- Joined

- Nov 18, 2009

- Messages

- 253

- Points

- 0

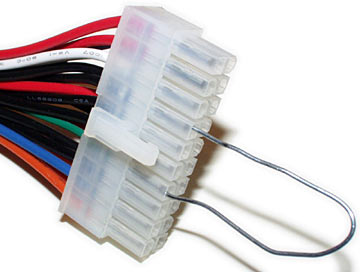

I've seen a few threads and photos on LPF that indicate some people have "converted" an old computer Power Supply Unit to provide power for their DIY laser experiments and lab lasers. I've also seen such a thing explained on the Instructables site.

I'm very interested in seeing if I could "convert" such a PSU into some sort of "lab" power source. I mean, they come complete with a power switch, and cooling fans, too!

If I understand things, those PSU's provide 12v, 5v, and 3.x volts, right? So depending on how much power is needed for a particular application, you'd just plug into the correct jack (or hook up the proper wires, etc)....

BUT, wouldn't you still need either:

1. A driver to provide the proper current (and limit its max) for the LD? Like a RKCSTR, Microdrive, etc? Although these are typically used because of their small size to fit inside a flashlight host, and are attached directly to the LD, correct?

or

2. A further means to "dial in" the proper mA of power going directly to the LD? Almost like a dimmer switch of some sort. This would be a separate component attached or associated with the PSU, not attached to the LD.... Thus allowing a more "universal" source of power without worrying about a specific driver for a specific LD.

How would #2 be accomplished? I mean, as a quick test to see if a harvested LD is even working, couldn't you hook it up (w/ alligator clips) to this variable power source, and start on the low end (25mA) and slowly up the level to 100, 200, etc mA until you see a dot/beam?

You'd probably have to have a built-in meter as well, which indicated exactly how much current is going to the LD.

Isn't this the premise for those store-bought, separate laser power supplies that are used for HeNe lab lasers, etc?? I've seen photos of them which digitally indicate the mA being used to power the particular laser.

I guess even for a "stand-alone" adjustable power source, you'd still basically be using a driver, but it wouldn't be inside a host, but maybe integrated into the PSU box, or as a separate module.

On a side-note (question), are the drivers (like RKCSTR, etc) laid out and built on a small circuit board only because they need to be small to fit inside hosts? Could the same type of driver be built "larger" to fit inside its own case? Kind of like modular laser components (lens holders, mirror holders, etc), where each piece secures onto an aluminum rail system?

Hopefully this all makes some sort of sense. I'm new to electronics so I don't really know the correct terminology. Let me know if I need to clarify or re-word anything.

Thank you for reading, and for any input you can provide.

I'm very interested in seeing if I could "convert" such a PSU into some sort of "lab" power source. I mean, they come complete with a power switch, and cooling fans, too!

If I understand things, those PSU's provide 12v, 5v, and 3.x volts, right? So depending on how much power is needed for a particular application, you'd just plug into the correct jack (or hook up the proper wires, etc)....

BUT, wouldn't you still need either:

1. A driver to provide the proper current (and limit its max) for the LD? Like a RKCSTR, Microdrive, etc? Although these are typically used because of their small size to fit inside a flashlight host, and are attached directly to the LD, correct?

or

2. A further means to "dial in" the proper mA of power going directly to the LD? Almost like a dimmer switch of some sort. This would be a separate component attached or associated with the PSU, not attached to the LD.... Thus allowing a more "universal" source of power without worrying about a specific driver for a specific LD.

How would #2 be accomplished? I mean, as a quick test to see if a harvested LD is even working, couldn't you hook it up (w/ alligator clips) to this variable power source, and start on the low end (25mA) and slowly up the level to 100, 200, etc mA until you see a dot/beam?

You'd probably have to have a built-in meter as well, which indicated exactly how much current is going to the LD.

Isn't this the premise for those store-bought, separate laser power supplies that are used for HeNe lab lasers, etc?? I've seen photos of them which digitally indicate the mA being used to power the particular laser.

I guess even for a "stand-alone" adjustable power source, you'd still basically be using a driver, but it wouldn't be inside a host, but maybe integrated into the PSU box, or as a separate module.

On a side-note (question), are the drivers (like RKCSTR, etc) laid out and built on a small circuit board only because they need to be small to fit inside hosts? Could the same type of driver be built "larger" to fit inside its own case? Kind of like modular laser components (lens holders, mirror holders, etc), where each piece secures onto an aluminum rail system?

Hopefully this all makes some sort of sense. I'm new to electronics so I don't really know the correct terminology. Let me know if I need to clarify or re-word anything.

Thank you for reading, and for any input you can provide.

![Dec2609D200 001 [2].jpg](/data/attachments/13/13501-e4477b913387751389c92ef2b68959dd.jpg?hash=5Ed7kTOHdR)

![Dec2609D200 002 [1].jpg](/data/attachments/13/13502-e218d4a4f80ad11e15b7951c15771bde.jpg?hash=4hjUpPgK0R)