(I have since posted the answer to my own question, I had improperly connected the 9-in-1 multimeter. See my updated reply to this post on page 3. I included a picture of my recent testing of the NUBB24 diode running at 3A.)

DISREGARD THIS POST—— SEE PAGE 3

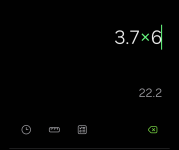

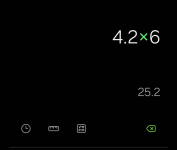

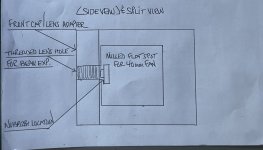

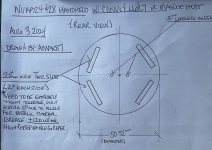

Another discussion side topic, with using my li-po batteries to run drivers for the NUB diode array series of the 445nm blue lasers, I really haven’t seen a Vf increase when pushing. 4-5+ Amps? I have in my possession, NUBM31, NUBM37, NUBM35, NUBM38, NUBB23 and NUBB24 arrays and so far, none of them have had the same increase as we see with the NUBM47, NUBMOF, or Osram 8W diodes? With pushing 5+Amps, you would think you would see 4.4-4.6Vf? For the NUBB24, you would think you when then see the diode array pulling closer to 33-34Vf? But that’s not the case at all, with my experience, with the rise in current, and driving them for 30-40seconds, I see a drop in Vf and then they stabilize around 0.12V lower, they should pull 4V at 3A, but they actually pull less.. I’m not sure if this is happening because I’m running TEC plates and fans for cooling, and I don’t let the temps ever exceed 50-60*C at the heatsink.. I’m going to hook up my NUBB24 setup tonight and post my results pushing 3A, 4A, 5A, and maybe 6A.. with the data sheet info, they appear to be pretty close to the NUBMOF in terms of output.. that would be awesome if they are because pushing them to 5+ A should yield 8W+.. putting the NUBB24 around 60W, and the NUBB28 in the 80W range, and that’s modest, they could easily handle 5.5-6A and yield 8.5-9W per diode.. I wish I had a bigger LPM..