- Joined

- Jul 10, 2015

- Messages

- 13,093

- Points

- 113

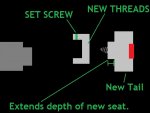

You could send in the copper ring and have a new tail cap made that will slip over the battery tube end like the copper ring did ( In place of the copper ring ) and fasten with a set screw, you would lose the copper ring though but you would not have to mail back and forth the entire host, just ring.

Actually you could measure the dia. of that shank that the copper ring goes around and simply have a tail cap made to fit around it and secure via set screw.

Hopefully someone with a lathe can help whatever you decide to do, good luck.

Actually you could measure the dia. of that shank that the copper ring goes around and simply have a tail cap made to fit around it and secure via set screw.

Hopefully someone with a lathe can help whatever you decide to do, good luck.