Thanks Trevor i will, you do great work for the forum ...hate slow sample rate that's all ...

Ordinarily I'd move discussion over to that thread, but I think since this is an important aspect of design, it's good to have over here too!

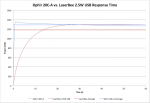

I did a quick test of the same laser on an Ophir 20C-A vs. a LaserBee 2.5W USB. The test duration was 60 seconds and the laser was allowed to completely cool between trials.

I've marked the averages with horizontal lines.

Ignoring the overshoot, the Ophir 20C-A read a peak of 1351mW.

The LaserBee read a peak of 1300mW, but as the sensor continued to warm, this was kicked back down to 1288mW (this knee is, I believe, part of the LaserBees sensor nonlinearity correction). Because of the nature of a knee in the curve, it's difficult to know whether that is a "true" peak or not.

Thus, the LaserBee read (at best) a peak 4% lower than the Ophir 20C-A. Not awful, but it's not exactly a selling point either.

Now, on to the averages.

The Ophir 20C-A averaged 1290mW over the duration of the test.

The LaserBee averaged 1182mW over the duration of the test. The lower value is due to the the amount of time it takes the sensor to respond to the full power of the laser.

The difference is approximately 9% - which backs up what you're saying about a ~10% difference.

Also, note:

Sampling rate should NOT be confused with sensor response time. The LaserBee I used samples at around 17Hz - while the Rubicon samples at just under 10Hz. The "slowness" you see in your LaserBee is due to the high thermal mass of the sensor, not because of a slow sampling rate.

Hope that helps!

Trevor