- Joined

- Feb 12, 2016

- Messages

- 589

- Points

- 63

Thank you for watching.

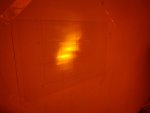

I already started to think that no one is interested in this chip and my pictures any more. Tomorrow I will post more test results.

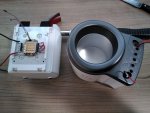

These multi lenses are generally crap, this is what we know from trying many previous arrays with such kind of "general" optics from PJs like A130, H1600, V1... but if your objective is not to make a long distance beam, just for focusing on phosphor is might be fine.

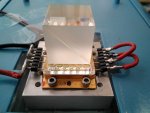

Is this one driver for both Nichia and Osram (85V and 110V output)? I thought that there are different drivers for each chip.

12V input looks too low to me, too - the input current has to be very high and would be hardly achievable from other batteries than LiPo. It is strange because the similarly looking drivers (I bought one from ali) for NUBM08 block have 24V input like one would expect for such wattage.

What is your objective with these batteries? I hope not to make a portable ice cooled device capable of Nichia beaming for more than 25 min???

I already started to think that no one is interested in this chip and my pictures any more. Tomorrow I will post more test results.

These multi lenses are generally crap, this is what we know from trying many previous arrays with such kind of "general" optics from PJs like A130, H1600, V1... but if your objective is not to make a long distance beam, just for focusing on phosphor is might be fine.

Is this one driver for both Nichia and Osram (85V and 110V output)? I thought that there are different drivers for each chip.

12V input looks too low to me, too - the input current has to be very high and would be hardly achievable from other batteries than LiPo. It is strange because the similarly looking drivers (I bought one from ali) for NUBM08 block have 24V input like one would expect for such wattage.

What is your objective with these batteries? I hope not to make a portable ice cooled device capable of Nichia beaming for more than 25 min???