- Joined

- Apr 29, 2008

- Messages

- 1,562

- Points

- 48

Edit: After a long and friendly conversation with BobBoyce over Laserchat, it seems the problem was identified. Key points are pasted from the chat log:

(12:23:35 AM) BobBoyce: the oc could just have indium splash on it causing the output malfunction

if you have a reflow station and a good magnifier, it is possible to use a small fine point and reseat the die while reflowing at about 110C

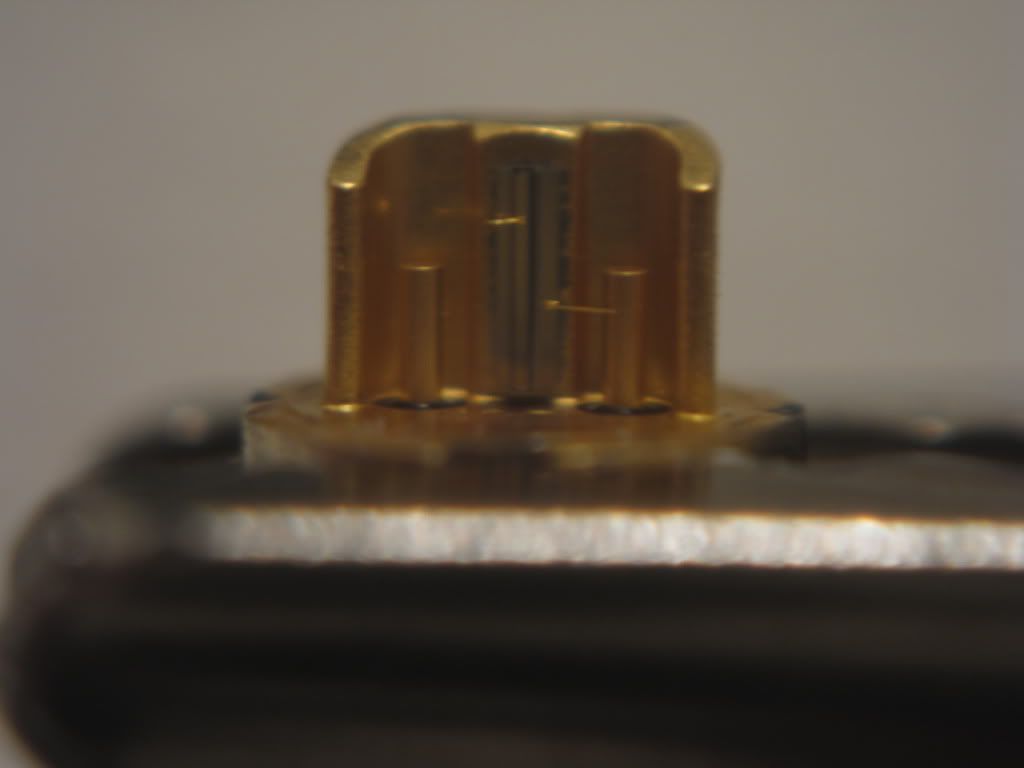

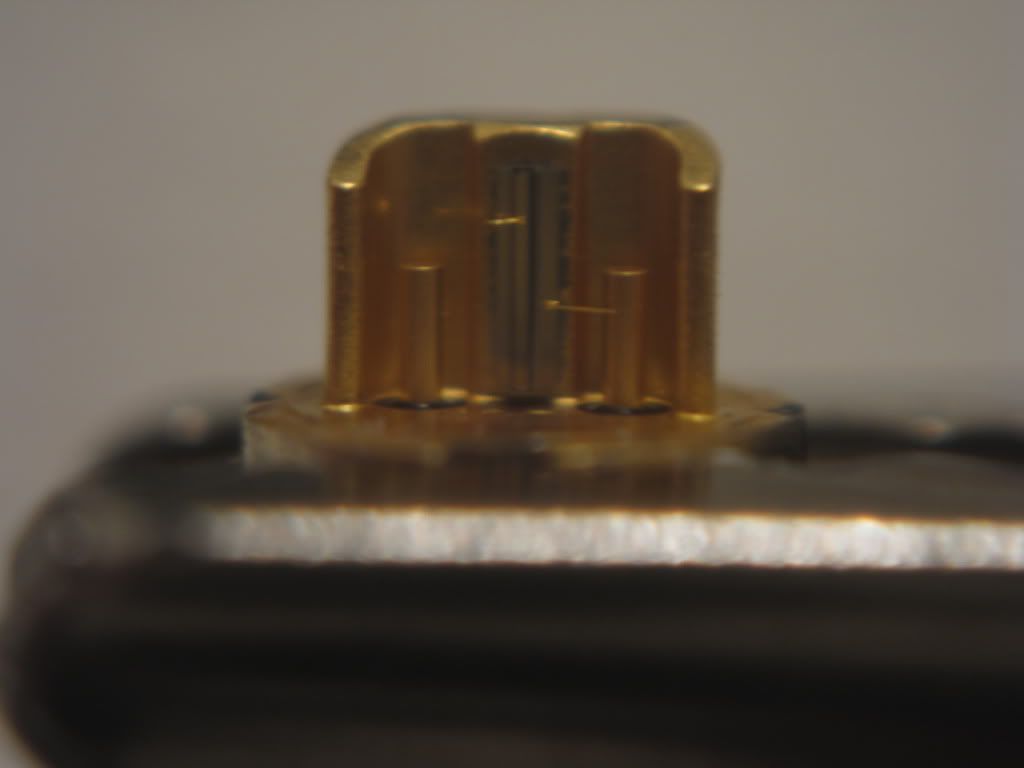

but it can even be seen in the unpowered photo the dark strip of the die side is exposed even when viewed from above

(12:15:07 AM) BobBoyce: if you heat a LD enough the indium will let loose

(12:16:09 AM) BobBoyce: it really does look like mechanical shock damage

(12:14:15 AM) BobBoyce: ok, the optical coating damage would be from too much drive current

(12:11:21 AM) BobBoyce: but the output end of the die appears to be damaged as well

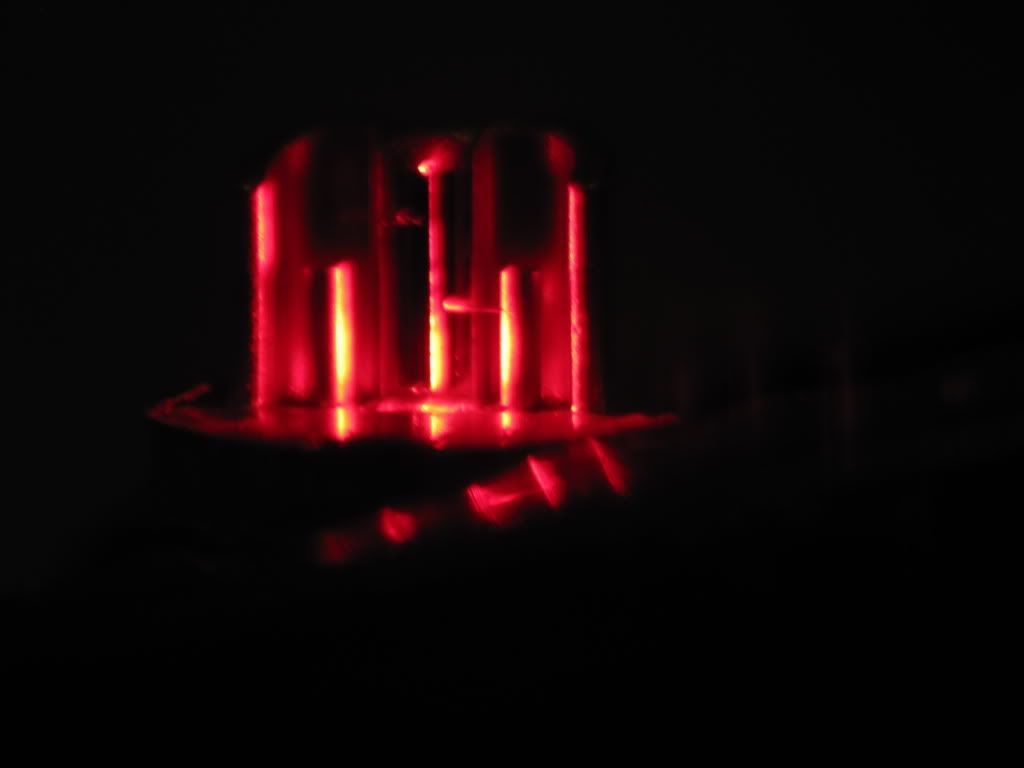

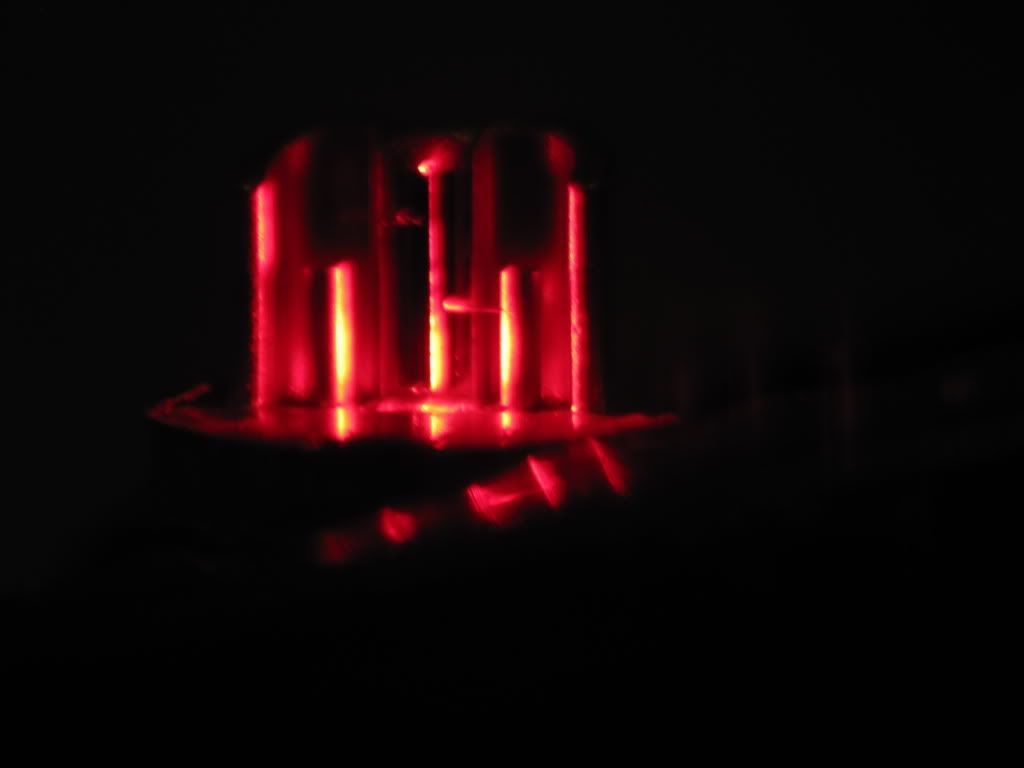

(12:10:17 AM) BobBoyce: in the above die shot you can see the pump energy leaking out along the side of the die, looks as if the die has broken loose from mechanical shock

(12:08:27 AM) BobBoyce: looks to be output optical coating damage Jimmy

I'm making a build for a friend, and I have a LPC-815 LOC diode hooked up to a "Groove Driver" at 330mA. The build is all finished, but the diode isn't working properly (it never was working since it was first powered at 330mA, driver tested). Instead of a nice round projection, the laser diode is emitting a odd triangle projection, and is very dim. So I buy another LPC-815 sled, extract the diode, hook up the driver, and the same thing. What could possibly cause this? Is it my extracting procedure? Below are some macro pictures and a picture of this odd triangle projection. Note that instead of the light being emitted from the tip of the diode, it is emitted from the center.

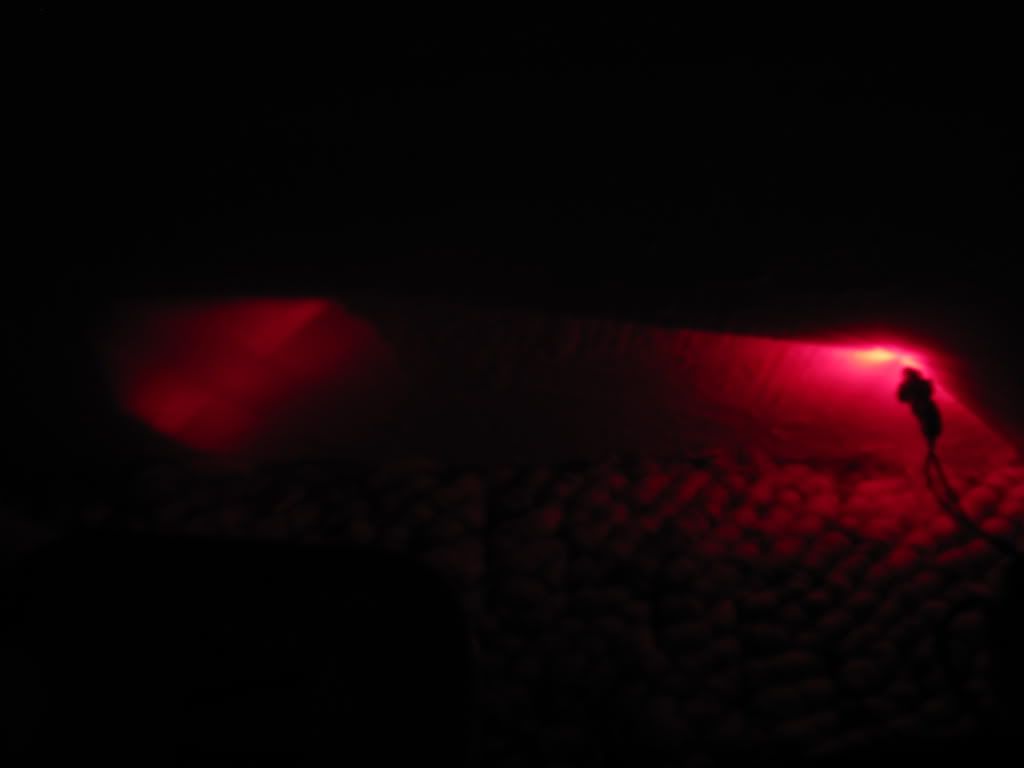

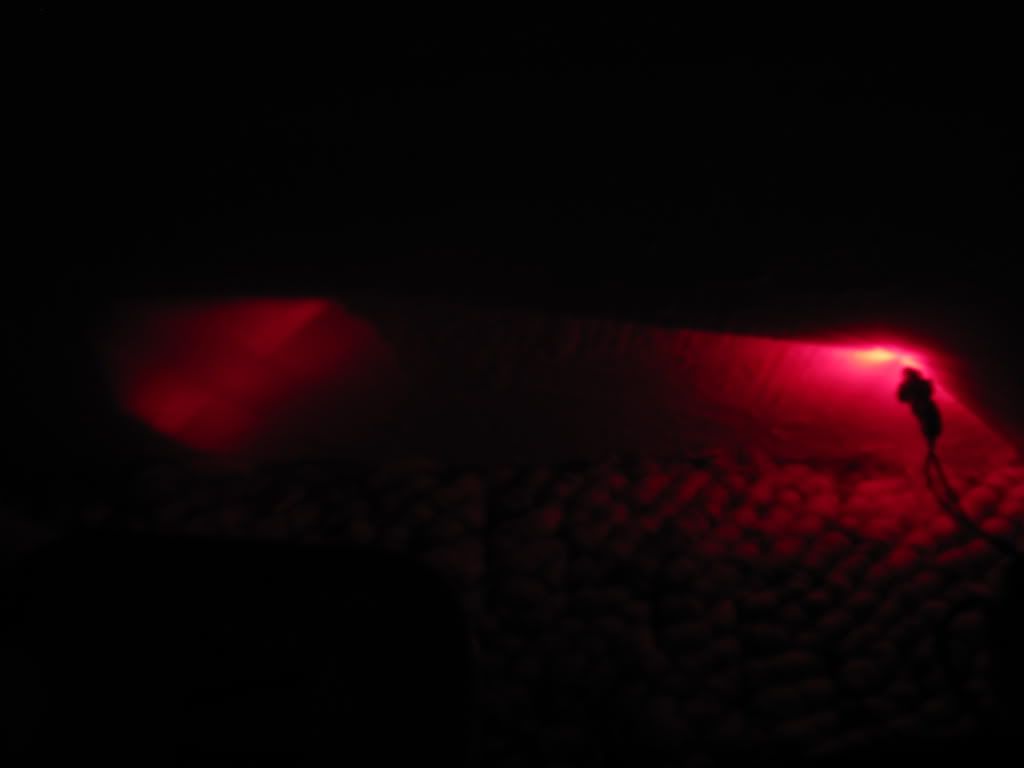

Normal diode (below lasing threshold) on the left, odd diode on the right. Both LPC-815

This next picture is not mine, but a nice picture of a lasing LOC diode.

I know I'm an experienced member, but this is just something that baffles me. 2 bad diodes in a row? Not right..

Thanks,

Jimmymcjimthejim

(12:23:35 AM) BobBoyce: the oc could just have indium splash on it causing the output malfunction

if you have a reflow station and a good magnifier, it is possible to use a small fine point and reseat the die while reflowing at about 110C

but it can even be seen in the unpowered photo the dark strip of the die side is exposed even when viewed from above

(12:15:07 AM) BobBoyce: if you heat a LD enough the indium will let loose

(12:16:09 AM) BobBoyce: it really does look like mechanical shock damage

(12:14:15 AM) BobBoyce: ok, the optical coating damage would be from too much drive current

(12:11:21 AM) BobBoyce: but the output end of the die appears to be damaged as well

(12:10:17 AM) BobBoyce: in the above die shot you can see the pump energy leaking out along the side of the die, looks as if the die has broken loose from mechanical shock

(12:08:27 AM) BobBoyce: looks to be output optical coating damage Jimmy

I'm making a build for a friend, and I have a LPC-815 LOC diode hooked up to a "Groove Driver" at 330mA. The build is all finished, but the diode isn't working properly (it never was working since it was first powered at 330mA, driver tested). Instead of a nice round projection, the laser diode is emitting a odd triangle projection, and is very dim. So I buy another LPC-815 sled, extract the diode, hook up the driver, and the same thing. What could possibly cause this? Is it my extracting procedure? Below are some macro pictures and a picture of this odd triangle projection. Note that instead of the light being emitted from the tip of the diode, it is emitted from the center.

Normal diode (below lasing threshold) on the left, odd diode on the right. Both LPC-815

This next picture is not mine, but a nice picture of a lasing LOC diode.

I know I'm an experienced member, but this is just something that baffles me. 2 bad diodes in a row? Not right..

Thanks,

Jimmymcjimthejim

Last edited: