Hello all,

Iam not very good with the laser tech.just have idea of lasers and what they are capable of.

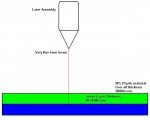

i have a requirement,where i need to cut a special sticker material which is of 2 layers.the laser shld cut only the top layer(green layer).this process has to be very accurate.so iam not sure whether such operation is possible with laser or not.

need some desperate help here.

Regards.

Iam not very good with the laser tech.just have idea of lasers and what they are capable of.

i have a requirement,where i need to cut a special sticker material which is of 2 layers.the laser shld cut only the top layer(green layer).this process has to be very accurate.so iam not sure whether such operation is possible with laser or not.

need some desperate help here.

Regards.