- Joined

- Jan 19, 2009

- Messages

- 2

- Points

- 0

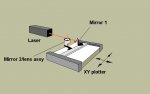

I'm an electrical engineer currently trying to design a DIY rapid prototyping machine. It will be my own version of a Laminated Object Manufacturing(LOM) machine. Basically it's an xy laser plotter that has a table moving on the z axis. It cuts profiles out of paper and builds objects by gluing the paper together layer by layer. I'm looking to build my own laser assembly that will be able to cut kraft paper at a decent speed. An example of kraft paper can be seen here uline.com/BL_1951/Kraft-Paper-Rolls it's the stuff that paper bags and package stuffing material is made out of. I don't really want to spend hundreds on/build a CO2 laser so I'm really hoping i can just use a diode. Possibly more than 1 I guess going through a collimating lens and setting my cut point at the optimal convergence point.

So, after lurking this site, I've come to the conclusion that I'll need to build a "lab" laser, but I have a few questions. The laser doesn't need to be super precise or have a small beam width because I won't be cutting anything really small or detailed, nothing like some of the xy plotters I've seen on youtube.

1. Is the noisy DC voltage coming out of a "wall wart" power supply going to affect the LD driver or laser?

2. What wavelength/color would you recommend for my application and where do I get it?

3. I'm thinking the zbolt heatsink/housing is gonna be my best choice, but what about collimating lens?

4. I'm an electrical engineer so building my own driver is no problem, what current range should I be looking at?

Thanks

Chaston

So, after lurking this site, I've come to the conclusion that I'll need to build a "lab" laser, but I have a few questions. The laser doesn't need to be super precise or have a small beam width because I won't be cutting anything really small or detailed, nothing like some of the xy plotters I've seen on youtube.

1. Is the noisy DC voltage coming out of a "wall wart" power supply going to affect the LD driver or laser?

2. What wavelength/color would you recommend for my application and where do I get it?

3. I'm thinking the zbolt heatsink/housing is gonna be my best choice, but what about collimating lens?

4. I'm an electrical engineer so building my own driver is no problem, what current range should I be looking at?

Thanks

Chaston