- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

Hello forum.

This time I returned to illustrate You how I learned during this months about the wonderful pyrotechnical world.

The following procedure is the result of many different techniques that I have learned surfing many forums over internet,

and with the help of a great friendly and disposable user named NeighborJ from APC forum.

Of course I have also added something of my own

Here is the needed tools for the whole procedure:

1. A ballmill (or modified rock thumbler);

2. 100x 1cm brass balls media;

3. An hydraulic press;

4. A star plate;

5. 8 and 20 mesh woven wires;

6. A pot and a big spoon;

7. A minipimer.

8. A large sheet of waxed canvas.

Here is chems needed:

1. Potassium nitrate: 400 grams;

2. Pine charcoal: 80 grams;

3. Sulfur: 52,2 grams;

4. Dextrin: 21,2 grams;

5. Demineralized water: 200 ml;

6. Ethyl alcohol.

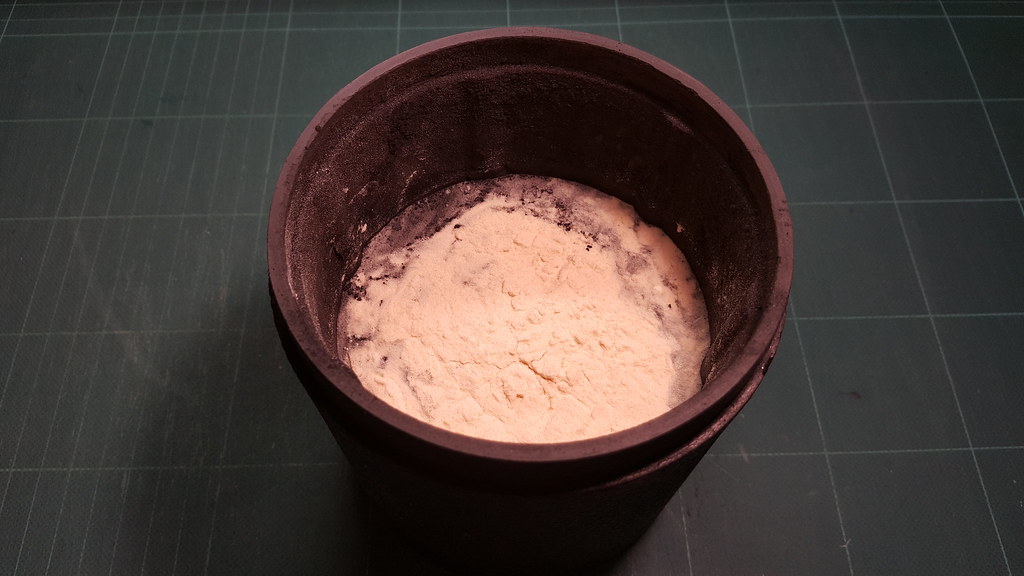

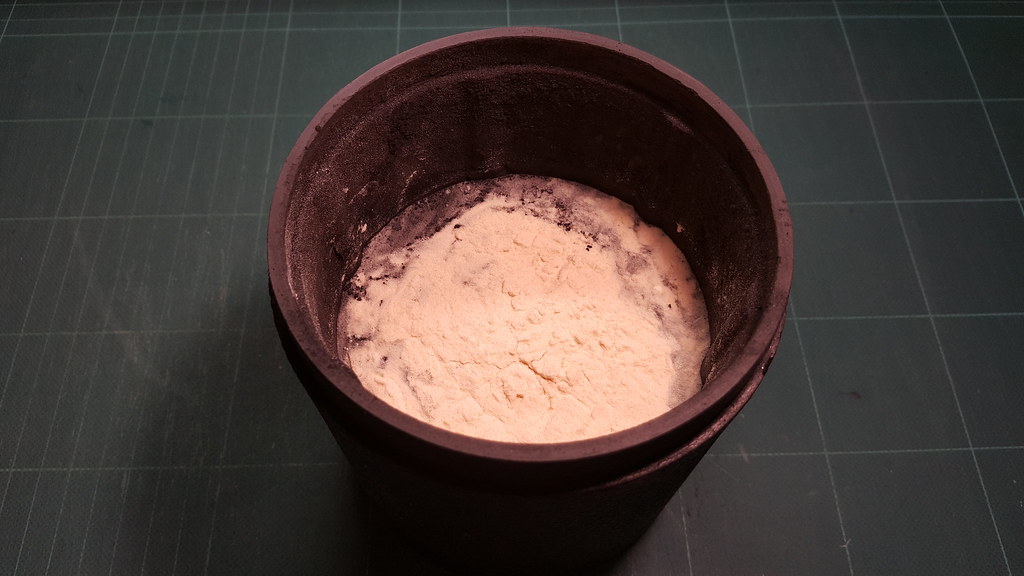

First of all the pine charcoal, the sulfur and the dextrin must be ballmilled all together:

With the correct medias size, the correct number of medias, the correct barrel diameter size, the correct rotation speed and the barrell half-filled,

1 hour is usually more than enough.

Now it is necessary to boil the demineralized water into a pot. Large pot is recommended.

Important: first wait until the water is boiling, then dump the potassium nitrate into the water. Do not use KNO3 with anticaking, it will slow a lot the

BP performance!

Gently mix the water+KNO3 with a spoon (stainless steel or silicone items are preferable) until the water will boil again.

At this point the KNO3 should be completely dissolved:

Dump the ballmilled mix into the hot water+KNO3:

It will be very difficult to dissolve the dry mix in hot water containing KNO3, so please be patient and stir and squeeze the powder

until it looks like a dense paste.

It is advisable to do this step outside, because a lot of charcoal powder can float in the air:

Now, with the help of a minipimer, the wetted BP can be transformed into a very fine, uniform and velvety matter:

While using the minipimer, a little spray of ethilic alcohol will reduce the surface tension and help the mix to dry fastest.

Do not exceed with alcohol or the KNO3 will precipitate.

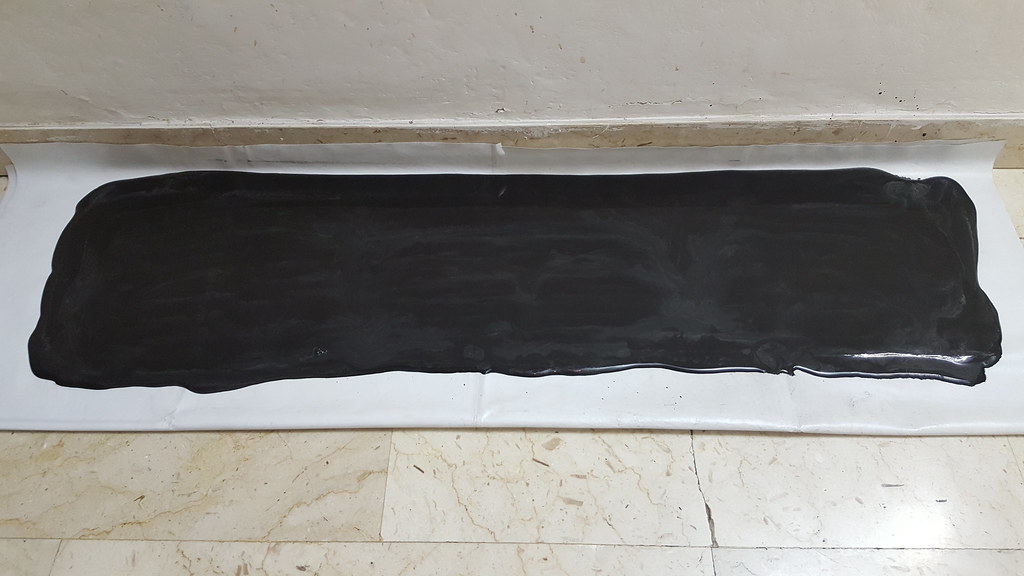

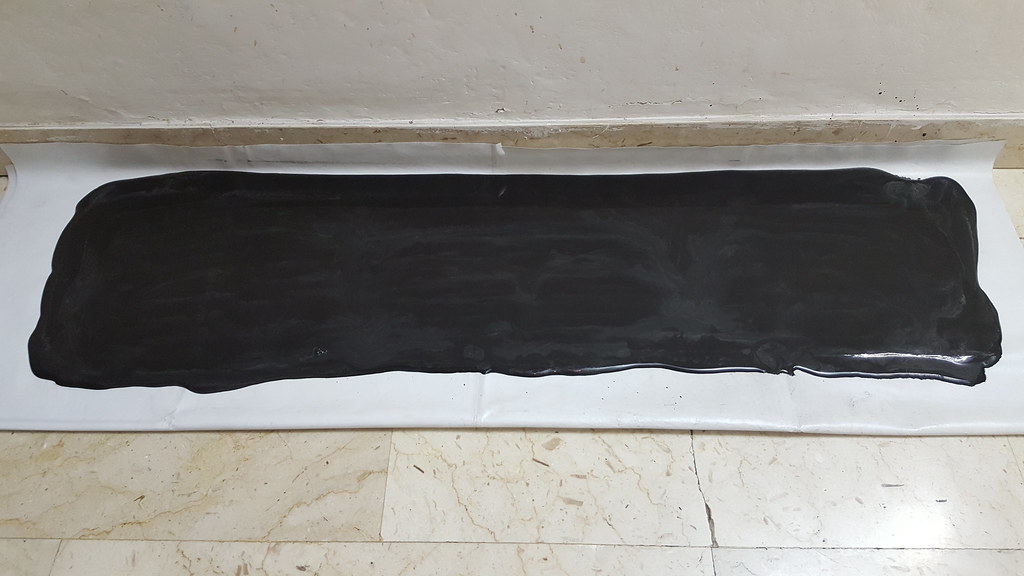

The mixture is spread over a long sheet of waxed canvas:

It is important to leave the mix about 24 hours to let dry them enough. It is advisable to not put the mix near heat sources, or the potassium nitrate try

to recrystallize on surface. Anyway, very few and tiny crystals of recrystallized KNO3 can be visible on mix surface after 24 hours.

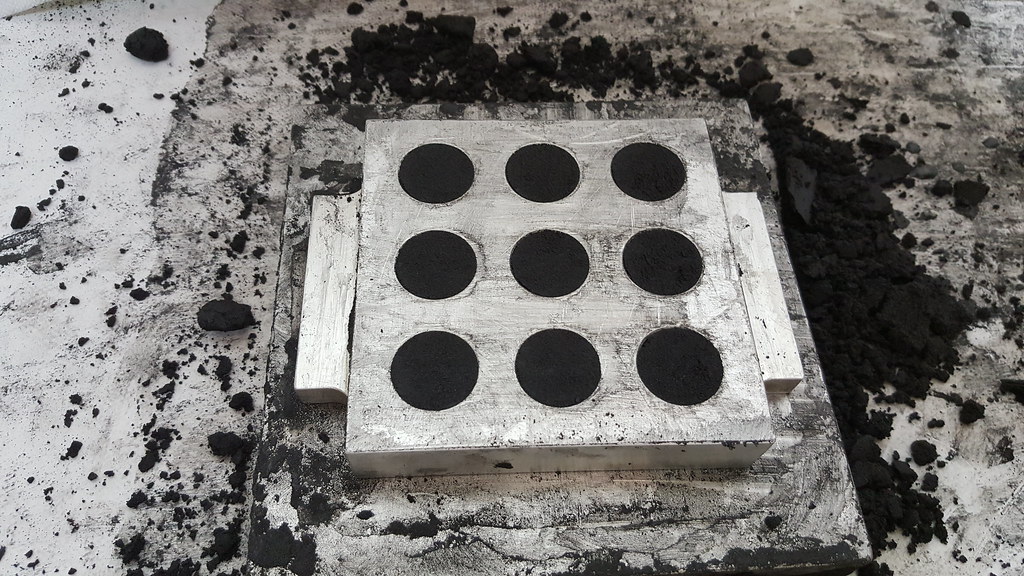

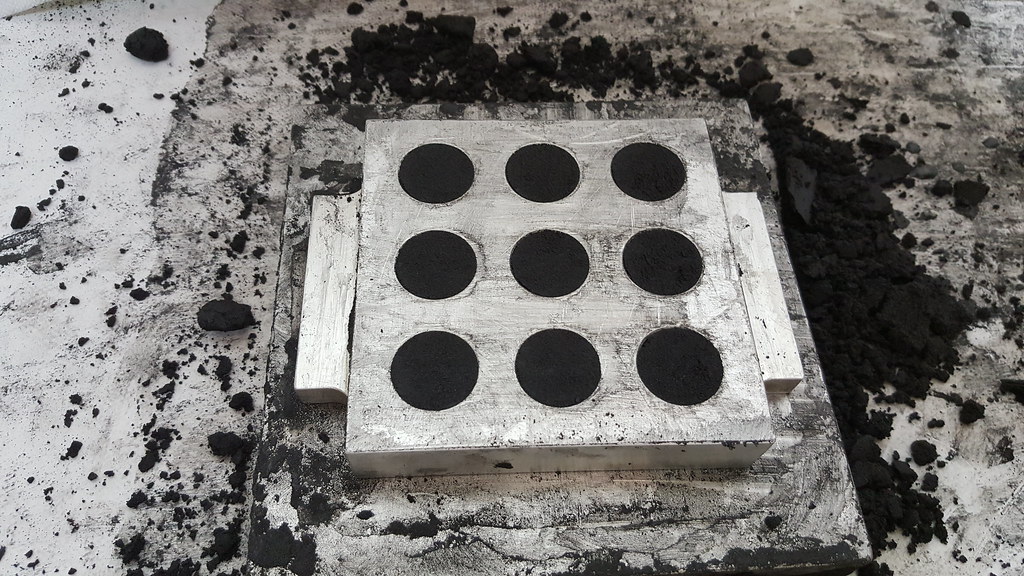

After 24 hours the mix is dry enough to be pressed:

Pressing the mix with the help of a star plate with a pressure of 2 tons:

The few water in excess will be squeezed away while the chems particles will be mixed more intimately.

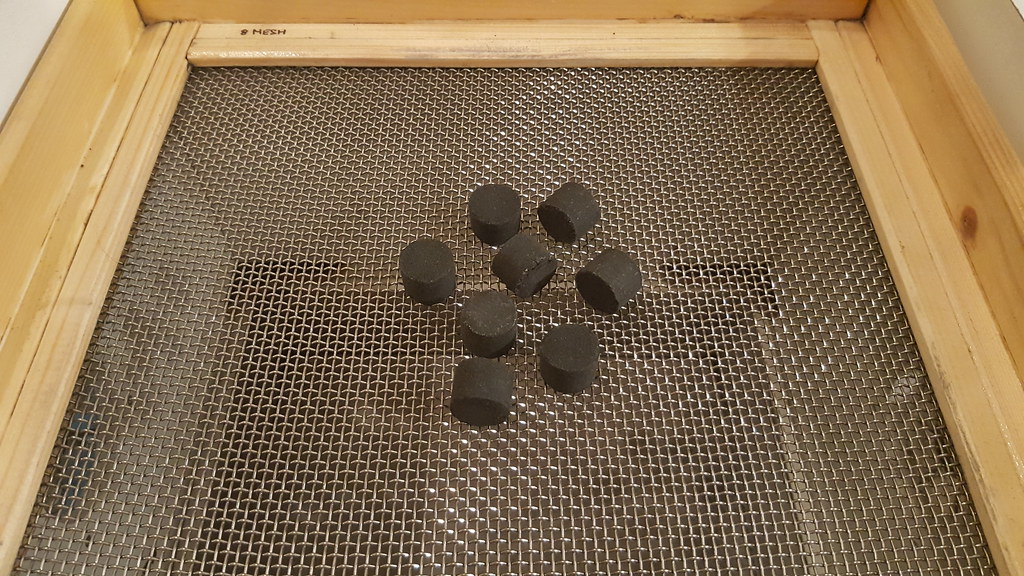

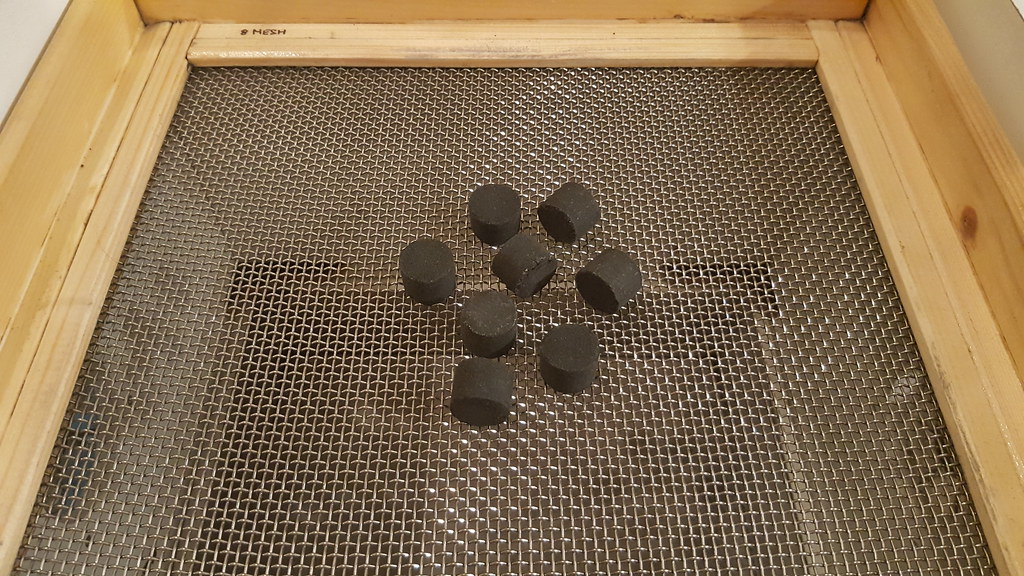

These are the BP cylinders ready to be granulated:

With the help of my precious multipurpose device the BP cylinders will be granulated.

The upper woven wire is 8 mesh while the internal woven wire is 20 mesh.

The finest powder (the so called "meal") will be collected inside the drawer:

To obtain as much as possible 8 mesh powder and few meal it is better to not "scratch" the

cylinders against the woven wire, but rather press the cylinders while moving them in one direction.

The quantity of each powder depends how much dried were the cylinders:

in fact a cylinder too wet will create granules that tends to stick agains one to another, while a cylinder too dry

will create much meal and very few granules. This is a classic "try and error" procedure.

The powders are ready to be dried:

Here is the granulated BP completely dried:

Now the BP is extremely flammable and will be treated with the utmost care and attention.

The powders are placed in two different hermetic containers with silica gel bags and an indicator for moisture levels:

That's all!

Tomorrow I will post a video showing the +8 BP while burning. Outdoor, of course

See ya soon for another nice tutorial!

Richard.

This time I returned to illustrate You how I learned during this months about the wonderful pyrotechnical world.

The following procedure is the result of many different techniques that I have learned surfing many forums over internet,

and with the help of a great friendly and disposable user named NeighborJ from APC forum.

Of course I have also added something of my own

Here is the needed tools for the whole procedure:

1. A ballmill (or modified rock thumbler);

2. 100x 1cm brass balls media;

3. An hydraulic press;

4. A star plate;

5. 8 and 20 mesh woven wires;

6. A pot and a big spoon;

7. A minipimer.

8. A large sheet of waxed canvas.

Here is chems needed:

1. Potassium nitrate: 400 grams;

2. Pine charcoal: 80 grams;

3. Sulfur: 52,2 grams;

4. Dextrin: 21,2 grams;

5. Demineralized water: 200 ml;

6. Ethyl alcohol.

First of all the pine charcoal, the sulfur and the dextrin must be ballmilled all together:

With the correct medias size, the correct number of medias, the correct barrel diameter size, the correct rotation speed and the barrell half-filled,

1 hour is usually more than enough.

Now it is necessary to boil the demineralized water into a pot. Large pot is recommended.

Important: first wait until the water is boiling, then dump the potassium nitrate into the water. Do not use KNO3 with anticaking, it will slow a lot the

BP performance!

Gently mix the water+KNO3 with a spoon (stainless steel or silicone items are preferable) until the water will boil again.

At this point the KNO3 should be completely dissolved:

Dump the ballmilled mix into the hot water+KNO3:

It will be very difficult to dissolve the dry mix in hot water containing KNO3, so please be patient and stir and squeeze the powder

until it looks like a dense paste.

It is advisable to do this step outside, because a lot of charcoal powder can float in the air:

Now, with the help of a minipimer, the wetted BP can be transformed into a very fine, uniform and velvety matter:

While using the minipimer, a little spray of ethilic alcohol will reduce the surface tension and help the mix to dry fastest.

Do not exceed with alcohol or the KNO3 will precipitate.

The mixture is spread over a long sheet of waxed canvas:

It is important to leave the mix about 24 hours to let dry them enough. It is advisable to not put the mix near heat sources, or the potassium nitrate try

to recrystallize on surface. Anyway, very few and tiny crystals of recrystallized KNO3 can be visible on mix surface after 24 hours.

After 24 hours the mix is dry enough to be pressed:

Pressing the mix with the help of a star plate with a pressure of 2 tons:

The few water in excess will be squeezed away while the chems particles will be mixed more intimately.

These are the BP cylinders ready to be granulated:

With the help of my precious multipurpose device the BP cylinders will be granulated.

The upper woven wire is 8 mesh while the internal woven wire is 20 mesh.

The finest powder (the so called "meal") will be collected inside the drawer:

To obtain as much as possible 8 mesh powder and few meal it is better to not "scratch" the

cylinders against the woven wire, but rather press the cylinders while moving them in one direction.

The quantity of each powder depends how much dried were the cylinders:

in fact a cylinder too wet will create granules that tends to stick agains one to another, while a cylinder too dry

will create much meal and very few granules. This is a classic "try and error" procedure.

The powders are ready to be dried:

Here is the granulated BP completely dried:

Now the BP is extremely flammable and will be treated with the utmost care and attention.

The powders are placed in two different hermetic containers with silica gel bags and an indicator for moisture levels:

That's all!

Tomorrow I will post a video showing the +8 BP while burning. Outdoor, of course

See ya soon for another nice tutorial!

Richard.

Last edited: