Hello friends.

few weeks ago my 1600mw blue laser went down. It was a prebuild Laser for 50eu from china and actually quite decent. The diode suddenly only put out half its usual power, also the spot looked weird, not like it always did. Tried different batteries, no sucess. Now i want to take the chance to finally put something together, something i nerver did, but i bought a bunch of stuff already 1 or 2 years ago, different parts, diodes, soldering iron etc.

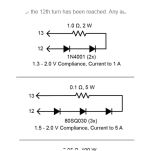

So i managed to tear that thing down which wasnt quite easy, now i basically just want to put in a 400mw red laser diode from Mitsubishi i think. Have 2 points of concern now, 1 is soldering the cables to the right spot/pole, 2 is turning down the potentiometer on that driver. I want to reuse it, i hav another, probably better one, but its to large for that casing. The previous diode was 1600mw so i will have to turn it down...anybody has an idea how to proceed, so i can make sure not to destroy the diode but also not run it way below what it can handle? here are some pics, if anybody needs a better or bigger one i will try to deliver, its just always a pain with this very small sized pics.

edit: i just realized 2 things, 1 the red-brown cable on the driver, it is so short, it cant even reach the diode through that aluminum cylinder. Is it possibly that it must be put into that very small hole? i marked it on the last foto. Im really a noob so this is all just guessing. That would mean that only 1 cable, the black one, reaches the diode? But why does it have 3 contacts then? Hmm

few weeks ago my 1600mw blue laser went down. It was a prebuild Laser for 50eu from china and actually quite decent. The diode suddenly only put out half its usual power, also the spot looked weird, not like it always did. Tried different batteries, no sucess. Now i want to take the chance to finally put something together, something i nerver did, but i bought a bunch of stuff already 1 or 2 years ago, different parts, diodes, soldering iron etc.

So i managed to tear that thing down which wasnt quite easy, now i basically just want to put in a 400mw red laser diode from Mitsubishi i think. Have 2 points of concern now, 1 is soldering the cables to the right spot/pole, 2 is turning down the potentiometer on that driver. I want to reuse it, i hav another, probably better one, but its to large for that casing. The previous diode was 1600mw so i will have to turn it down...anybody has an idea how to proceed, so i can make sure not to destroy the diode but also not run it way below what it can handle? here are some pics, if anybody needs a better or bigger one i will try to deliver, its just always a pain with this very small sized pics.

edit: i just realized 2 things, 1 the red-brown cable on the driver, it is so short, it cant even reach the diode through that aluminum cylinder. Is it possibly that it must be put into that very small hole? i marked it on the last foto. Im really a noob so this is all just guessing. That would mean that only 1 cable, the black one, reaches the diode? But why does it have 3 contacts then? Hmm

Attachments

Last edited:

![DSCI1602[1].JPG](/data/attachments/57/57189-05ac33b264bf33eb52d3ea4e590a9370.jpg?hash=BawzsmS_M-)