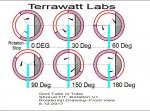

Is it 116.6 degrees because that is what you made it to be, or could it not be 180 degrees with the optics on a ledge down the center of the aluminum tube? If so, then this idea could work...... at least it seems so. Having such a small flat glass window doesn't look as nice as 180 degrees of visual access, but I guess if the flat window is easier, then it is your build.

Well.....with the Cyan Cannon build....we really have no room to put the optics down in a channel....so...they must stay on the flat bridge....which equates to 116.6 degree.

I propose we use a dual tube design....a " Tube in a Tube " concept.

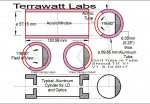

A Main tube machined from Aluminum....with a 116.6 degree slot removed...full length.

Then use an Acrylic tube, same length, thickness and OD/ID. Machine out a chord of 116.6 degree.

The Acrylic section will then be epoxy fixed....into the Aluminum section.

When the degree angles are done correctly....the Acrylic section is " inlayed " into the Aluminum Main tube.....and we have dual construct ....with the same OD and ID.

See the attached drawing. Gort Shroud TIT V1.

Because the openings are beveled/angled...the fit....will be like a keystone geometry. The Acrylic will drop down...so far...and stop. Likely a very thin application of clear epoxy will fix the Acrylic to the Main tube !!!:eg::eg:

The end result will provide a Field Of View (FOV) of 116.6 degree. Not the Full 180....but much improved over the 48.8 degree of the flat glass plate design.

I have a method figured out on how to machine the tube sections. There may be some...er..ahhh..waste pcs as we "transverse the Learning Curve" !!!

So it goes !!

Stay tuned as this continues to unfold....for we are again in " Undiscovered Country "

CDBEAM