Berkley Lab | February 1, 2016 | -Written by Paul Preuss | News Release Glenn Roberts Jr. 510-486-5582

Coupling 2 ‘Tabletop’ Laser-Plasma Accelerators, a Decisive First Step Toward Tomorrow’s Ultrapowerful Compact Machines

Berkeley Lab Scientists Create the First-ever, 2-stage Laser-plasma Accelerator Powered by Independent Laser Pulses

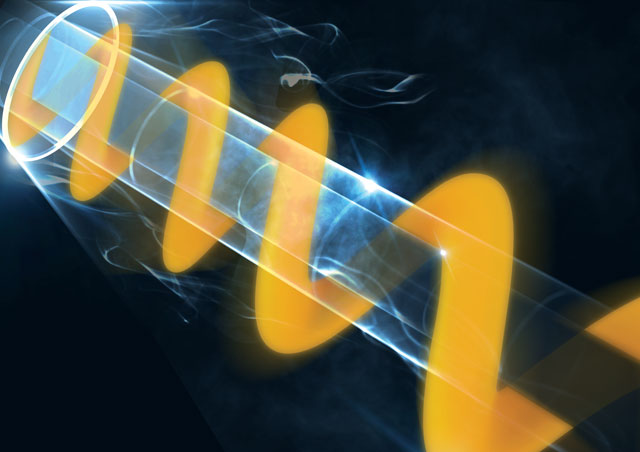

Laser-plasma accelerators (LPAs) got the nickname “tabletop” because, as shown by the unique BELLA accelerator at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab), they can boost electron beams to multibillion electron-volt energies (GeVs) in a few centimeters—a distance thousands of times shorter than conventional accelerators.

Past those few centimeters, however, the laser pulse weakens and energy gain stalls. LPAs will have to get off the tabletop if they are to rival proposed conventional colliders, such as 30-kilometer-long electron-positron linear colliders or circular proton colliders 100 kilometers in circumference, with electron-volt energies in the trillions (TeVs), not billions. Only by coupling a hundred LPAs in series, each powered by a BELLA-class laser in series, and accelerating a well-shaped beam from one stage to the next, will such high energies be achieved.

“Long before planning began for BELLA, we’d set our sights on staging as the way to achieve energies needed for compact particle colliders, free-electron lasers, and other tools of future science,” says Wim Leemans, Director of Berkeley Lab’s Accelerator Technology and Applied Physics Division (ATAP)and Director of the BELLA Center. But because of the daunting technical challenges, including maintaining electron beams with dimensions measured in millionths of a meter and laser pulses measured in quadrillionths of a second (femtoseconds), Leemans says, “Lots of people told us we’d never be able to do it.”

In an experiment packed with scientific firsts, Leemans and his BELLA Center colleagues have now demonstrated that a laser pulse can accelerate an electron beam and couple it to a second laser plasma accelerator, where another laser pulse accelerates the beam to higher energy—a fundamental breakthrough in advanced accelerator science. The results are reported in the Feb. 1 issue of Nature

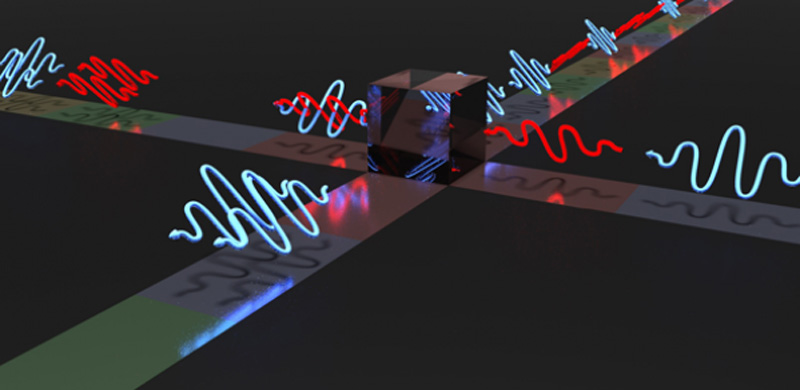

Schematic of the first experiment to achieve staging of laser plasma accelerators (LPAs) with independent laser pulses: a pulse from laser 1 (at left) creates a plasma wakefield in the stage 1 LPA, a gas jet. The resulting electron beam is focused by a capillary-discharge plasma lens and then penetrates a moving tape. Almost simultaneously, an incoming pulse from laser 2 strikes the tape and creates a plasma mirror, which combines the laser beam and electron beam. Entering stage 2, a capillary-discharge LPA, the second laser pulse creates a wakefield in the plasma which further accelerates the electron beam; downstream diagnostics (at right) measure the beam.

Stable Beams, Disposable Mirrors

Sven Steinke, lead author of the Nature paper, says that to achieve staging wasn’t about huge energy gains; the challenge was handing off a useful beam. “A billion electron-volts wouldn’t matter,” he says. “What mattered was stability,” an experiment that would work reliably for days at a time and many thousands of laser shots. “You don’t want to spend three-quarters of your day tuning your beam injector, with no time left to do an experiment.”

The solution was to use two different kinds of LPA. The more advanced but more finicky type is a discharge capillary, a block of sapphire with a thin horizontal tube through it. Hydrogen gas fills the tube; a potent electrical discharge ionizes it, separating electrons from their nuclei and forming a plasma. Almost instantly this discharge arc heats the plasma and forms a laser waveguide, a cylindrical channel of thinner plasma in the center; the incoming laser pulse drives through it like a speedboat on water, picking up free electrons in its wake and hurling them forward like a surfer on a following wave.

A critical challenge was how to introduce the second laser pulse, using a mirror, within the few-millimeter space between the two stages. The electron beam would have to pass through a hole in the mirror. The reflected laser pulse would come close behind. Unfortunately, to focus enough power to accelerate the electron beam, the laser focus would have to be so close to the mirror it would blow it to pieces.

“We decided from the beginning of the project that instead of worrying about blowing up the mirror, we’d blow it up with every shot,” says Leemans. They first developed a prototype mirror of water film, he says, “but settled for much more robust VHS tape.”

Video cassette players may be out of fashion, but VHS tape is thin, stretch-resistant, and capable of running for hours at a time. The electron beam pierces the tape virtually untouched. On the opposite side, in the merest fraction of a second before the laser pulse can penetrate the tape, it ionizes the surface to form a dense, perfectly flat plasma: a highly efficient mirror.

Steinke, whose dissertation involved plasma mirrors and who was a postdoc at the Max Born Institute in Berlin before joining the BELLA Center, characterized the mirror system for the staging experiment. Previous plasma mirrors were based on expensive solid optics made for completely different purposes. Steinke and Leemans agree: “This was the first use of a continuous, high-repetition-rate, disposable plasma mirror.”

A Serendipitous Plasma Lens

The staging system was ready for its first test. In the gas-jet LPA, the first laser pulse created an electron beam that passed through the tape, while the plasma mirror reflected the second laser pulse. Electron beam and laser pulse both entered the stage 2 capillary.

No beam came out.

“We were stunned,” says Jeroen van Tilborg, a long-time member of the BELLA Center and its predecessor, the LOASIS Program, where he earned his PhD from Eindhoven Technical University. “Suddenly there were four or five of us sitting around scribbling on the backs of envelopes.”

ATAP scientists had used discharge capillaries to inject and accelerate electrons for over 10 years, but this was the first time anyone had shot an external electron beam into one. They’d never dealt with the full effects of the powerful discharge current: it ionizes the gas and forms an optical waveguide through the plasma, but also creates a strong magnetic field that can blow apart a pre-existing electron beam.

Or, more optimistically, can shape and focus it. Van Tilborg called dibs on studying the problem and soon realized the pulsed magnetic field would make an excellent plasma lens. Such a fast-acting lens could find many uses, for example by conditioning beams of existing free-electron lasers. Its immediate application was to tightly focus the staging experiment’s injector beam.

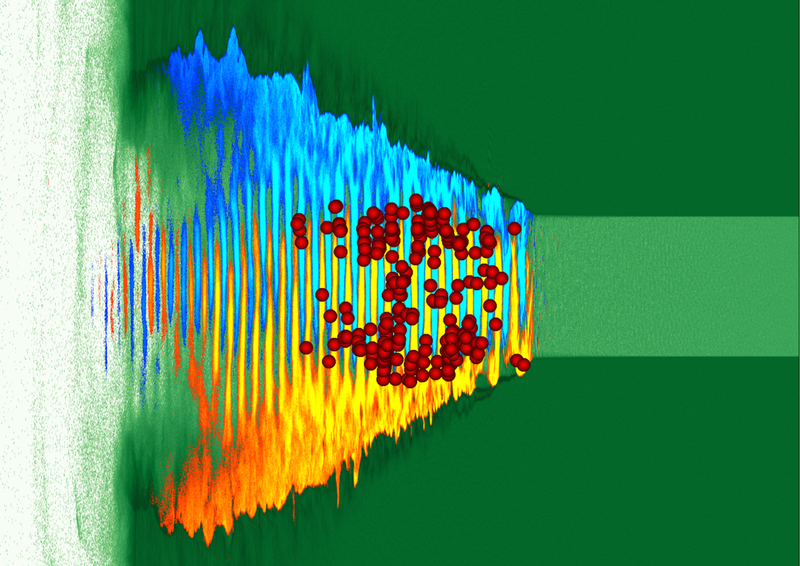

The final configuration—gas-jet injector, plasma lens, plasma mirror, discharge capillary second stage, and diagnostics—showed energy gains, for significant portions of the electron beam, of around a hundred million electron-volts.

The success of the experiment resulted from on-the-job discoveries plus continuous feedback between experimental observations and computer modeling. Running on a Cray supercomputer at DOE’s National Energy Research Scientific Computing Center (NERSC) at Berkeley Lab, the highly efficient INF&RNO code for modeling laser and plasma interactions could turn a day’s experimental data into a simulation almost overnight, like “dailies” on a movie set. Among many other questions, intricacies of laser timing could be explored; focusing the energetic but ragged beam from the gas jet could be simulated even as the serendipitous discovery of how to actually do it was becoming a reality.

“We’re ready for staging BELLA,” says Leemans, using two charge-capillary LPAs. “We’ll split the BELLA laser beam,” capable of a quadrillion watts (a petawatt) per 40-femtosecond pulse every second. “The first stage should bring up the beam to about 5 GeV. We will do the bunch transport with our capillary lens and play around with the timing of the second pulse. We should come out of the second stage with 10 GeV. And, while in the staging experiment we’re only trapping about three or four percent of the electrons available, in BELLA we’ll be able to trap 100 percent of the charge.”

Even better, says Steinke, “BELLA is much simpler. The effects of the tape on beam quality should be much less, and the beam is much ‘stiffer,’ easier to handle.”

Van Tilborg concurs: “At 5 GeV per stage there may be no problem. The higher energy saves you.”