RayJay

0

- Joined

- May 2, 2014

- Messages

- 344

- Points

- 0

Hi everyone,

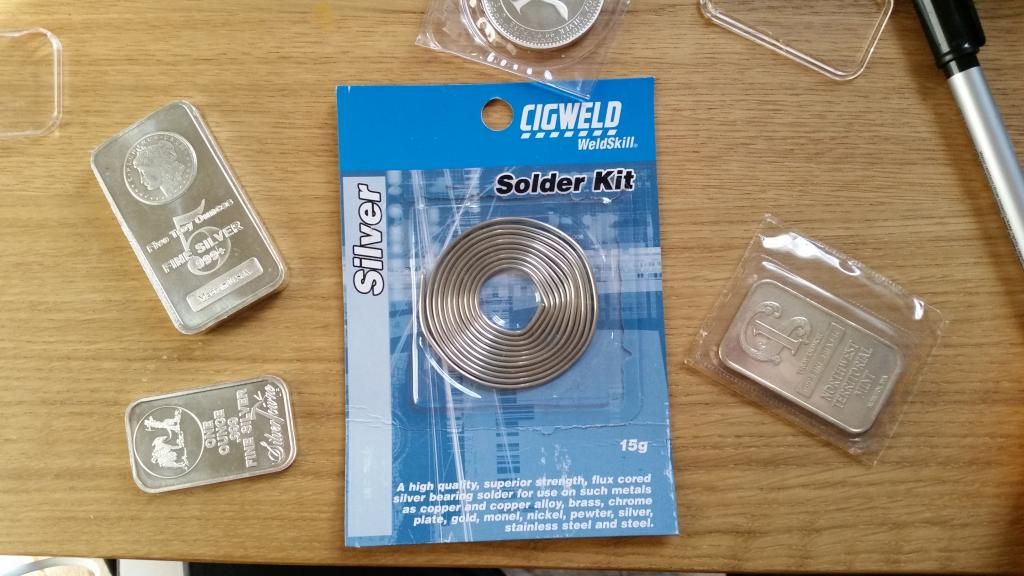

I got a box of this Silver Solder today and want to offer it here.

It is thin enough to fit in an envelope so standard postage to the US and Canada is $3 and Australia is $1.

AUD$5 per 15 Gram Pack.

Pack in the photo is open and has been used so usually there is a few more rings of solder.

I have about 30 of these only and (probably) won't be getting any more. So get them while I have them!!

I got a box of this Silver Solder today and want to offer it here.

It is thin enough to fit in an envelope so standard postage to the US and Canada is $3 and Australia is $1.

AUD$5 per 15 Gram Pack.

Pack in the photo is open and has been used so usually there is a few more rings of solder.

I have about 30 of these only and (probably) won't be getting any more. So get them while I have them!!