- Joined

- Dec 15, 2014

- Messages

- 6,773

- Points

- 113

Hi LPF,

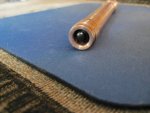

Her is a copper pen i machined in it is a PLP 520 B1 diode / G2 lens / 145mW

Takes 2-10440 cells. Enjoy folks, Beam shots after i eat supper..

Oh changing the set screw to a 4-40x 1/16 Brass..And will make a copper focus adapter later.

Rich

Her is a copper pen i machined in it is a PLP 520 B1 diode / G2 lens / 145mW

Takes 2-10440 cells. Enjoy folks, Beam shots after i eat supper..

Oh changing the set screw to a 4-40x 1/16 Brass..And will make a copper focus adapter later.

Rich

Attachments

Last edited: