Sorry, i had seen this before, but had to check one thing, before post.

YES, YOU CAN ..... and with a single slipring, too

..... never heard about overimposed modulation ?

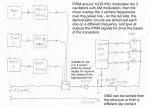

I made a mini-ROV control circuit that, with a single RG58 shielded cable, carry the power, 2 different control signals for the motors, and the video signal in return ..... the key is having multiple frequencies that don't interfer one by the other .....

So you can place the power line (DC), and 3 channels for control the 3 leds (3 different RF modulated signals) in parallel on the same wire, and ofcourse, you have to build the needed circuit on the rotating support for demodulate them and drive individually the leds ..... say, 1, 3 and 7 MHz , AM modulated with PWM signals, probably are separated enough for that use (i had to use more higher frequencies, but that just cause the cable was long ..... you don't need to use 10/12/30MHz signals or power amplifiers)