Tricky trick

: if you're using the 1117 ONLY as current regulator, you can use it connecting it in "reverse" on the negative wire (but careful,

ONLY as current regulator, and only well insulated from anything other) ..... anyway, i really don't see the point in made a host case-positive for a BR

BTW, 1117 can give til 1,5A max, 1A normal work, but the model that you have linked is a TO252 SMD case one, is better to keep the current for this case not over 700 / 800 mA, if not well heatsinked, otherwise it reach easily the thermal limit, and the protection turn it off.

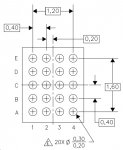

And, i don't want to seem rude, but have you looked at flexdrive schematic ? It's a boost converter used as current regulated driver, using a TPS63010 IC ..... this IC is a DSBGA package, the maximum dimensions of it are 2,65x2,25mm, and have 20 pins in grid configuration (these are the sizes and spaces of the pins, in millimeters)

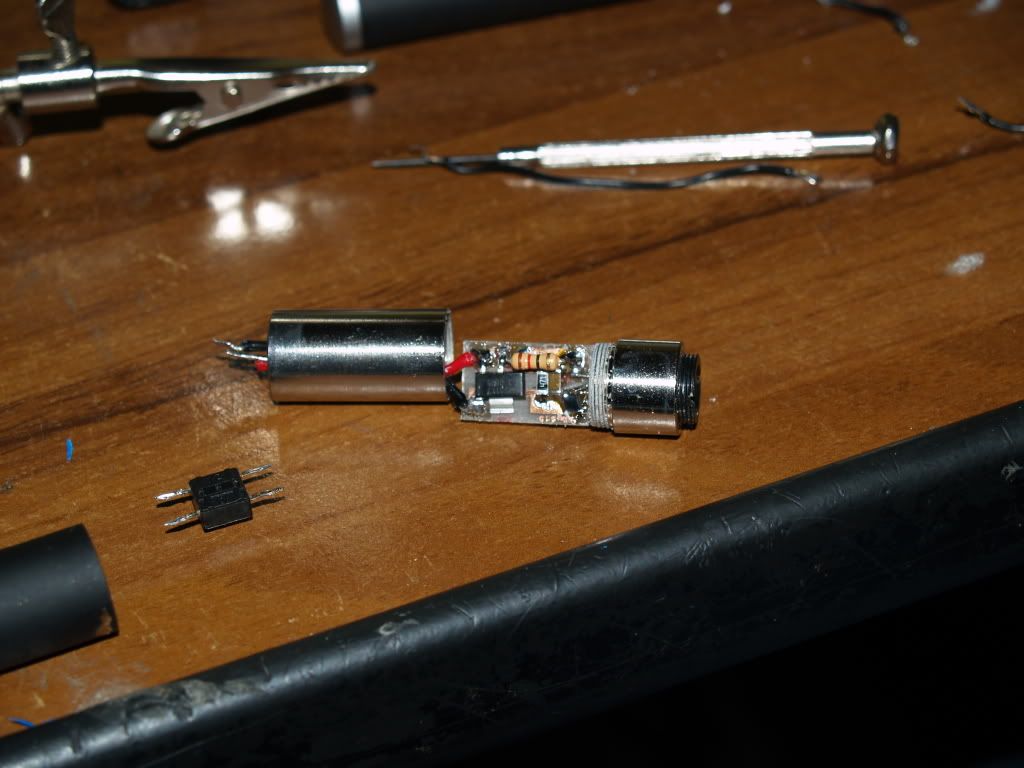

If you can find someone that can solder it by hands, say me who he is, cause the only time that i tried it, i had to solder mini-wires on it, then solder it on a protoboard, just for do a test, and, i have to admit, also if i'm used to work with smd, i killed one of the 2 samples that i had, just trying to solder the wires on it

Yes, i admit that flexdrive have a price a bit high, but considerate also the need to make it industrially with automated machines (and considerate also the possible rejects from the working line), it's high, but not exagerate, after all