Jay got my unit today and assembled it in under 10 minutes. I have to say the finest unit of yours that I have yet. Cant wait for the SS 18650.

I thought I would document the process that I use for the people that are thinking about picking up one of your hot units. Obviously this is my third build and am in no way and expert. Constructive criticism is graciously accepted.

First off got some diodes form Daguin. Extremely well packed as always.

Then the Aixiz modules from Jay. Remember you will discard the back of the Aixiz module as it is unnecessary for this project.

Now to the presses.

I currently use a

diode press tool from Flaminpryo $15 LINK. This tool is great and would suggest to anyone who plans to build a laser. Plus it will countersink the diode past flush.

You can use a pair of large pliers instead of a vice as well to press the diode.

If you don't have a diode press tool you can use a 3/16 socket for pressing the diodes into the Aixiz module. The previous method is better but this will work in a pinch.

Press it with a vice until the diode is flush with the module.

When it is in it should look like this.

Now comes the fun part. Get all your stuff out. You will need a soldering iron, shrink tubing, solder, pressed diode in the Aixiz module and your hot kit host.

Put the shrink tubing on the wires and push them back toward the host.

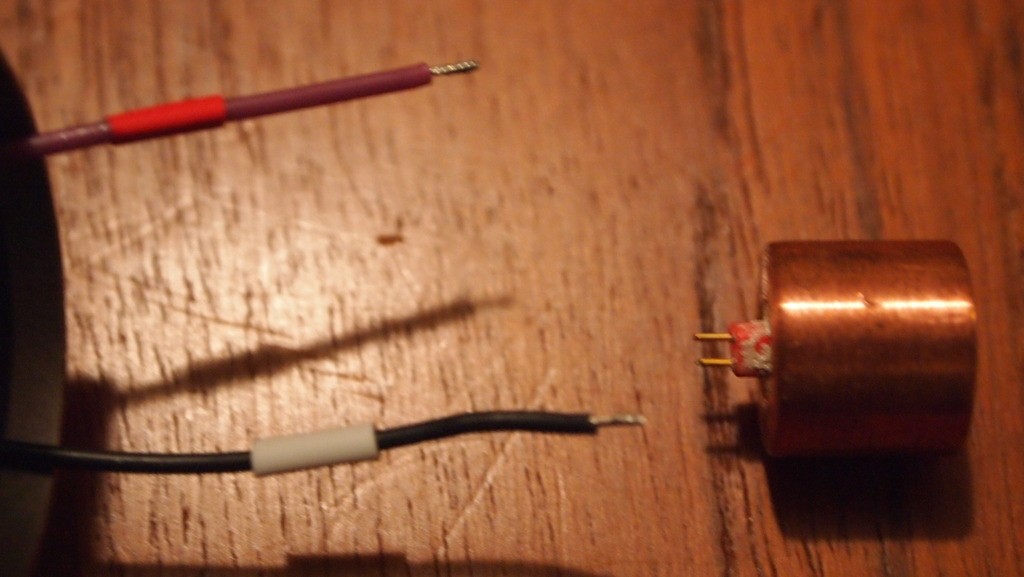

Next we will solder the diode to the hot kit wires. Here is a pinout for this diode. It does say Blu Ray but the pinout is the same.

First get your flux and dab a small amount on the diode pins and your wires. Then get some solder loaded onto your iron. Hold the wire up to the diode pin and quickly touch it with your iron. The flux will draw the solder to the joint very quick. Repeat with the other wire pin.

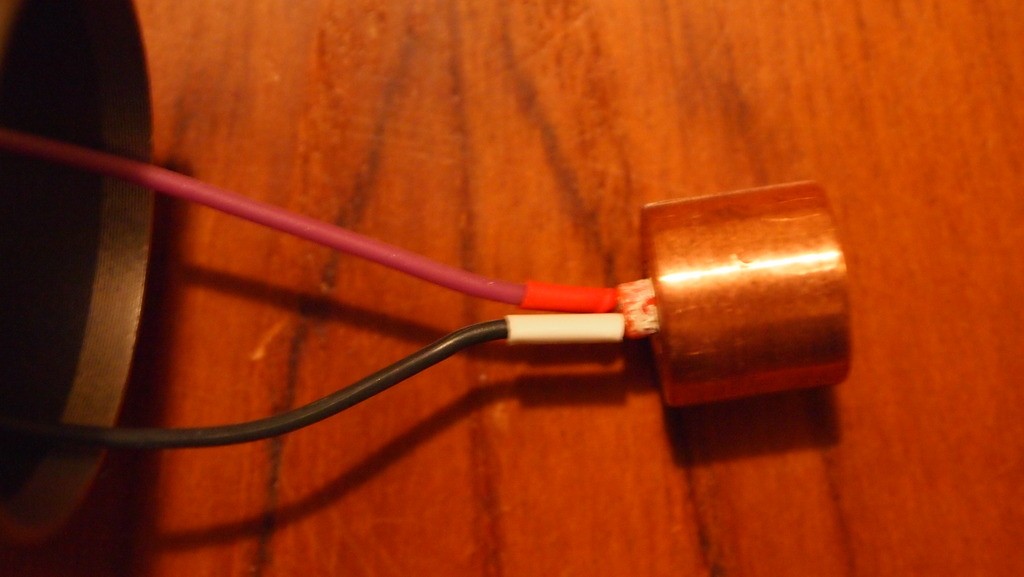

When you are done it will look like this.

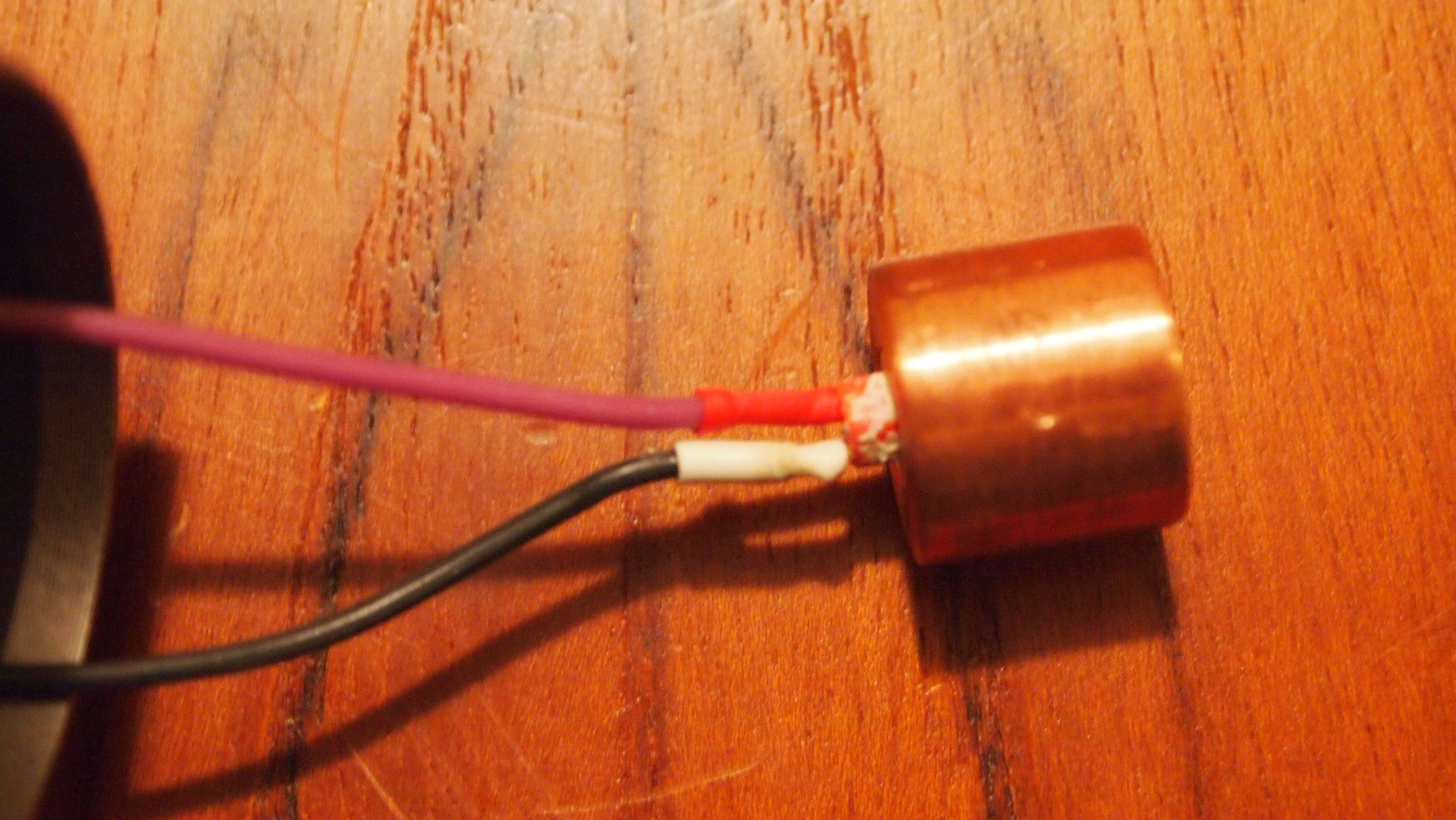

Next after the connections have cooled move your shrink tubing to the head of the diode covering the solder points and pins.(important to let it cool before you try to slide the shrink tubing down because it will shrink as soon as it hits something hot and will not go all the way up)

Finally I like to use a butane jet lighter and hit the shrink tubing with it. If you don't have one you can just rub your iron over the shrink tubing until it is snug.

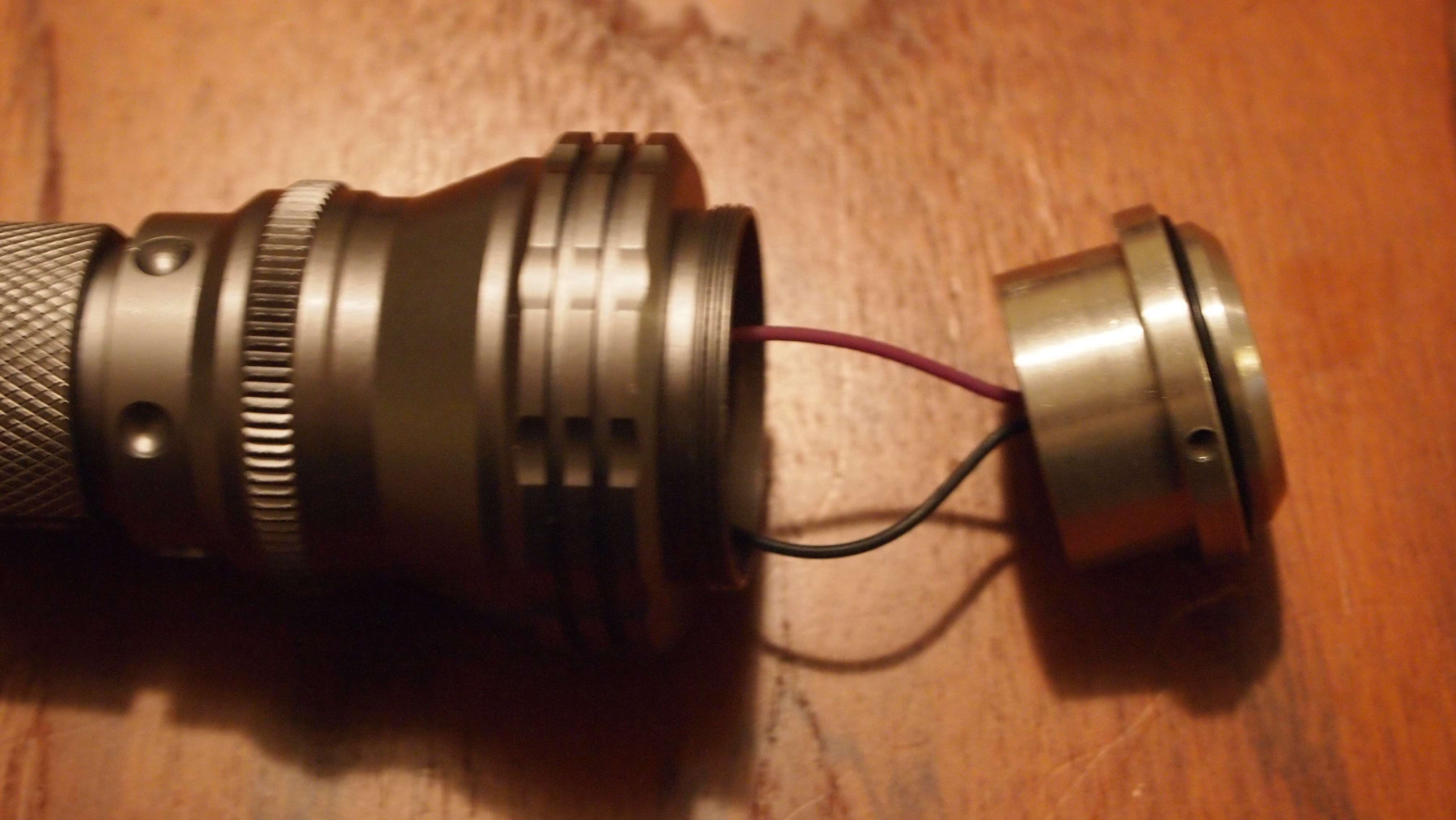

The hard part is over. Now just put your Aixiz module in your heat-sink and tighten the set screw with your allen wrench.

Place the heatink gently in the host making sure not to pinch or twist any wires.

Screw the top on and put in a lens.

Now you are ready to lase.:eg:

Hope this was useful to somebody.

Jay on a side note the heat-sink is definitely working wonders on this thing. Ran it for 90 seconds and it has not kicked in the overheat protection yet.:beer:

I will post a review tonight when I get home with some beam shots. Can't wait for my lenses.