Here I slowly turned it up to 8 amps after breaking the fiber then cleaving it with wire strippers and stripping it again, actually cleaved it pretty well.

Even with the air moving it pumped in so much energy that the clothespin was fully lit, I only touched on 8a for a couple of seconds, I can see how running at 8-10a with a focusing lens these would make great home CNC cutters, how the output looks collimated through a lens at 15 feet I will find out as there are multiple emitters focused into the fiber, I would think they would be scrambled unlike the FAP bundle but we shall see.

We are supposed to use a scoring tool at the tip of the connector then pull the excess fiber away causing it to break at the score line, then polish with the coarse then 3 micron and finally 1/3 micron sheets, I am waiting for a scoring tool from China, it won't be here for weeks.

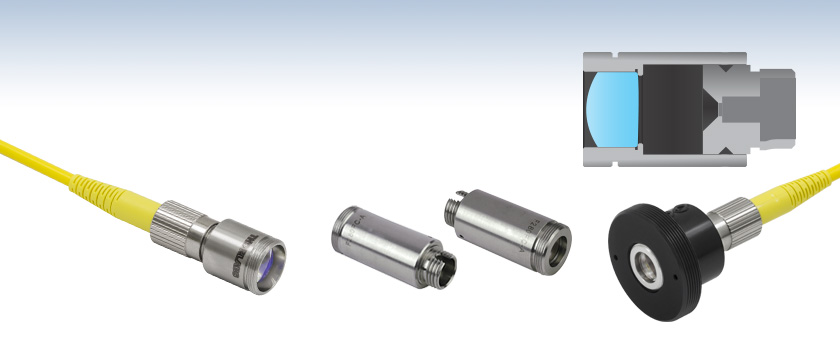

It may be possible to make a holder and set a lens in front, but keeping smoke and humidity away from the fiber end is likely a good idea, I plan to mount in

THIS and use the supplied lens filling about 80% of the lens for as much reach as possible.

HERE is the scoring tool I ordered.

---edit---

Looks like you put a fan on that to keep the smoke from depositing onto the end of the fiber, good idea, sure does burn well coming out of that glass waveguide.

I can't take credit for that, it's just my window AC blowing across the room, well across the ceiling and down the big mirror on the wall in front of me and back across this table, it did seem to work out somewhat and looks like a fan blowing at me, but it's just how I have the air set up to circulate. :beer: