How did you remove the glue that holds the lens? I want to try to refocus my array for a tighter focus.

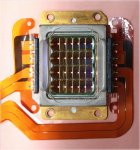

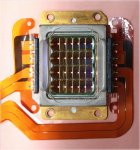

Optional: draw around the lens array with a permanent marker if you will want to reattach the lens array later on. The alignment of the lens array, with the diodes underneath, must be very precise and this might simplify matters a little. A few small spots of UV activated adhesive around the edge of the lens array can hold it in place and is not difficult to remove if used sparingly. Getting the alignment exact can be challenging. Note the thickness of the adhesive under the lens array edges. It determines the distance from the diodes to the lenses!

Use new single edge razor blade, or razor knife, or one which is at least very sharp. A regular knife blade is too think and may break the glass. It is helpful, but not required, to have the device immobilized so it does not move around while working. Be aware that the lens array is quite brittle. It is important to cut through the adhesive to separate the lens array. Do not try to separate the adhesive from the glass or pry upward on it. The adhesive is not epoxy, I suspect that it is polyurethane, it is strong synthetic rubber. It is harder than silicone sealer. When cutting, move the blade slowly and use substantial force. Expect to use several passes to cut through the adhesive.

The first cut will be vertical and right next to the glass, to cut off the adhesive that is next to the glass. Do the same on the other side. Next, cut horizontally, undercutting the adhesive adjacent to the glass. If required, make a number of cuts, to get most of the adhesive off the metal underneath. Do the same thing on the other side.

The next cuts require more care and will separate the glass from the metal underneath. This adhesive is not very thick here, so care must be taken to avoid putting too much pressure on the glass. Make sure the blade is horizontal and undercut the adhesive. Again multiple passes will be needed to do this safely. After removing the lens array, scrape off remaining adhesive. A sharp knife is not needed here. Be half-way careful though because the metal is quite thin and dents easily. This is not the only was to do this, but it is what I did. Very fine "music wire" might be able to do the cutting, but it did not occur to me at the time.