- Joined

- Nov 4, 2014

- Messages

- 1,146

- Points

- 63

Hey LPF,

Here is the situation. I just ordered 2 Kryton Groove hosts seen here. To build a 1w 520nm from DTR seen here, with the X-drive driver. From my research I think I will be needing a 520nm AR Coated Three Element Glass Lens since I am going for beam quality not burning stuff.

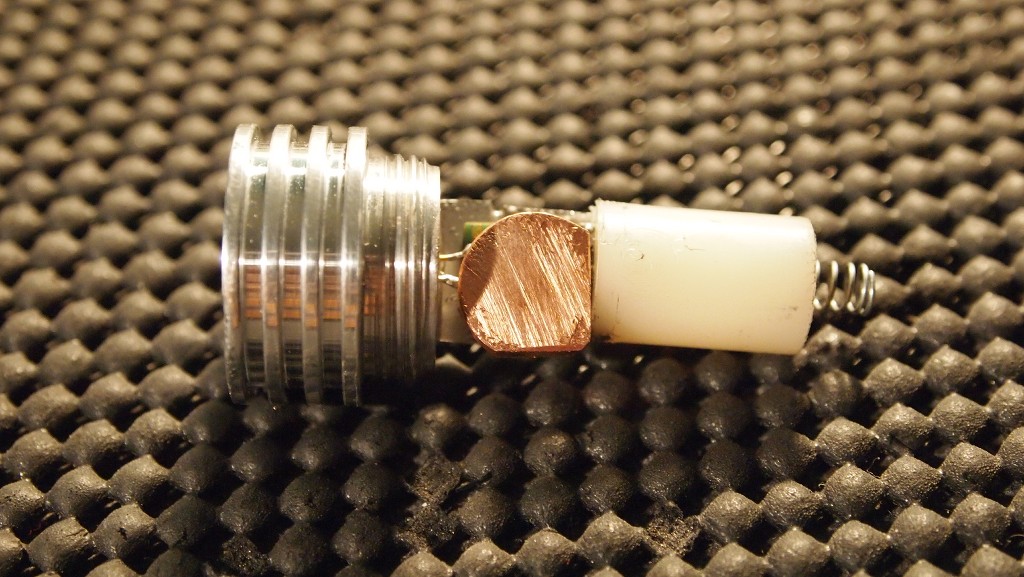

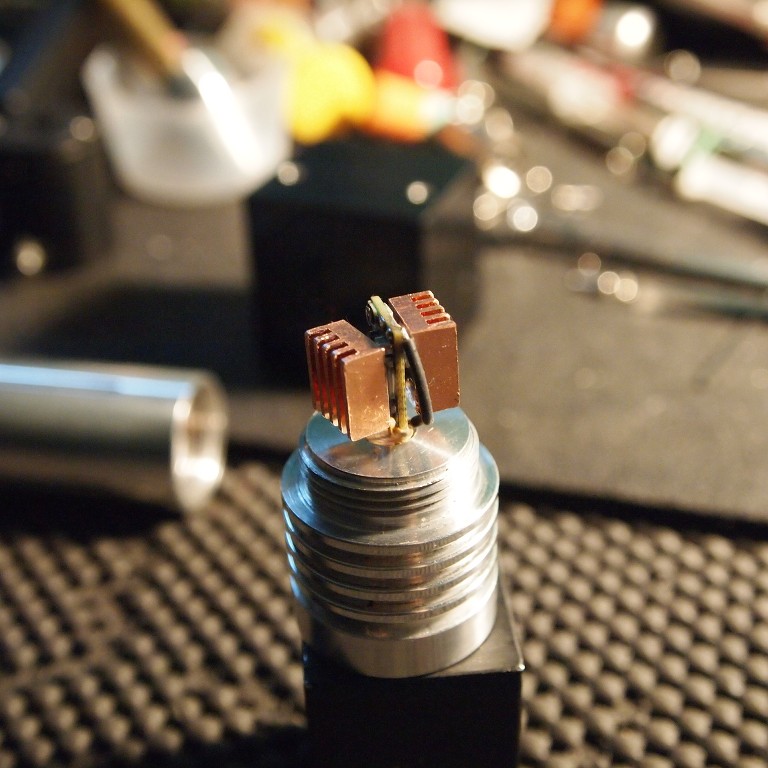

My concerns are this. I have never built a laser and this host doesn't seem like its as cut and dry as others I have read about. From watching the tutorial It looks like I need to build a modified ground lead and solder a heat sink on the driver. I did a search for these and didn't find anything that clearly explained how to do this enough that I feel confident to go for it alone. Considering the cost of this diode I would like some help with the build.

Is there anyone in my area that is willing to help me with my first build? I can compensate you for your time or buy beers and pizza ext.

The second Kryton is a 5.6mm and I will be building a 462nm 2W at a later time hopefully on my own after having some help on the first build.

Here is the situation. I just ordered 2 Kryton Groove hosts seen here. To build a 1w 520nm from DTR seen here, with the X-drive driver. From my research I think I will be needing a 520nm AR Coated Three Element Glass Lens since I am going for beam quality not burning stuff.

My concerns are this. I have never built a laser and this host doesn't seem like its as cut and dry as others I have read about. From watching the tutorial It looks like I need to build a modified ground lead and solder a heat sink on the driver. I did a search for these and didn't find anything that clearly explained how to do this enough that I feel confident to go for it alone. Considering the cost of this diode I would like some help with the build.

Is there anyone in my area that is willing to help me with my first build? I can compensate you for your time or buy beers and pizza ext.

The second Kryton is a 5.6mm and I will be building a 462nm 2W at a later time hopefully on my own after having some help on the first build.