- Joined

- Jun 22, 2011

- Messages

- 2,431

- Points

- 83

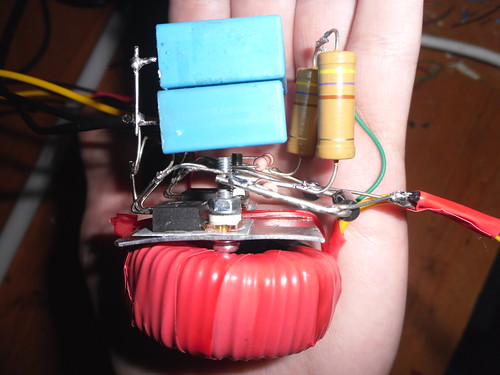

Found this post and the most common advice is to put a 10 W 10 Ohm resistor between +5V and GND.

I've found a tutorial saying PSUs made after 2003 should instead be hooked with a 22 Ohm resistor on the +12V line instead.

I'm also starting to suspect the wires may be too thin. I used 20AWG wire to hook it up.. Do I need to replace it?

Edit: Le Quack posted before I finished editing, ignore this

I've found a tutorial saying PSUs made after 2003 should instead be hooked with a 22 Ohm resistor on the +12V line instead.

I'm also starting to suspect the wires may be too thin. I used 20AWG wire to hook it up.. Do I need to replace it?

Edit: Le Quack posted before I finished editing, ignore this

Last edited: