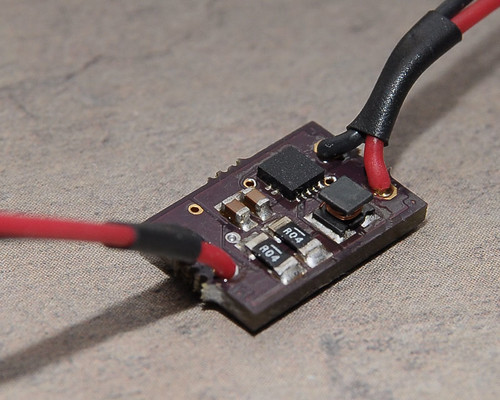

To make a constant current source you put a small resistor in series with the load and measure the voltage across it. More current means more voltage across the resistor, so you use that to determine the current flow and thus cut-out point. That thing that gets hot in the flexdrive, that's a current shunt resistor.

Sorry for the double post, I thought I clicked the edit button...

Sorry for the double post, I thought I clicked the edit button...

Last edited: