Hi LPF, I know there are tons of 520 builds out there but I'd just like to share what I've been up to. My build isn't complete since I'm waiting on a few more parts to arrive in the mail (a battery contact board and thermal adhesive) but for the most part, it's been going well. I'll also share some of my issues and how to avoid them.

I had a nice conversation with Immo1282 about his Convoy builds and thought I'd make a little writeup tutorial on how to do it for anyone wondering.

The first thing I did was order a Convoy S2+ host from Mountain Electronics. They're pretty good and their shipping was reasonable in price and time. The blank host is nothing special, it just comes with the end cap, a middle section for a 18650, a top part with a lens, reflector, and pill, and finally some extras in the inside like an extra spring.

Here is the pill and the host. The pill contains a little screw-in retaining ring on the bottom to hold the contact PCB that goes against the battery.

The next step was to order the laser and the driver. I bought the 50mW Osram 520nm diode from DTR's shop, with the driver included in the 20mm casing. Heads up- while the driver he includes is the LDSE500 (a good boost driver), the board is pretty long and I ran in to trouble fitting it in. I would recommend using a round driver like immo1282 did.

The build in immo's thread goes a little like this image he gave me:

As you can see, the aluminum piece should be cut down as much as possible. I can't do this because the driver is too long. The issue with this is that when the whole pill/heatsink assembly is too long, the top of the flashlight can't thread on to the body. I had to desolder the driver from the diode and attach leads on both ends. Since the board is too wide to fit horizontally in the pill, I had to machine out the top (where the two holes are) and file out a sort of rectangle for the board to seat inside.

It's not ideal, but it works. I'll end up isolating the board from the metal using kapton tape.

The next step was to machine down the copper piece smaller. Unfortunately, my cutting bit decided to break then and I chewed up the metal. Oh well, it ain't pretty but I guess it still works.

Anyway, I'm waiting to finish this up next week and I'll update you on what happens!

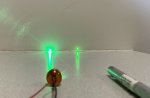

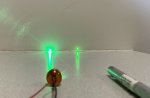

Bonus color shot vs. 532nm dpss:

-Cosmonaut

I had a nice conversation with Immo1282 about his Convoy builds and thought I'd make a little writeup tutorial on how to do it for anyone wondering.

The first thing I did was order a Convoy S2+ host from Mountain Electronics. They're pretty good and their shipping was reasonable in price and time. The blank host is nothing special, it just comes with the end cap, a middle section for a 18650, a top part with a lens, reflector, and pill, and finally some extras in the inside like an extra spring.

Here is the pill and the host. The pill contains a little screw-in retaining ring on the bottom to hold the contact PCB that goes against the battery.

The next step was to order the laser and the driver. I bought the 50mW Osram 520nm diode from DTR's shop, with the driver included in the 20mm casing. Heads up- while the driver he includes is the LDSE500 (a good boost driver), the board is pretty long and I ran in to trouble fitting it in. I would recommend using a round driver like immo1282 did.

The build in immo's thread goes a little like this image he gave me:

As you can see, the aluminum piece should be cut down as much as possible. I can't do this because the driver is too long. The issue with this is that when the whole pill/heatsink assembly is too long, the top of the flashlight can't thread on to the body. I had to desolder the driver from the diode and attach leads on both ends. Since the board is too wide to fit horizontally in the pill, I had to machine out the top (where the two holes are) and file out a sort of rectangle for the board to seat inside.

It's not ideal, but it works. I'll end up isolating the board from the metal using kapton tape.

The next step was to machine down the copper piece smaller. Unfortunately, my cutting bit decided to break then and I chewed up the metal. Oh well, it ain't pretty but I guess it still works.

Anyway, I'm waiting to finish this up next week and I'll update you on what happens!

Bonus color shot vs. 532nm dpss:

-Cosmonaut