- Joined

- Nov 2, 2012

- Messages

- 632

- Points

- 43

The other day my laser reflected off the curved window of my toaster oven. The window is a cylindrical section. The dot on the opposite wall was almost circular, so it got me thinking and reading about FAC corrective optics.

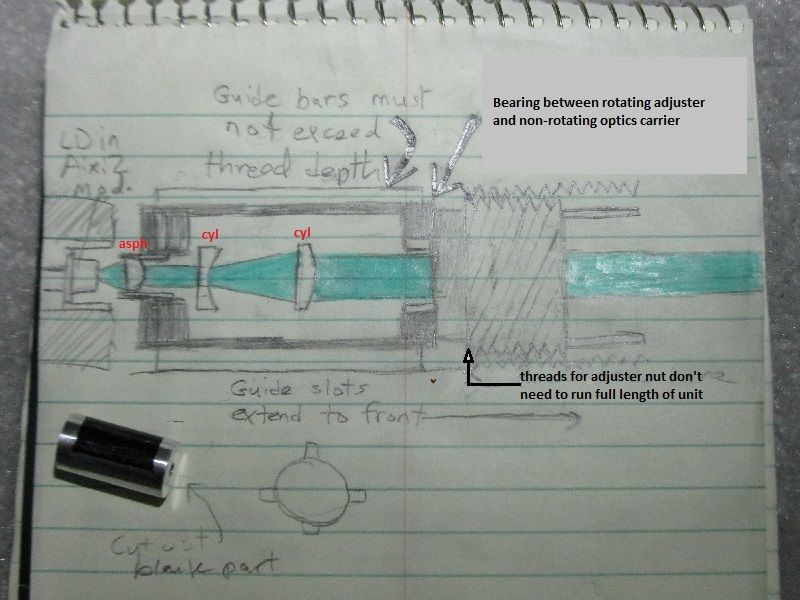

I came up with this today. Do you think it would work?

ETA: Bad picture, too much reflection/glare... have to run now but will take a better one later....

The drawing above is approximately to scale. (about 1.5" by 4.25" at this scale - just a little narrower and it could it into a D-maglite host.) The first lens in the optics train is the G2 in a M9x0.5 barrel, so the drawing is close to scale.

In the design above, it should be possible to change the laser focus by rotating the adjustment nut at the right, without rotating the lens carrier on the left. A bearing separates the lens carrier from the rotating adjuster. The lens carrier unit has guide bars or pegs on it, which ride in slots running along the outer walls, to prevent rotation. The depth of the slots must not exceed the adjuster's thread depth. The slots must cut across the threads so that the lens carrier can be installed or removed.

I don't really like the guide-bar setup. It would prevent rotation but machining the lens carrier with those bars/pegs looks like a PITA. This would need to be improved but I can't think of anything better at the moment.

Rotating the adjuster nut moves it along the threads, and it pushes or pulls the lens carrier as it does so. But due to the bearing, it imparts no rotation to the carrier. The guide slots would probably need grease. None of the optics in this setup would rotate, including the initial G1/G2/aspheric collimator.

The lens carrier is threaded M9x0.5 at the left; that is where your G1/G2 goes. That gives an idea of the scale. To the right of that are the FAC optics. The carrier unit is big because FAC optics are big. The only acylindrical lenses I could find were larger than our usual (G2-sized) lenses. Anamorphic prisms are likewise bulky. A good "general purpose" optics carrier should be big enough to use either.

Plus if you need to FAC your laser chances are it's a big MM so you probably are better off with a bigger host and more heatsinking anyway.

At the far left is the laser diode in the standard AixiZ module, or your own custom heatsink.

To make the carrier I would start with a solid round bar and cut out a big flat section of it, see the AixiZ module back part in the picture. The black part would be cut out - like the slots on Lincoln logs, if you've seen those. Then the apertures would be machined along the central axis. That would give a large flat space for mounting optics, with apertures on each end. The lens carrier would then have a curved (cylindrical) cover that would screw into place and keep dust out of there. The screw lugs would be at the four corners.

The guide bars are the PITA, maybe mount small pegs at each end, which would ride in the slots to keep it from turning? It's a straightforward principle but looks like it would be hard to machine. Maybe something similar to the crosshead in a double-acting steam engine?

Would it work? I think so. Rotating the adjusting nut, which moves the bearing, which moves sliding carrier: focus is changed without rotating the FAC optics. The bearing is the key. It would be cool if there were a "standard" FAC setup, just as the AixiZ module is the standard non-FAC setup.

Interested in seeing what people think... it definitely needs to be refined, but I think it really could work.

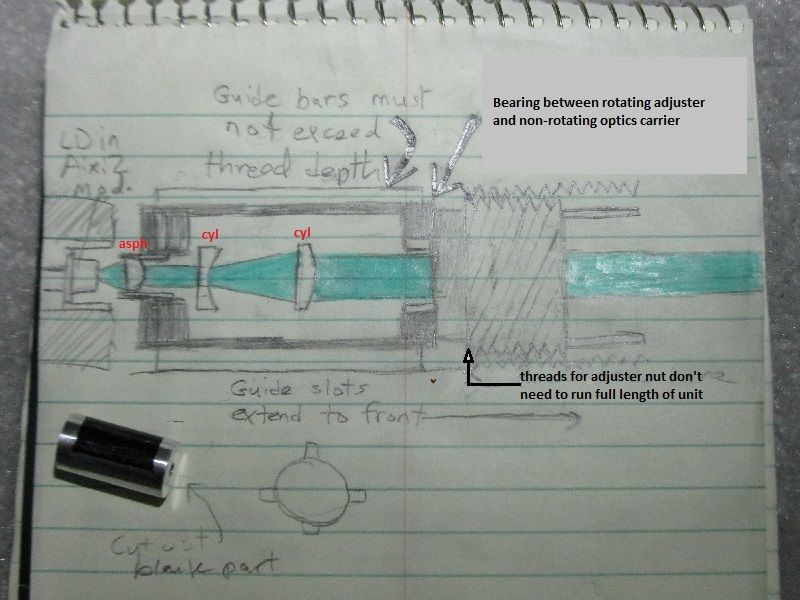

I came up with this today. Do you think it would work?

ETA: Bad picture, too much reflection/glare... have to run now but will take a better one later....

The drawing above is approximately to scale. (about 1.5" by 4.25" at this scale - just a little narrower and it could it into a D-maglite host.) The first lens in the optics train is the G2 in a M9x0.5 barrel, so the drawing is close to scale.

In the design above, it should be possible to change the laser focus by rotating the adjustment nut at the right, without rotating the lens carrier on the left. A bearing separates the lens carrier from the rotating adjuster. The lens carrier unit has guide bars or pegs on it, which ride in slots running along the outer walls, to prevent rotation. The depth of the slots must not exceed the adjuster's thread depth. The slots must cut across the threads so that the lens carrier can be installed or removed.

I don't really like the guide-bar setup. It would prevent rotation but machining the lens carrier with those bars/pegs looks like a PITA. This would need to be improved but I can't think of anything better at the moment.

Rotating the adjuster nut moves it along the threads, and it pushes or pulls the lens carrier as it does so. But due to the bearing, it imparts no rotation to the carrier. The guide slots would probably need grease. None of the optics in this setup would rotate, including the initial G1/G2/aspheric collimator.

The lens carrier is threaded M9x0.5 at the left; that is where your G1/G2 goes. That gives an idea of the scale. To the right of that are the FAC optics. The carrier unit is big because FAC optics are big. The only acylindrical lenses I could find were larger than our usual (G2-sized) lenses. Anamorphic prisms are likewise bulky. A good "general purpose" optics carrier should be big enough to use either.

Plus if you need to FAC your laser chances are it's a big MM so you probably are better off with a bigger host and more heatsinking anyway.

At the far left is the laser diode in the standard AixiZ module, or your own custom heatsink.

To make the carrier I would start with a solid round bar and cut out a big flat section of it, see the AixiZ module back part in the picture. The black part would be cut out - like the slots on Lincoln logs, if you've seen those. Then the apertures would be machined along the central axis. That would give a large flat space for mounting optics, with apertures on each end. The lens carrier would then have a curved (cylindrical) cover that would screw into place and keep dust out of there. The screw lugs would be at the four corners.

The guide bars are the PITA, maybe mount small pegs at each end, which would ride in the slots to keep it from turning? It's a straightforward principle but looks like it would be hard to machine. Maybe something similar to the crosshead in a double-acting steam engine?

Would it work? I think so. Rotating the adjusting nut, which moves the bearing, which moves sliding carrier: focus is changed without rotating the FAC optics. The bearing is the key. It would be cool if there were a "standard" FAC setup, just as the AixiZ module is the standard non-FAC setup.

Interested in seeing what people think... it definitely needs to be refined, but I think it really could work.

Last edited: