Fiddy

0

- Joined

- May 22, 2011

- Messages

- 2,732

- Points

- 63

G'day,

Its been a very long time since ive returned to this forum, theres been large leaps and bounds in output power since I was here last!

My other hobby (hunting) has led me back here, as hunting at night has me using darker red lasers for spotting feral game as they either cant see it or a confused by it.

I built a 770mW 670-690nm back in 2012 utilizing a T03 package diode and plonked it in a big hand held:

https://laserpointerforums.com/threads/ultrafire-uh-t60-to-3-670-690nm-class-4-handheld.77117/

I havent seen many powerful 670nm+ diodes lately?

There has been some interest among my mates that we should utilise a few red lasers defocused for scanning hills covering a largish area, mainly for locating foxes, this will be mounted on a offroad veichle.

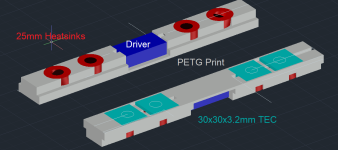

So ive come up with bit of a design to drive 4x ML562G84 2.5W diodes in series, their multimode angle is kind of perfect for scanning hills, I plan on angling 2 diodes facing straight out the front and the outer 2 diodes 20degress to the sides.

Ive purchased a cheap 10" light bar and am in the process of desiging and printing a holder for some heatsinks, and depending on the duty, TECs under each heatsink to transfer heat to the light bar body.

My questions are, what lens would be most suited for this? Generally back in the day i would use a G2, im not going for beam quality of a 3 element glass so thats out, would it be worth using a G8? Are they the best for transmittance of 638nm

Would the clear plastic cover over the light bar melt at ~2W passing through?

Cheers, Fiddy.

Its been a very long time since ive returned to this forum, theres been large leaps and bounds in output power since I was here last!

My other hobby (hunting) has led me back here, as hunting at night has me using darker red lasers for spotting feral game as they either cant see it or a confused by it.

I built a 770mW 670-690nm back in 2012 utilizing a T03 package diode and plonked it in a big hand held:

https://laserpointerforums.com/threads/ultrafire-uh-t60-to-3-670-690nm-class-4-handheld.77117/

I havent seen many powerful 670nm+ diodes lately?

There has been some interest among my mates that we should utilise a few red lasers defocused for scanning hills covering a largish area, mainly for locating foxes, this will be mounted on a offroad veichle.

So ive come up with bit of a design to drive 4x ML562G84 2.5W diodes in series, their multimode angle is kind of perfect for scanning hills, I plan on angling 2 diodes facing straight out the front and the outer 2 diodes 20degress to the sides.

Ive purchased a cheap 10" light bar and am in the process of desiging and printing a holder for some heatsinks, and depending on the duty, TECs under each heatsink to transfer heat to the light bar body.

My questions are, what lens would be most suited for this? Generally back in the day i would use a G2, im not going for beam quality of a 3 element glass so thats out, would it be worth using a G8? Are they the best for transmittance of 638nm

Would the clear plastic cover over the light bar melt at ~2W passing through?

Cheers, Fiddy.