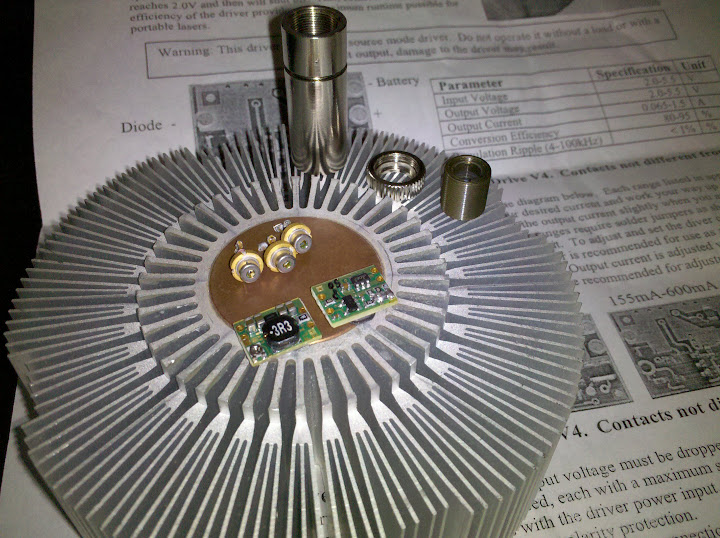

Uh, it's a stock intel E29477-002 socket 1366 heatsink.

Though personally I prefer these.

While they don't have copper core's, they cost 1/4 what the above heatsinks do.. A whopping $3.18 in quantity.. which is why I bought 20 and my supplier has a few thousand in stock.

I can get the above intel 1366 heatsinks, as well as intel 775 ones that have a lower fin density fairly cheap as well, but like I said, not nearly as cheap as these aluminum ones.

Expect to see them popping up in the BST bored for aixiz modules as soon as my bag of modules actually gets here.

Though for someone wanting to go all out, i'd probably suggest this.

Though with copper fins, it's not going to be machinable, diameter wise.

It's the i7 extreme stock heatsink. The next step up from the one boscoj is using.