- Joined

- Dec 11, 2015

- Messages

- 1,628

- Points

- 113

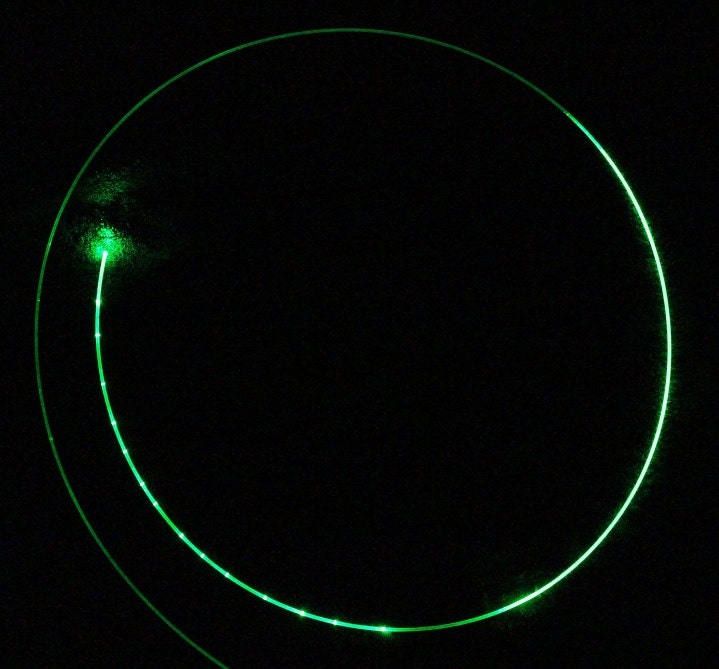

My local electronics store started carrying EL Wire, and the whole range of EL - Pads, tape, wire, adapters and drivers etc... I happily found out when receiving their flyer and went to pick some up ASAP. I've had my eye on EL wire for a very long time, so this was pretty exciting to me. I can easily say EL wire is one of my favourite aesthetic lights sources. Here's a couple pictures:

I opted for light blue:

<wtf>

Outfitted it on my stairs:

Really cool stuff. I'll definitely be obtaining more EL in the future!

-E.P.

I opted for light blue:

<wtf>

Outfitted it on my stairs:

Really cool stuff. I'll definitely be obtaining more EL in the future!

-E.P.

Last edited: