- Joined

- Oct 27, 2008

- Messages

- 169

- Points

- 0

Re: Build Tips - 7 Color Laser Using Adjustable Sled Mount/Heatsinks

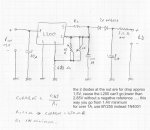

a note on using the trimmer to control the output power. The combination of a 100ohm trimmer and 10 ohm resister doesn't give you much control.

trimmer value~net resistence

10~5

30~7.5

40~8

70~8.75

90~9

the change is basically going from full to half power almost instantly (assuming 5ohm cuts output in half).

a note on using the trimmer to control the output power. The combination of a 100ohm trimmer and 10 ohm resister doesn't give you much control.

trimmer value~net resistence

10~5

30~7.5

40~8

70~8.75

90~9

the change is basically going from full to half power almost instantly (assuming 5ohm cuts output in half).