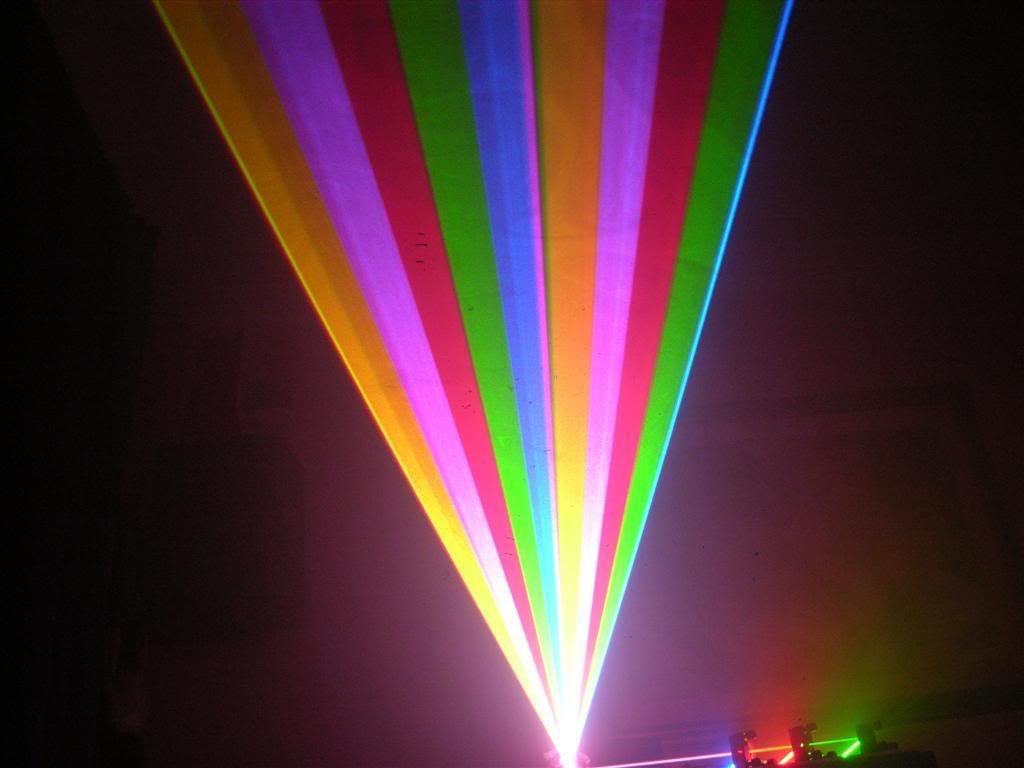

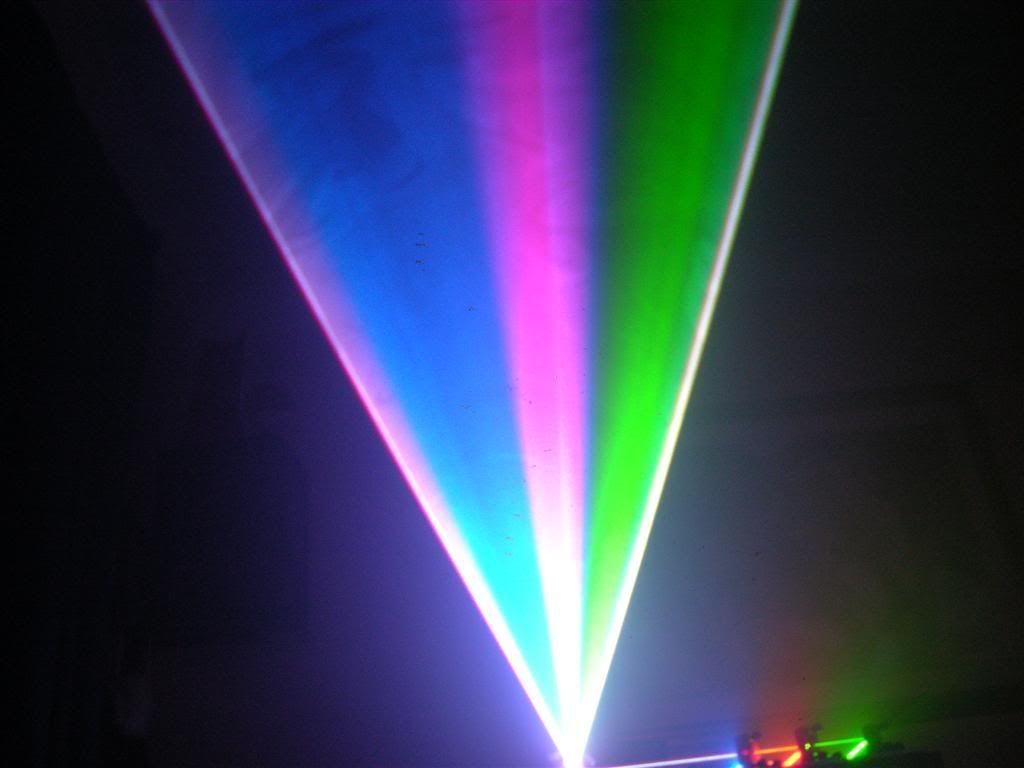

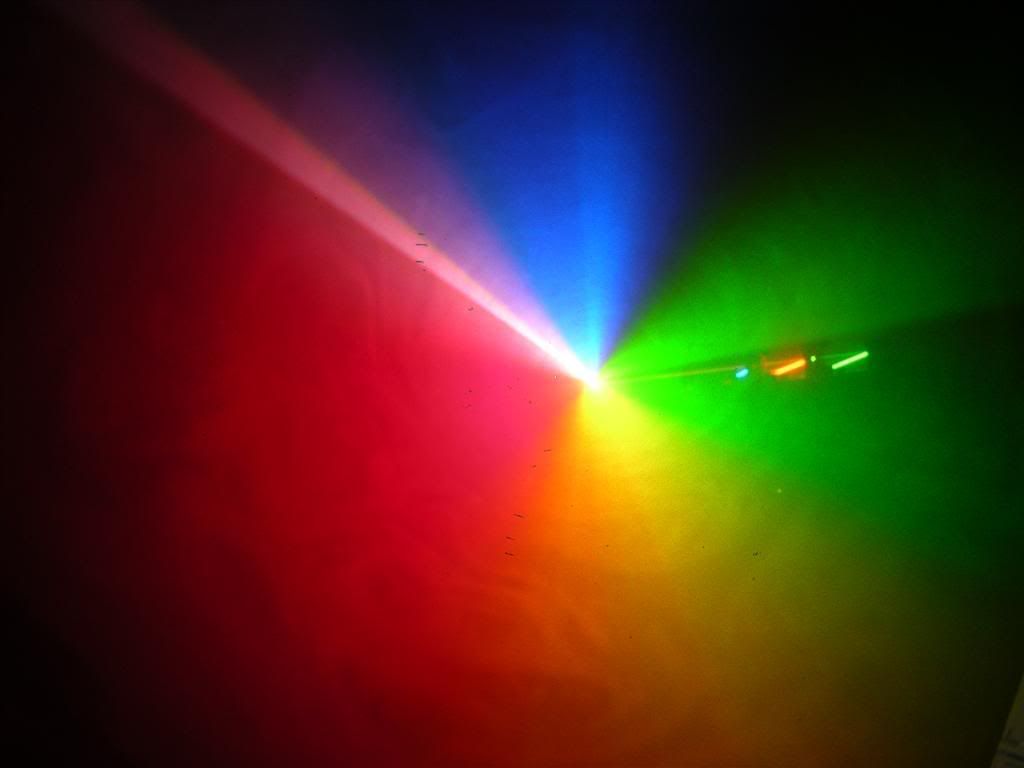

Arent you the proud builder of this in the pic? You can critique my builds any day