I purchased a blackbuck 8m driver for a NUBM44-81 diode (7W).

I will probably not run to the upper power limit, but the intended application is a homebrew laser engraver, so it will likely be on for long enough that a heat sink on the driver would be prudent. I have space and cooling air available.

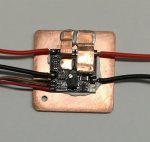

I have seen one recommendation for a 14mm heat sink on the "bottom" of the driver, but this doesn't make much sense to me - it seems like it should be attached directly to the regulator chip. The thing I like about the bottom is that it will be easier to keep it in front of the cooling fan while still potentially keeping reasonable access to the current limit adjustment pot, but don't want to cook it while cooling the wrong part of the device.

Anyway, any advice or success story regarding a robust cooling solution would be much appreciated.

I will probably not run to the upper power limit, but the intended application is a homebrew laser engraver, so it will likely be on for long enough that a heat sink on the driver would be prudent. I have space and cooling air available.

I have seen one recommendation for a 14mm heat sink on the "bottom" of the driver, but this doesn't make much sense to me - it seems like it should be attached directly to the regulator chip. The thing I like about the bottom is that it will be easier to keep it in front of the cooling fan while still potentially keeping reasonable access to the current limit adjustment pot, but don't want to cook it while cooling the wrong part of the device.

Anyway, any advice or success story regarding a robust cooling solution would be much appreciated.