Hello forum. My project was to make a small 1w laser cutter for making solder paste masks, and possibly etching PCBs, etc.

I had ordered this kit this ebayer had, but as it was my first foray into lasers, I may have made some mistakes.

445 Blue 1 Watt Laser Diode Parts Kit | eBay

I tried to exercise static prevention as well as I could. I didn't have a vice, so I had to press in the diode by "walking" around the end of the diode with some channel lock plyers; but I did so in very slight increments.

When soldering on the leads, I used the briefest of brushes with the iron, then secure heatshrink around the solder joints.

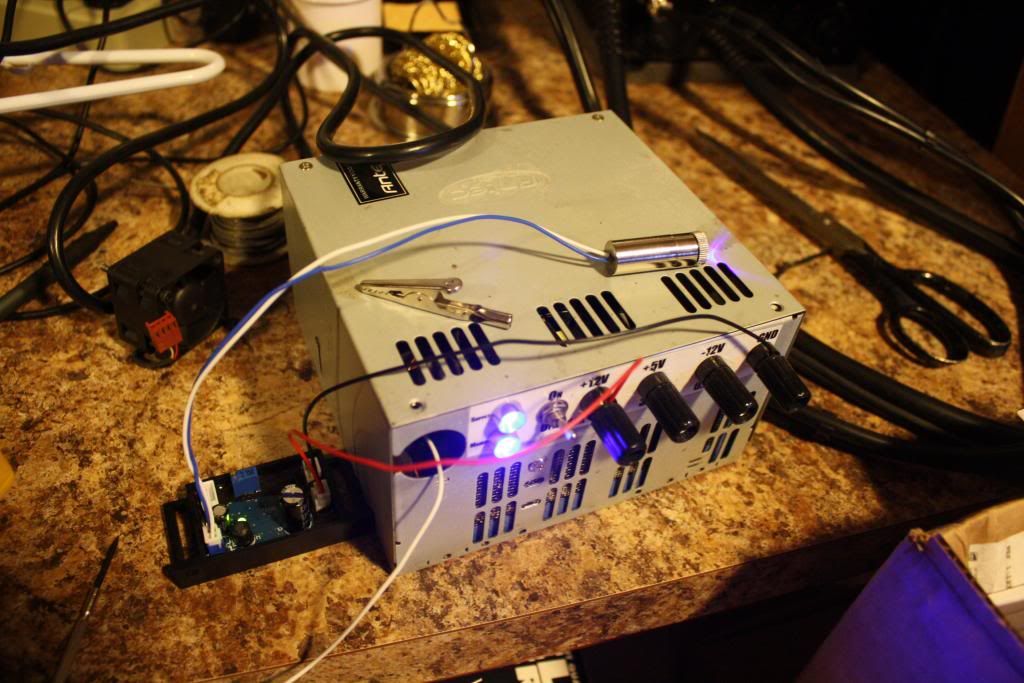

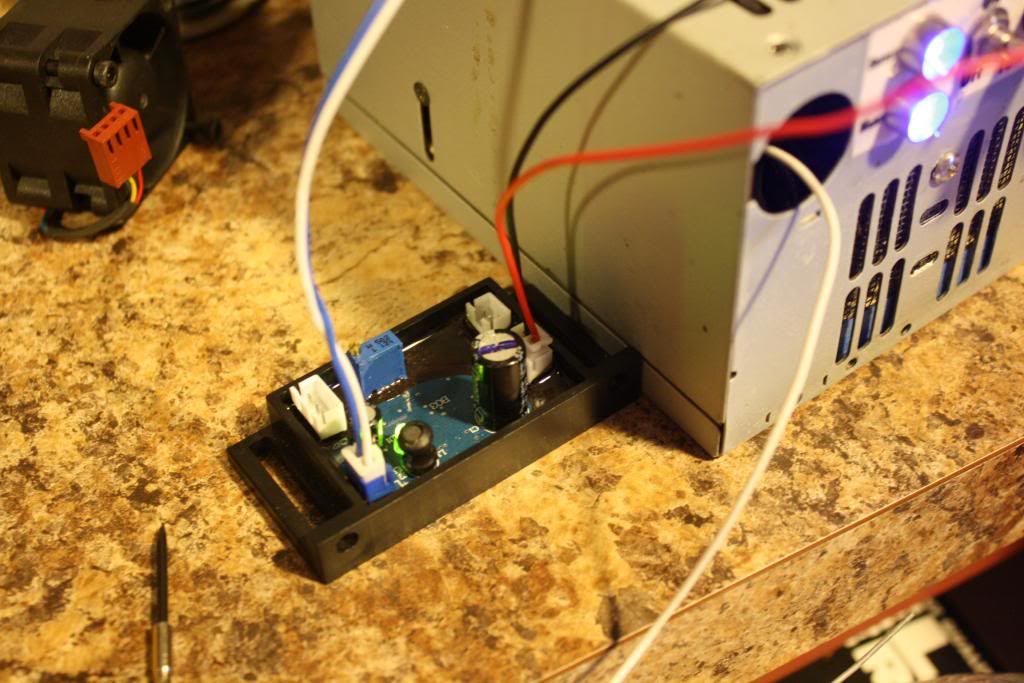

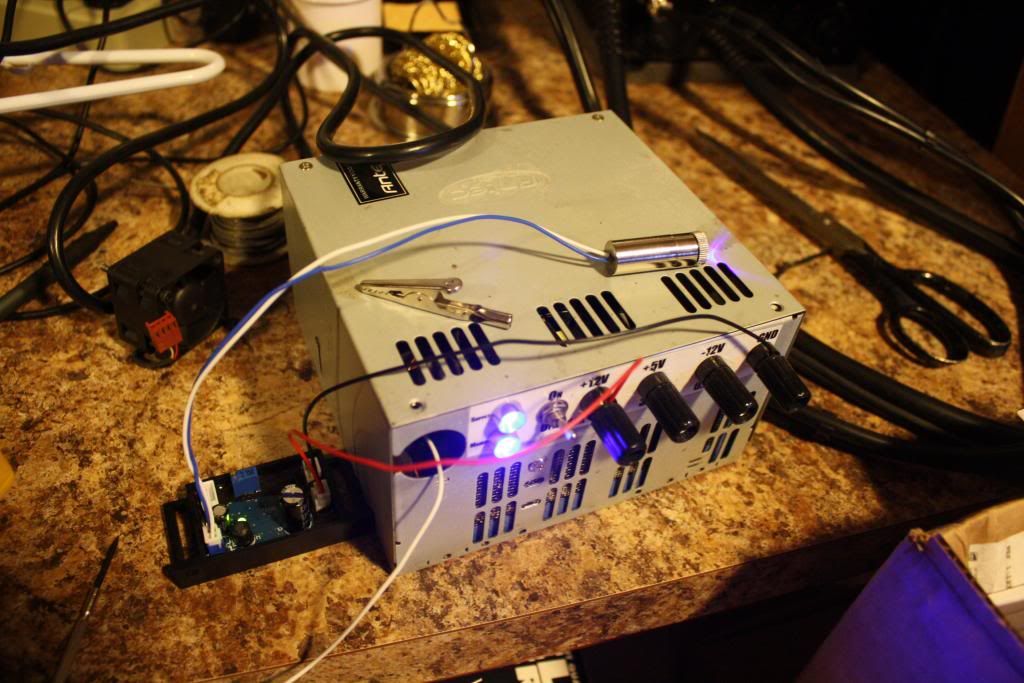

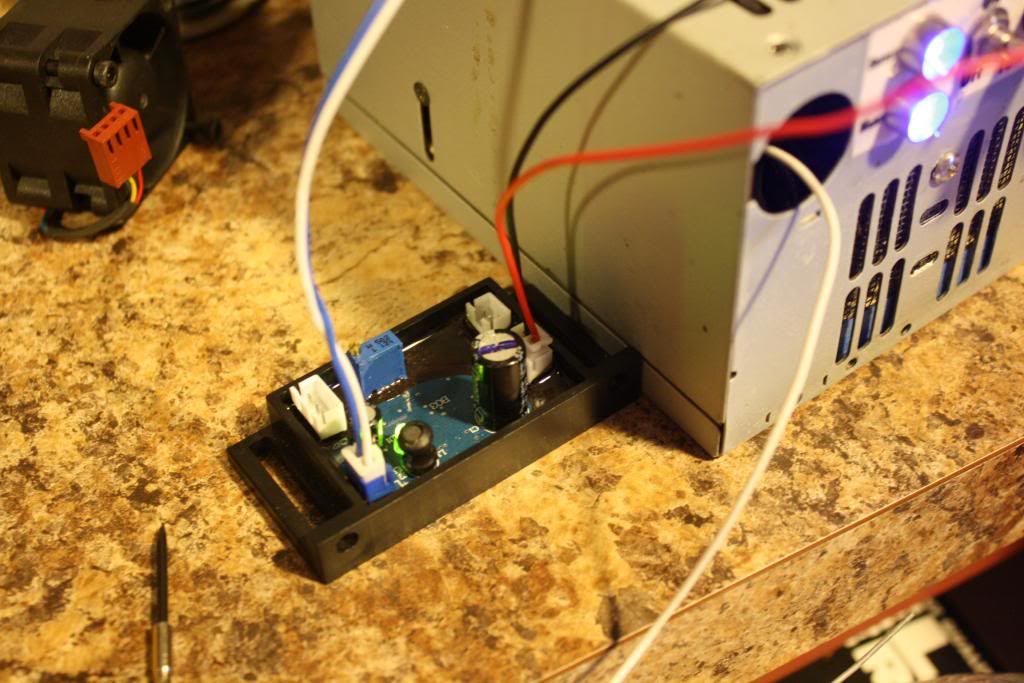

I am using an ATX power supply turned bench supply, so the 12+ source shouldn't be an issue.

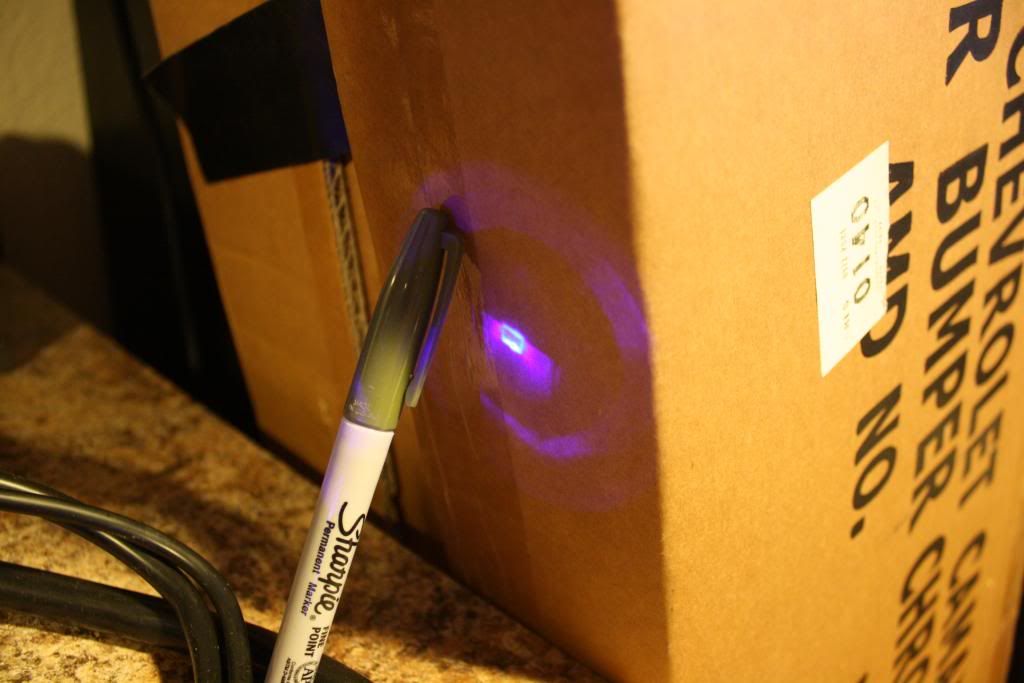

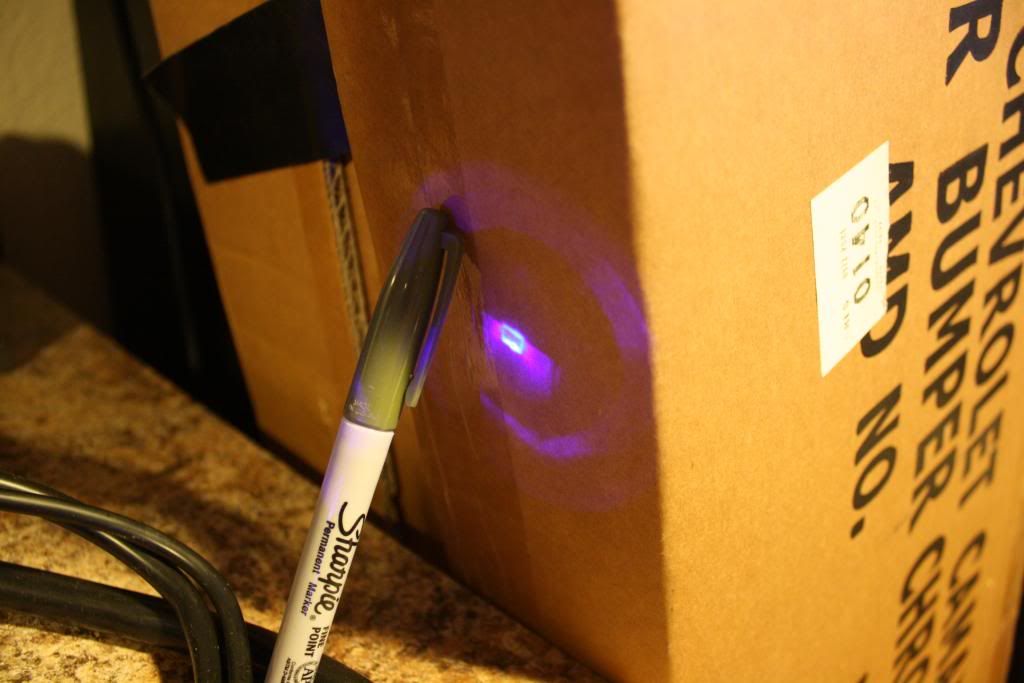

What is an issue is that I'm only getting this little dot of light out of the set up:

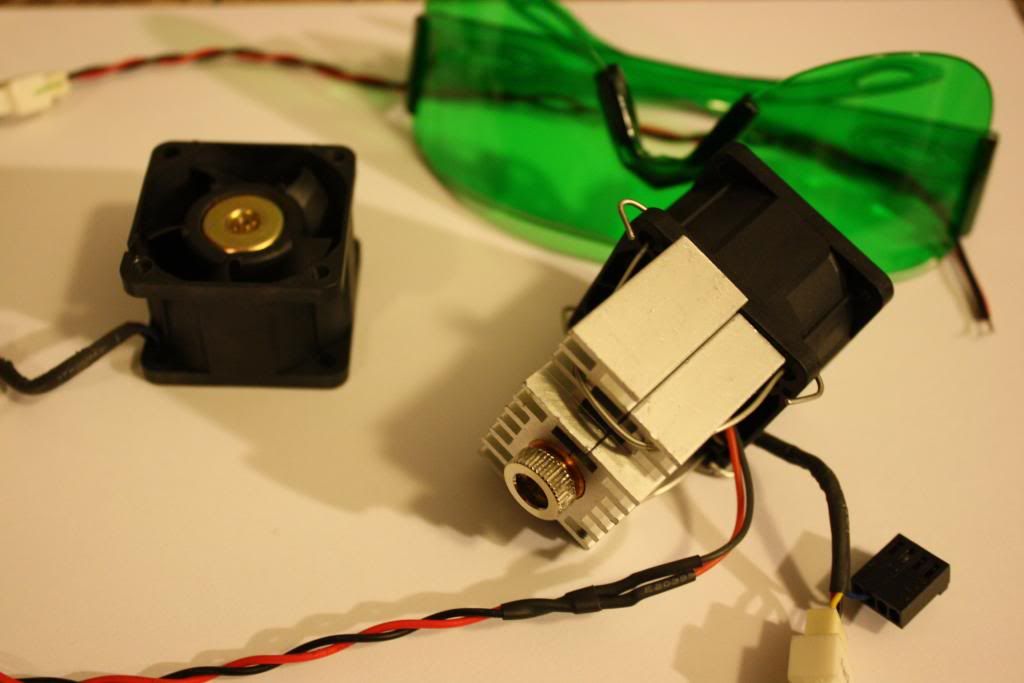

Here's a bit more of what I'm working with:

I tried to find information on what damaged diodes look like, but have been unsuccessful.

I used this pinout as the guide. The short pin is currently not connected to anything.

If anyone thinks there may be a better may to go about adding a laser for etching and cutting (I'd like to be able to eventually cut up to 1/4" acrylic, but I think that's a CO2 laser deal), I'm all ears.

I had ordered this kit this ebayer had, but as it was my first foray into lasers, I may have made some mistakes.

445 Blue 1 Watt Laser Diode Parts Kit | eBay

I tried to exercise static prevention as well as I could. I didn't have a vice, so I had to press in the diode by "walking" around the end of the diode with some channel lock plyers; but I did so in very slight increments.

When soldering on the leads, I used the briefest of brushes with the iron, then secure heatshrink around the solder joints.

I am using an ATX power supply turned bench supply, so the 12+ source shouldn't be an issue.

What is an issue is that I'm only getting this little dot of light out of the set up:

Here's a bit more of what I'm working with:

I tried to find information on what damaged diodes look like, but have been unsuccessful.

I used this pinout as the guide. The short pin is currently not connected to anything.

If anyone thinks there may be a better may to go about adding a laser for etching and cutting (I'd like to be able to eventually cut up to 1/4" acrylic, but I think that's a CO2 laser deal), I'm all ears.