You asked for back lens, not mirrors, I just understood I headed the wrong direction, but had already written text below, I need to know what diode or 808 nm source you are using to pump the rod, I might be able to point you in the correct direction, especially if fiber output 808.

Edited:

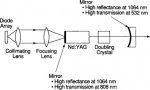

Illustrations: Below you will find a diagram of the diode pumped ND:YAG, they illustrate the laser diode portion without showing it has a collimation lens inside that box, earlier I couldn't understand how this arrangement shown in the left most drawning could work without a collimation lens first, but I can now see there is a cylinder lens in a horizontal position in front of the laser diode. The only way a pair of cylinder lenses can correct a rectangle shaped laser diode beam into more of a square (approximating a dot), is if it is collimated first, they do not show the collimation lens, only the first cylinder lens as a small bump attached to the laser diode mount.

The second diagram to the right is without beam shaping. If you are using a diode array like are used in a FAP800, for myself, I wouldn't want to tackle that one, although I would not be afraid of a FAP800 with their nice small fiber output. Regarding the diagram on the left again, for other applications, a benefit of beam shaping a diode output is to increase the power density, and I am assuming this is what they are doing to pump the YAG too, but it may merely be to make the beam more uniform into the YAG. I need to study pumping YAG rods more to get a proper understanding of the benefit of beam shaping a pump diode output, I might be over speculating.

Fig. 1 Diode (end) pumped Nd:YAG laser schematic

I am working on the same thing, but my rod is already multicoated, if you can find a rod like that, maybe it would make things easier in some respects. According to the seller I bought my rod from, I am hoping they are coated to AR and pass 808 nm on the input end, they are also coated for 1319 nm, that is the wavelength I want to produce. I am building a database for this and other DPSS projects at laserhobbyist but not a lot there yet, better to go to

http://donklipstein.com/lasercds.htm#cdstoc

This is what the seller told me about the coatings:

Definitely AR for 1319, possibly also HT 808 for end pumping (which would be unusual for a rod of this length). Also possibly HR for 1064nm since you need to suppress gain at 1064 to get lasing at 1319. That's usually done in the cavity mirrors though. Or maybe even HR 660 to keep any doubled light out of the gain stage.

You can probably extract some of the information you are wanting from his message, above. If I cannot end pump it, that's fine, I will side pump it. What I have found for a 1064 nm ND:YAG to SHG to 532 nm is the rod needs HR or high reflectivity for both 1064 nm and 532 nm on one end, external mirrors (or I suppose a mirror coated on the rod, but I am still learning about that) and on the other end an OC partial mirror for 1064 nm and high pass for 532 nm (intracavity SHG crystal) which allows only a percentage of the 1064 nm energy out, but all of the green without much loss.

Note: To produce green using a ND:YAG you should have the crystal inside the cavity, and even better also have a Q-switch inside. If the crystal is outside of the cavity of a CW laser the conversion to green is very weak, if you can see any at all which is more often the case. Although if the rod is Q-switched through some technique, you can have the crystal located outside, but it requires a lot of peak pulse power to have much efficiency when the crystal is on the outside. I have tried to get green out of a KTP crystal using a 2 watt 1064 nm CW pointer and only saw a faint spot of green on the surface of the input end, no apparent beam at all and the crystal itself did not light up either, no matter the angle which just now brings to mind the likely problem, the output of that pointer probably is not polarized, I need a type II crystal for unpolarized.

We have some experienced members who can likely clarify some of this and better advise, hoping they will chime in. There are different techniques, depending upon what your application is.

Note: First paragraph regarding the illustrations edited.