rog8811

0

- Joined

- Jul 24, 2007

- Messages

- 2,749

- Points

- 0

I am seeing a number of posts where builders have tried to do all the right things when testing LD's on a proper drive circuit....and then failing by forgetting to short out the capacitor before connecting the LD.

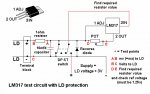

Here is an idea for you...... I have a circuit that I do all of my testing on, it is always knocking around on my workbench should a sudden laser check be required. What makes it different from the circuits I make for final build is that it has:-

A 2 way terminal block for connecting the flying leads from the LD

A series of test points for connecting up the multi meter

And most importantly...

A double pole, single toggle (change over) switch to short out the capacitor and turn off the power

It does what it says, when you turn off the power you short out the capacitor, which means you can safely connect/disconnect LD's without zapping them with the contents of the capacitor.

I hope that helps....

Regards rog8811

Here is an idea for you...... I have a circuit that I do all of my testing on, it is always knocking around on my workbench should a sudden laser check be required. What makes it different from the circuits I make for final build is that it has:-

A 2 way terminal block for connecting the flying leads from the LD

A series of test points for connecting up the multi meter

And most importantly...

A double pole, single toggle (change over) switch to short out the capacitor and turn off the power

It does what it says, when you turn off the power you short out the capacitor, which means you can safely connect/disconnect LD's without zapping them with the contents of the capacitor.

I hope that helps....

Regards rog8811