aXit

0

- Joined

- Sep 15, 2009

- Messages

- 206

- Points

- 0

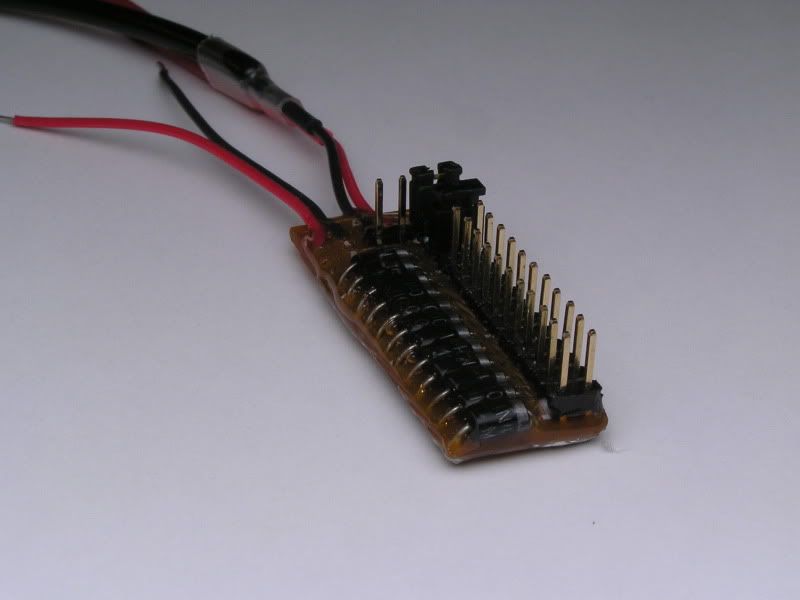

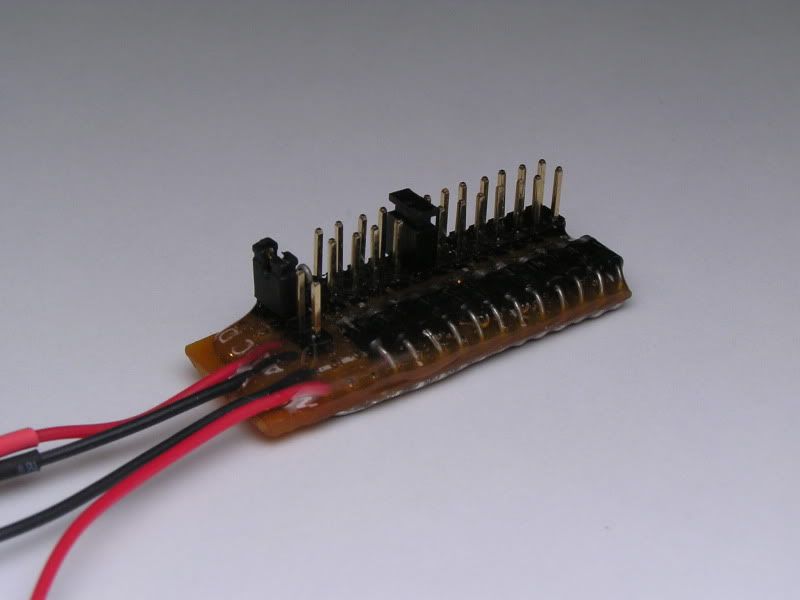

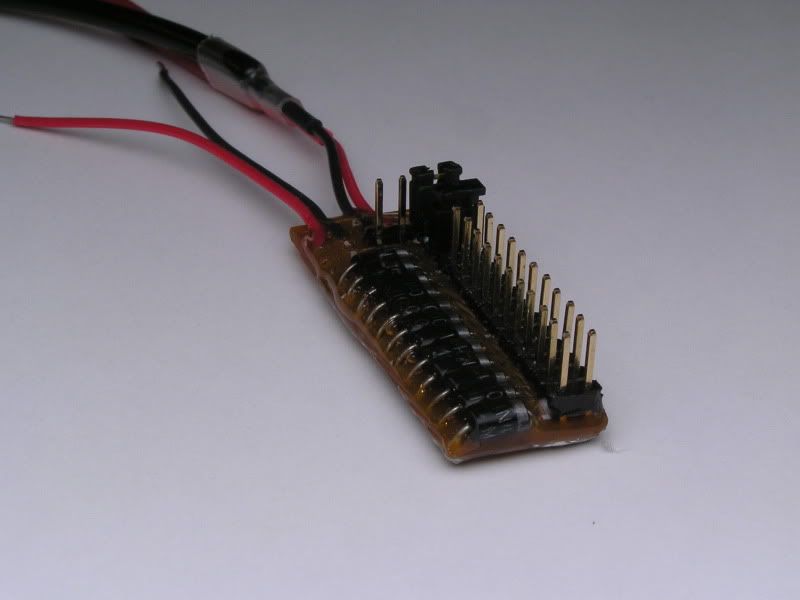

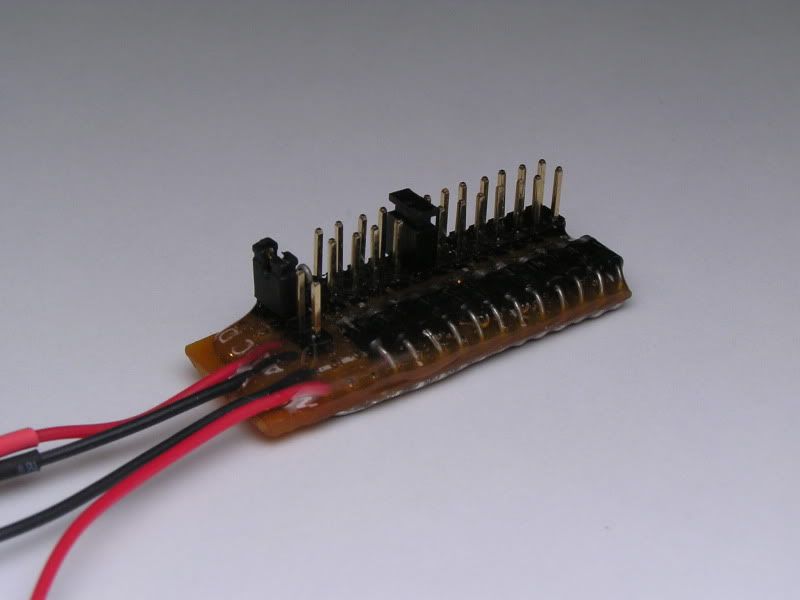

Just thought I'd share my version of a test load.

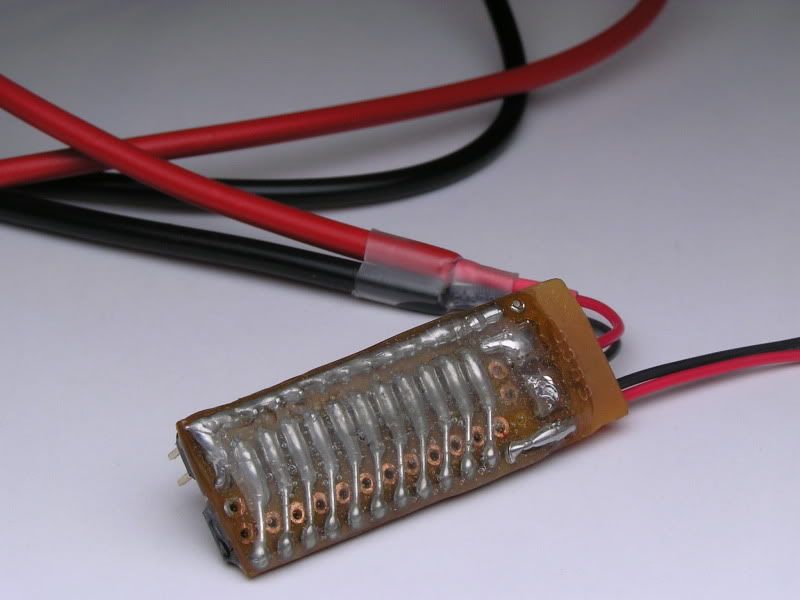

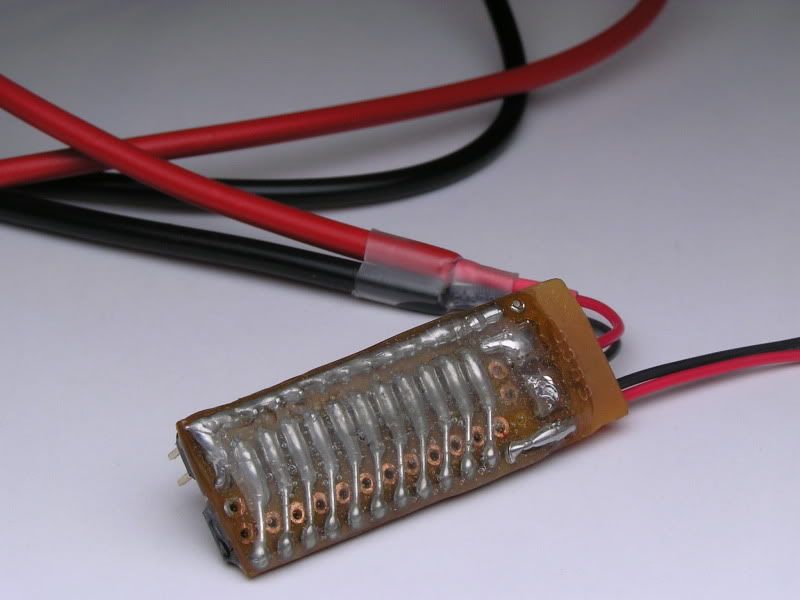

It's kind of a rip off of HIMNL9, with the adjustable jumper; and epoxied up just like flaminpyro's.

(Sorry about the glare on the epoxy there)

It's selectable through 0.7V-8.75V in 0.35V steps by moving the jumper over 1N400x diodes, or shorting out a schottky (forgotten the part number) for the half steps.

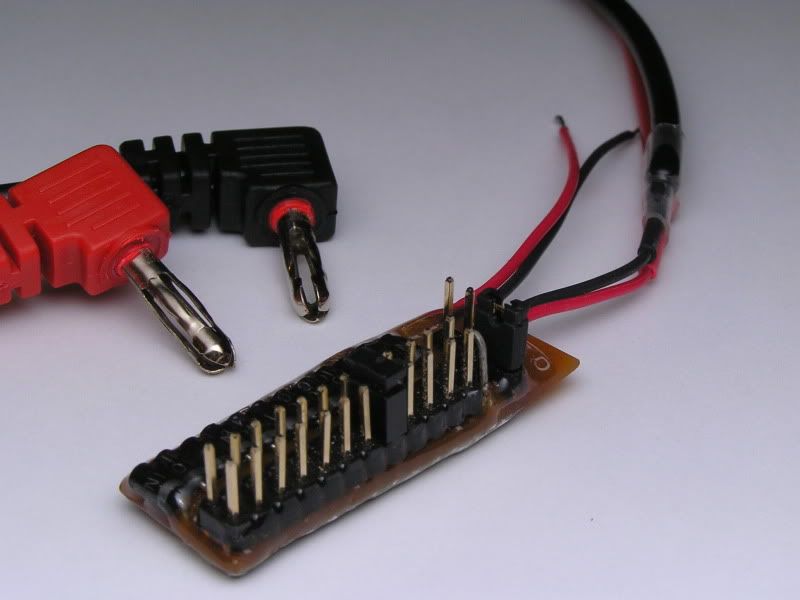

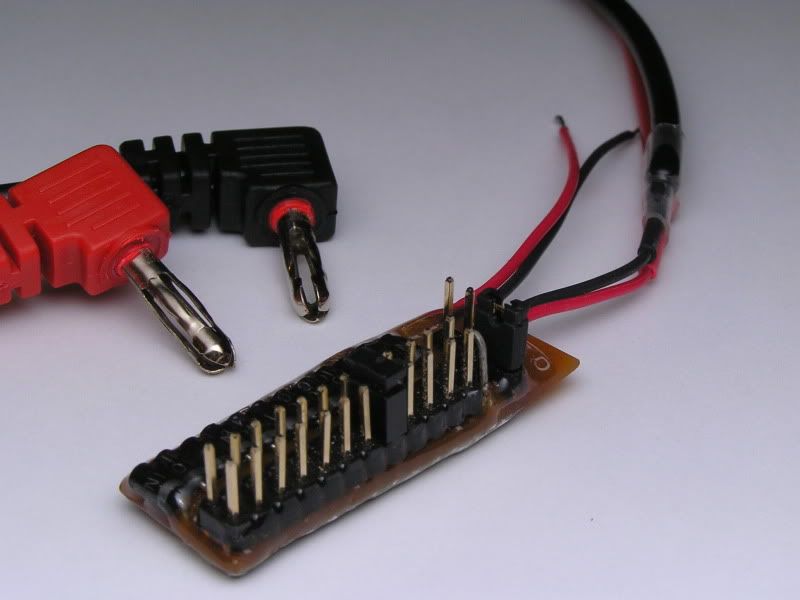

It's connected straight to banana plugs for the current reading on my DMM, or I can put a 1 Ohm resistor on the pins above those two wires for voltage measurement.

Hope you like it, or feel inspired to make your own. (thanks HIMNL9)

aXit.

It's kind of a rip off of HIMNL9, with the adjustable jumper; and epoxied up just like flaminpyro's.

(Sorry about the glare on the epoxy there)

It's selectable through 0.7V-8.75V in 0.35V steps by moving the jumper over 1N400x diodes, or shorting out a schottky (forgotten the part number) for the half steps.

It's connected straight to banana plugs for the current reading on my DMM, or I can put a 1 Ohm resistor on the pins above those two wires for voltage measurement.

Hope you like it, or feel inspired to make your own. (thanks HIMNL9)

aXit.