IgorT said:[quote author=chimo link=1194375801/120#124 date=1203094834]I think I may have to pick up some to play with. Looks like a versatile little chip.

That's great. If more of us play with it, one should get it right sooner or later..

I mean, i'll try my best, but my bet is on you two...

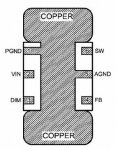

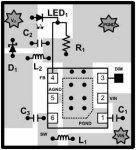

On the other hand, the 3410 has a circuit in the datasheet, that is pretty much perfect for driving a LD from a single cell Li-Po (Design example 6).. All it needs is two 4.7uH inductors. It's the circuit i posted a page or two ago.

Since almost all the requirements match, i'll just use the recommended parts and hope for the best.[/quote]

Did you find any in a SOT23 package or are they just available in the LLP?